Commutator forming mold

A technology for forming molds and commutators, applied in the field of commutators, can solve problems such as vaporization, copper sheet deformation, and physical injury to operators, and achieve the effects of maintaining permeability, improving efficiency, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

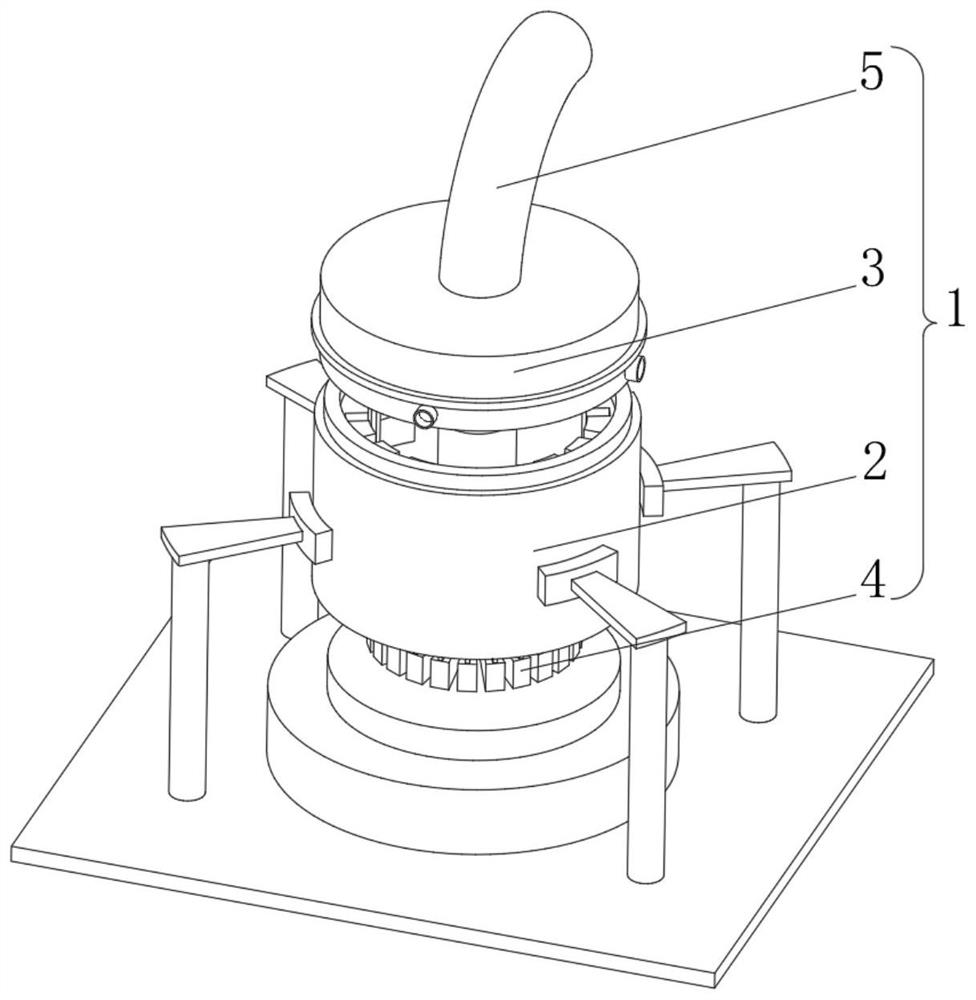

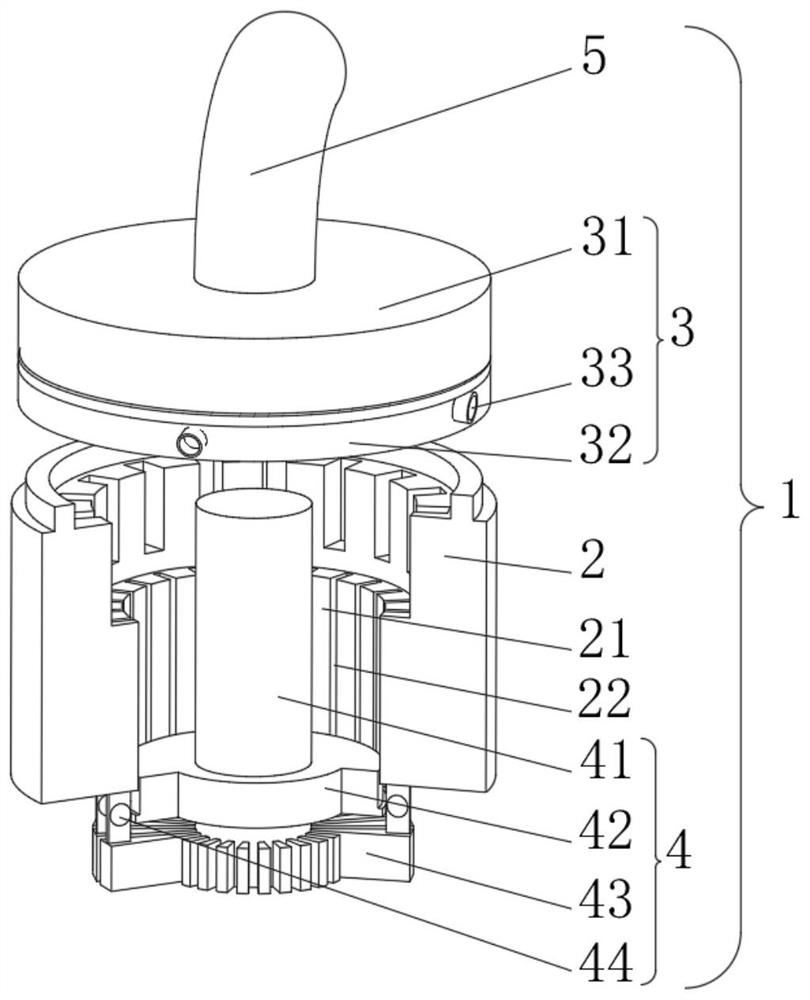

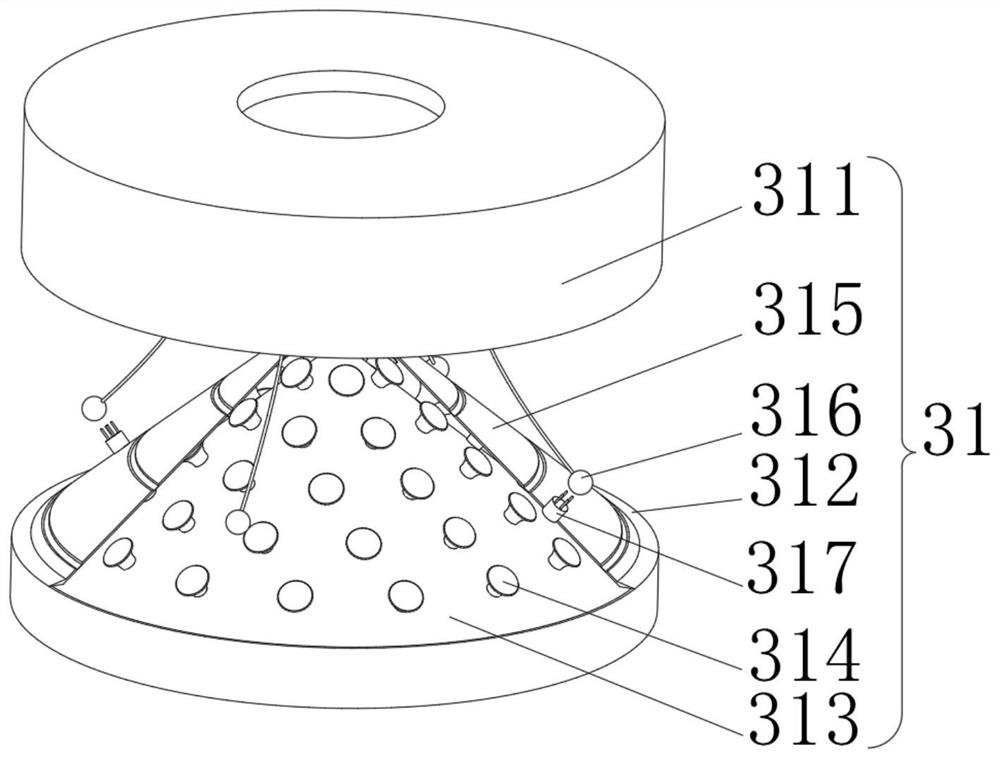

[0040] Embodiment: A kind of commutator molding mold, comprises the commutator injection molding mold body 1 that fixed mold 2, movable mold 3, ejector 4 and exhaust pipe 5 are formed, the bottom of movable mold 3 and the bottom of fixed mold 2 The top is threaded, the demoulding device 4 is located inside the fixed mold 2, the bottom end of the suction pipe 5 is connected with the inside of the movable mold 3, the top of the suction pipe 5 is connected with the external air extractor, and the inside of the fixed mold 2 is respectively opened There are injection molding holes 21 and injection molding grooves 22. The stripper 4 includes a middle solid rod 41. The bottom of the middle solid rod 41 is fixedly connected with a limit plate 42. The outer side of the limit plate 42 is slidingly connected with the inner wall of the injection hole 21. The limit plate The bottom of 42 is fixedly connected with lifting plate 43, the bottom of lifting plate 43 is fixedly connected with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap