Microstrip slow-wave structure transmission system suitable for wide dielectric substrate

A medium-substrate, slow-wave structure technology, used in waveguides, waveguide-type devices, circuit components of transit-time electron tubes, etc. problems, to achieve the effect of improving transmission performance, filtering out waveguide modes, and overcoming reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

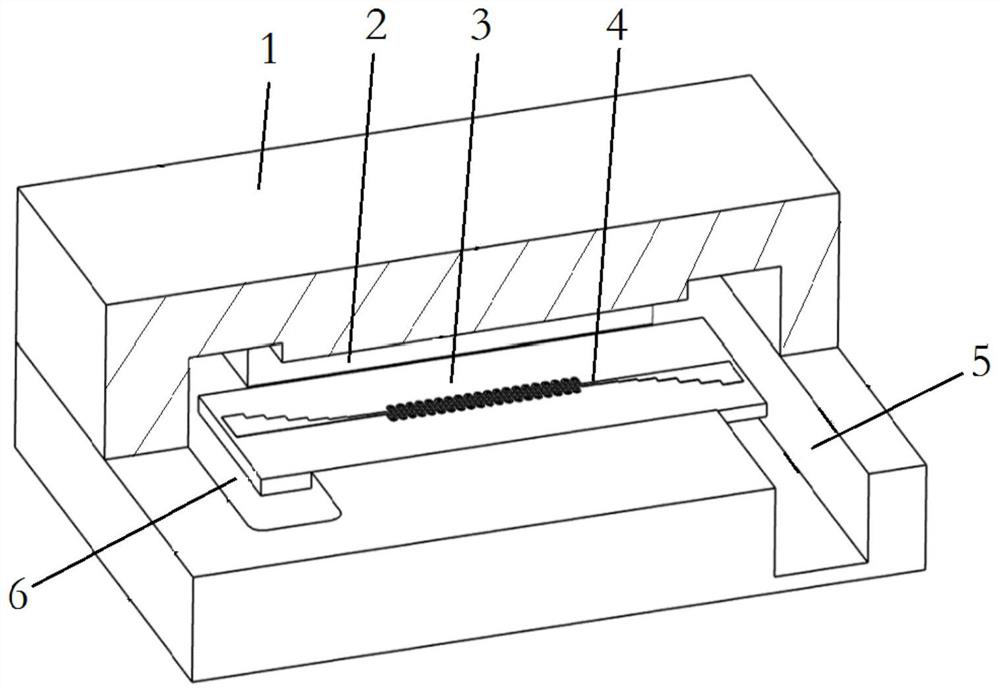

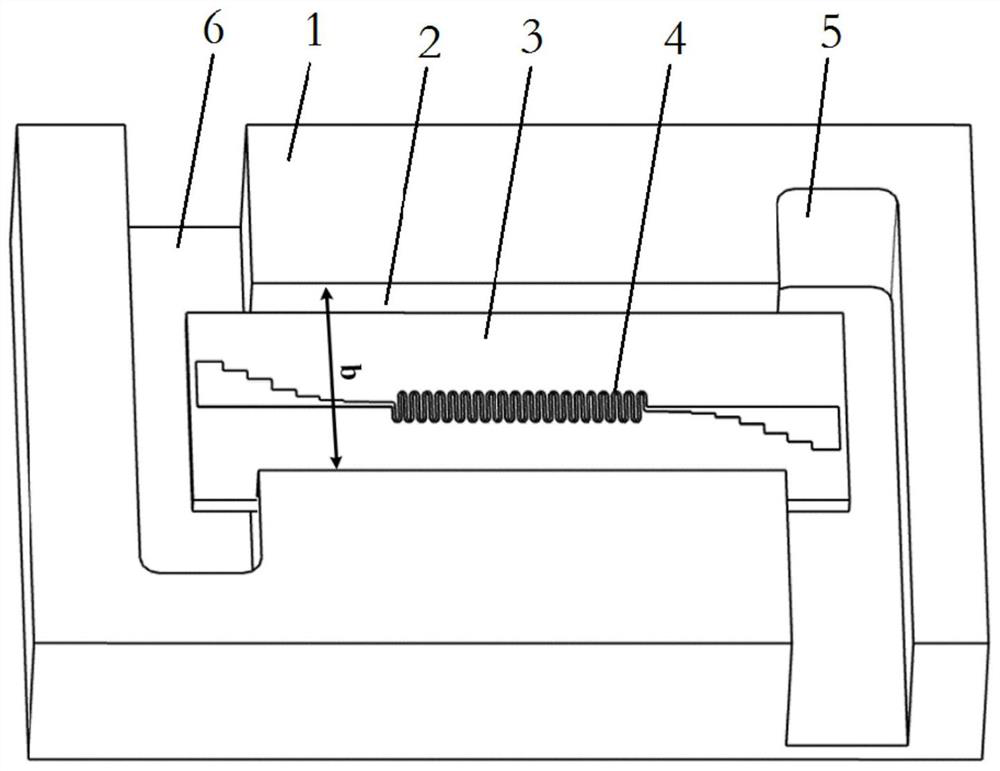

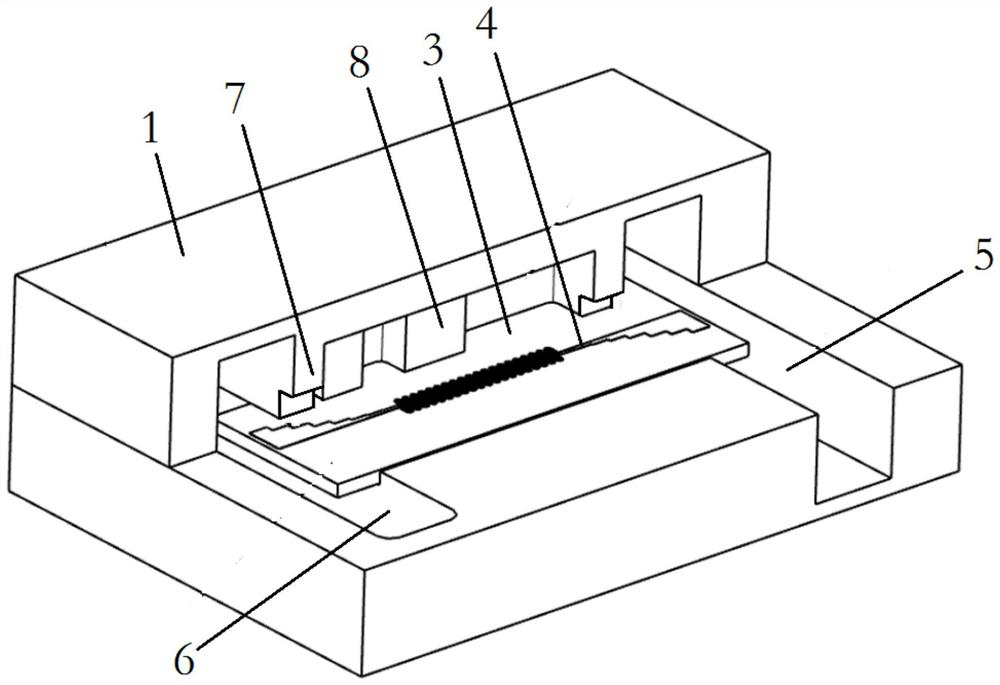

[0038] Embodiment: a kind of microstrip slow-wave structure transmission system suitable for wide dielectric substrate 3, such as image 3 and Figure 4 As shown, it includes a metal casing 1 and a dielectric substrate 3 provided with a microstrip slow wave line 4. The metal casing 1 is provided with a vacuum chamber 2, an input waveguide 5, and an output waveguide 6. The dielectric substrate 3 is installed in the vacuum chamber 2, and The two ends of the dielectric substrate 3 are respectively placed in the input waveguide 5 and the output waveguide 6, and the side wall of the vacuum chamber 2 is provided with two sets of first protrusions 7 and two sets of second protrusions 8, two sets of first protrusions 7 and two sets of The second protrusions 8 are all located on the side of the dielectric substrate 3 where the microstrip slow wave line 4 is disposed. Two groups of first protrusions 7 and two groups of second protrusions 8 are arranged at intervals along the microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com