Fluidized bed electrode solid oxide fuel cell device

A solid oxide and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of reducing anode catalyst activity and reaction stability, decreasing energy conversion efficiency, complex external heating devices, etc. , to achieve the effects of improving energy conversion efficiency, increasing space utilization, and improving heat transfer and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

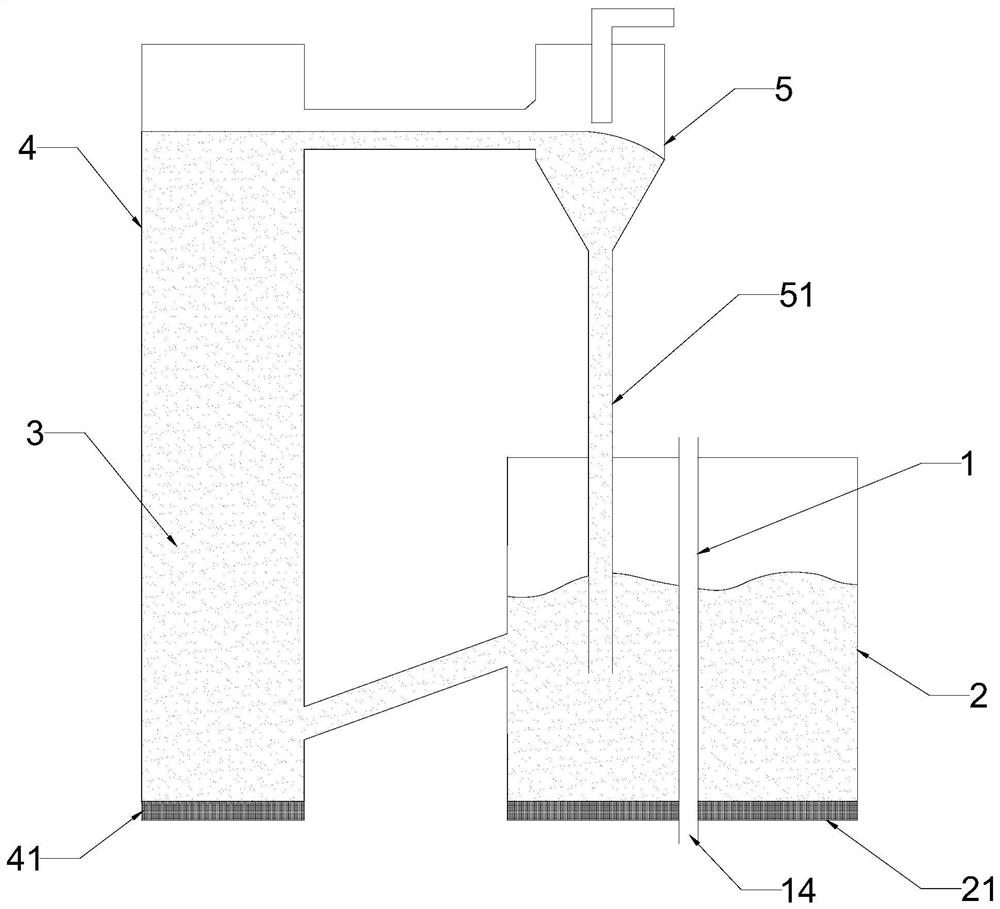

[0021] Embodiment one: if figure 1 As shown, preferably, it also includes a circulating fluidized bed 4 and a cyclone separator 5, the bottom of the circulating fluidized bed 4 is provided with a second air inlet 41, and the upper part of the circulating fluidized bed 4 communicates with the upper part of the cyclone separator 5 , the lower part of the circulating fluidized bed 4 communicates with the bubbling fluidized bed 2, the discharge pipe 51 at the lower part of the cyclone separator 5 is inserted into the bubbling fluidized bed 2, and the electrode particles 3 are in the bubbling fluidized bed 2, the circulating flow Circulating flow in bed 4 and cyclone separator 5. There is one battery body 1 arranged on one side. The first air inlet 14 and the second air inlet 41 are provided with air distribution plates, and the air distribution plates can only allow air to pass through. The anode 12 and electrode particles 3 are made of nickel oxide-yttria stabilized zirconia. ...

