Manual hydraulic cigarette making equipment

A technology for cigarettes and equipment, applied in the field of manual hydraulic cigarette making equipment, can solve the problems of unfavorable cleaning, high manufacturing cost, insufficient pressing material, etc., so as to improve the service life and operation safety, reduce the transmission loss ratio, and improve the precision. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

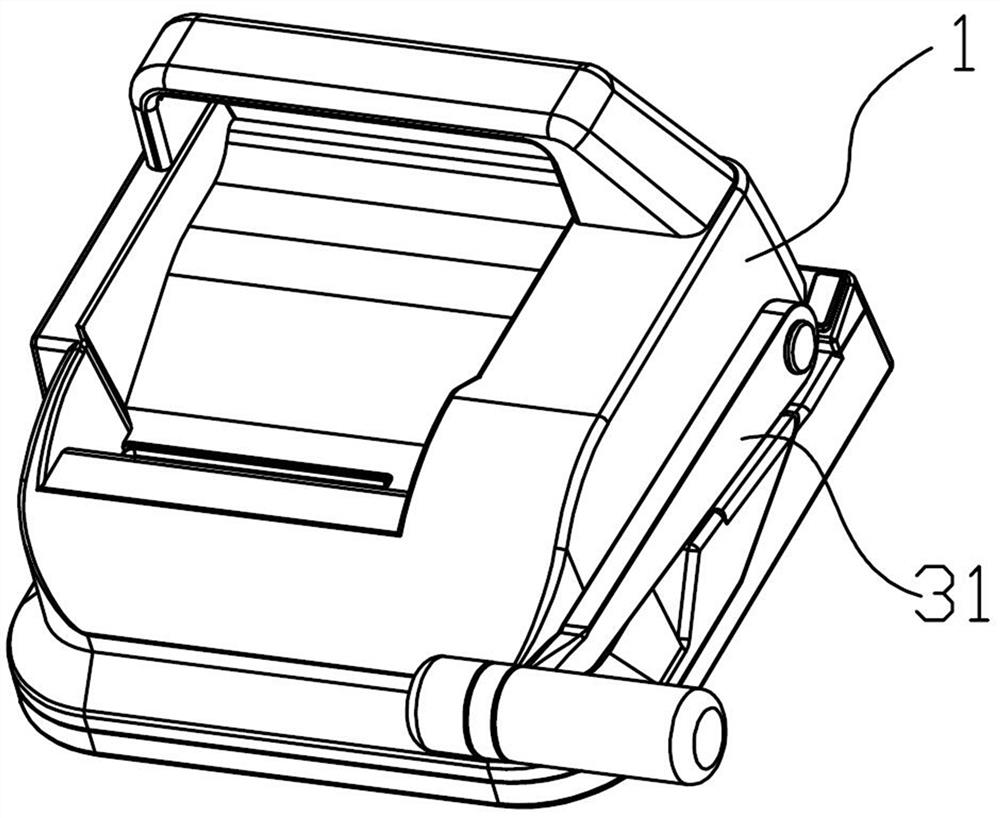

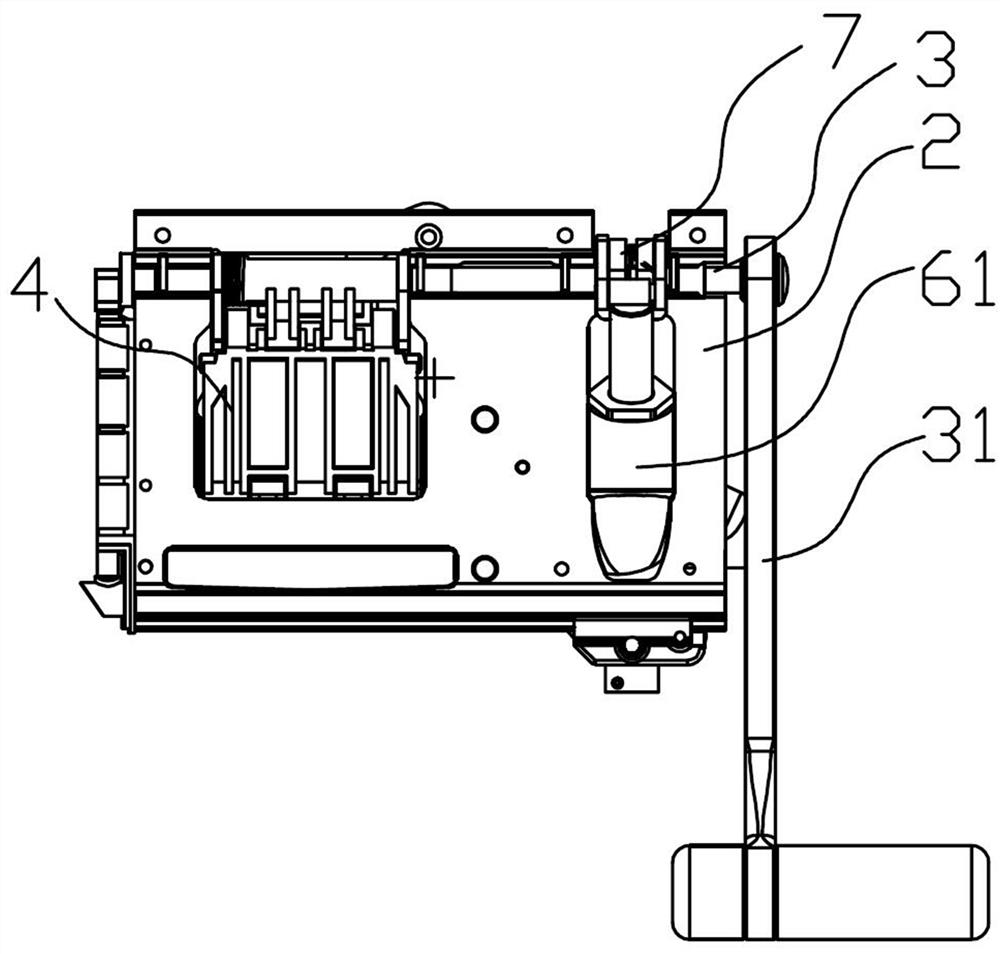

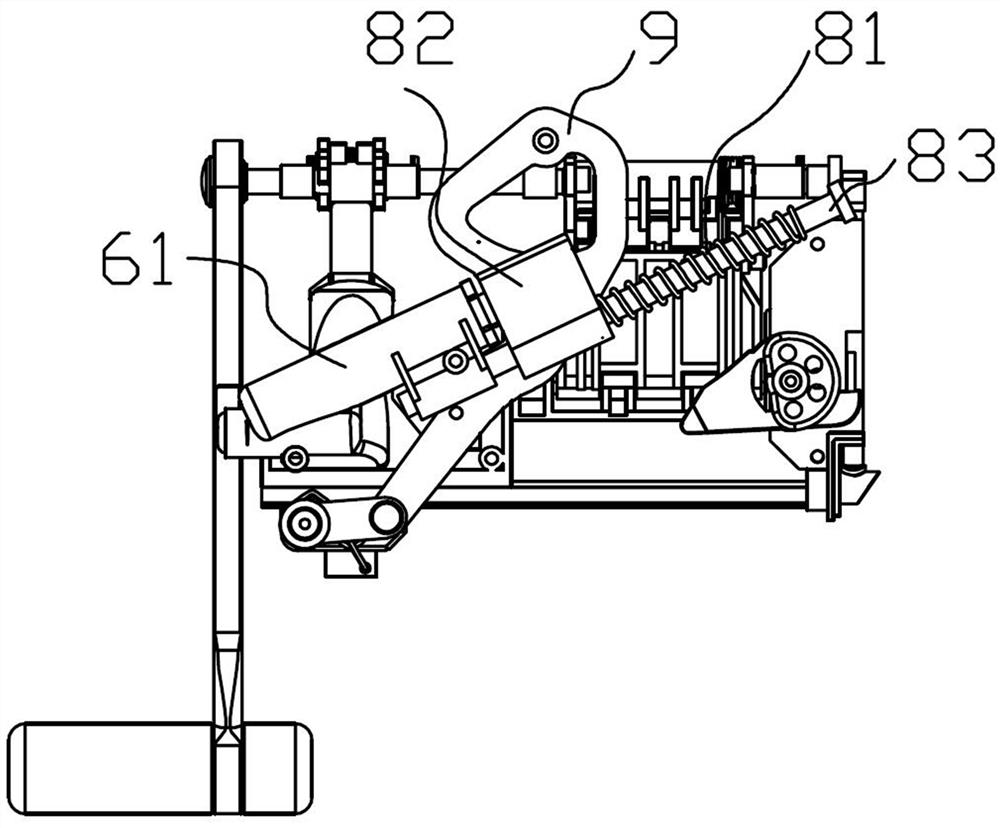

[0029] A manual hydraulic cigarette making equipment, such as Figure 1-6 As shown, it includes a casing 1 and a frame body 2 arranged in the casing 1, and the frame body 2 is provided with a drive shaft 3, a pressing assembly 4, a discharge spoon 5, a transmission assembly, a swing arm 9, and a pushing assembly 7 . Rebound assembly; the driving shaft 3 is connected with a handle 31 and rotates under the drive of the handle 31; the pressing assembly 4 includes a pressing plate 41 that can reciprocate along the y-axis direction, and the pressing plate 41 is used for pressing and forming shredded tobacco , the pressing assembly 4 is connected to the driving shaft 3 through transmission, the driving shaft 3 rotates and drives the pressing plate 41 to move; the discharge spoon 5 can be pushed out and retreated along the x-axis direction in the frame body 2, and is used to push out the formed shredded tobacco; The transmission assembly includes a hydraulic cylinder 61 and a first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com