Embodiment 2

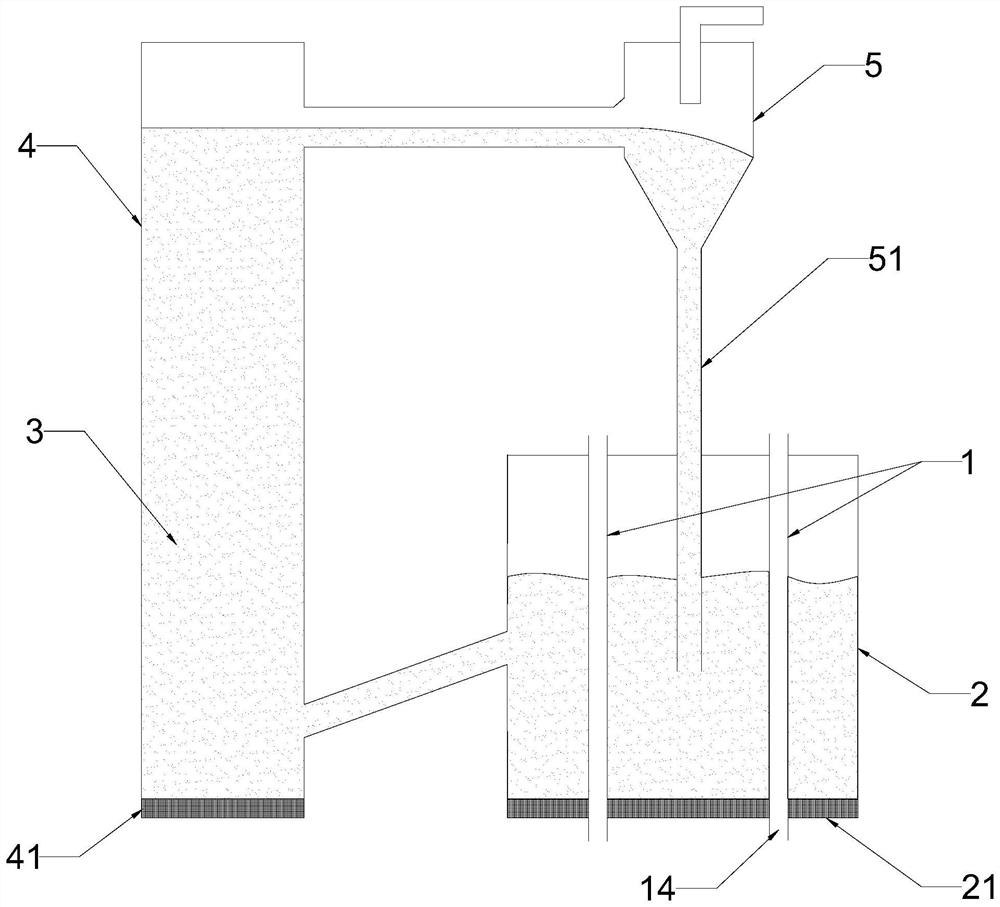

[0022] Embodiment two: if figure 2 As shown, preferably, there are two battery bodies 1 , which are symmetrically arranged on both sides of the discharge pipe 51 at the lower part of the cyclone separator 5 . All the other structures are the same as in Embodiment 1.

[0023] Working process and principle of the present invention are as follows:

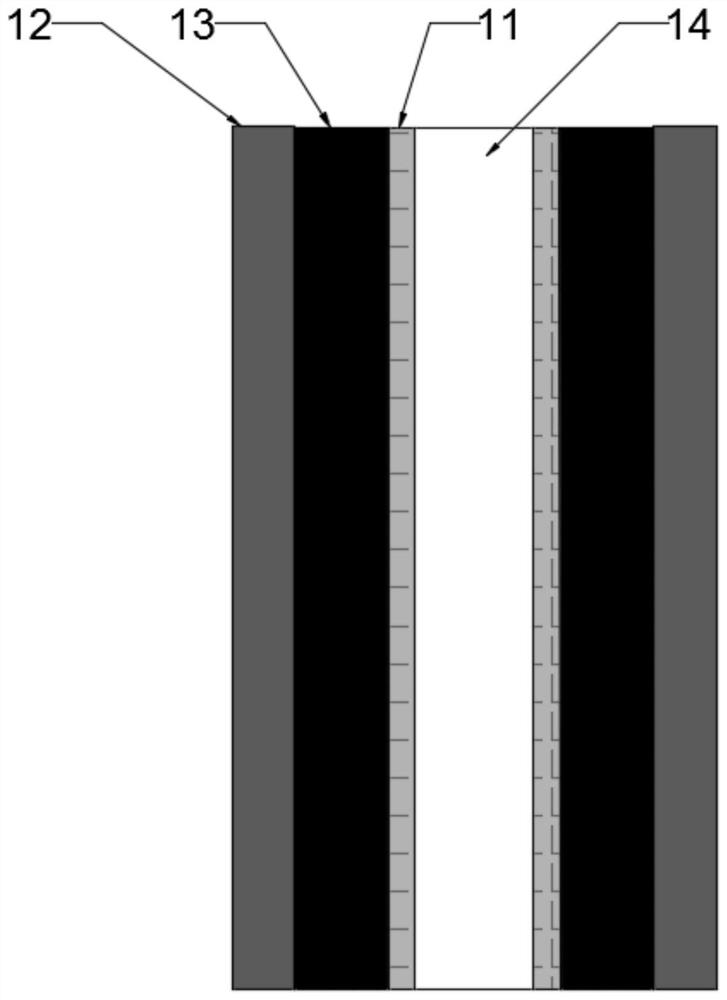

[0024] (1) The battery body 1 is composed of a cathode 11 , an electrolyte layer 13 and an anode 12 , and is connected to a load through an external wire. The fuel gas enters from the fuel gas inlet 21 at the lower part of the bubbling fluidized bed 2 and diffuses to the anode 12 side of the battery body 1, and the air enters from the first air inlet 14 and diffuses to the cathode 11 side of the battery body 1, The electrochemical reaction takes place in the bubbling fluidized bed 2 . Among them, the reduction reaction occurs on the cathode 11 side, and the oxygen in the air reacts under the action of the cathode 11 to generate O ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap