Novel small-pipe-diameter thread machining chip removal tool

A thread processing, small diameter technology, applied in the direction of thread cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems of accelerated tool wear, tool chipping, and difficulty in chip removal of small diameter threads, so as to solve the problem of chip removal. Difficulty, improve the service life, and the effect of the diversity of the installation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

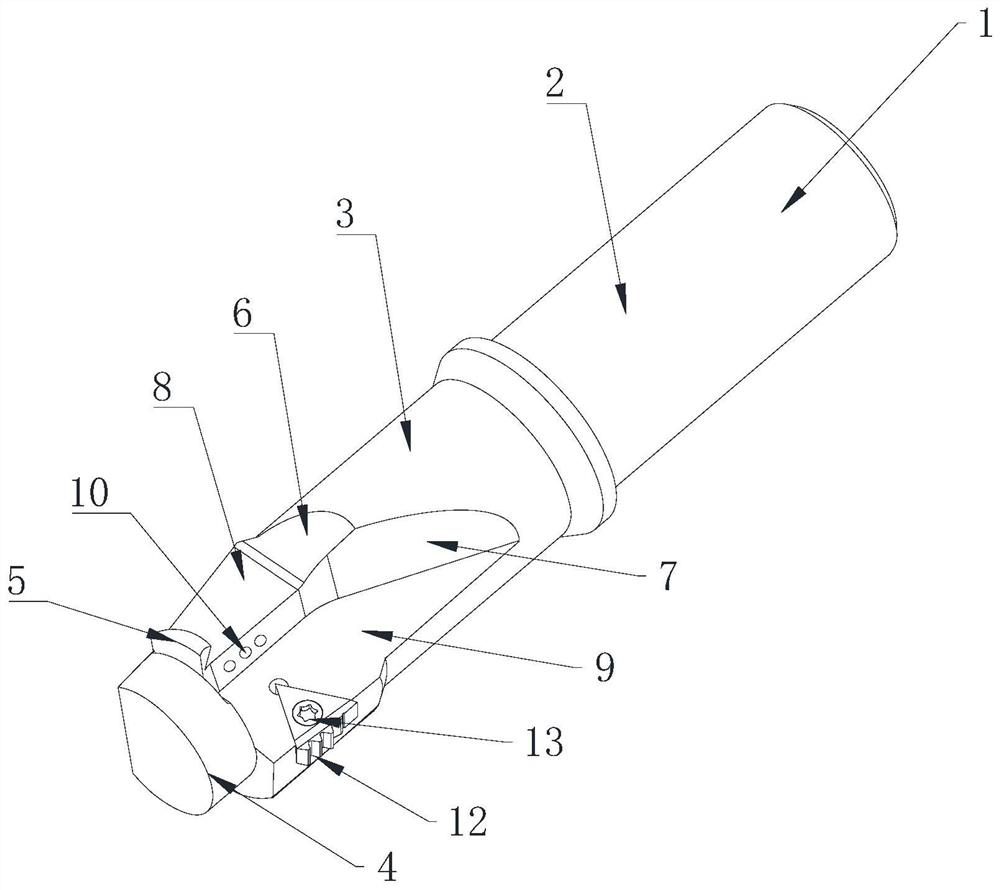

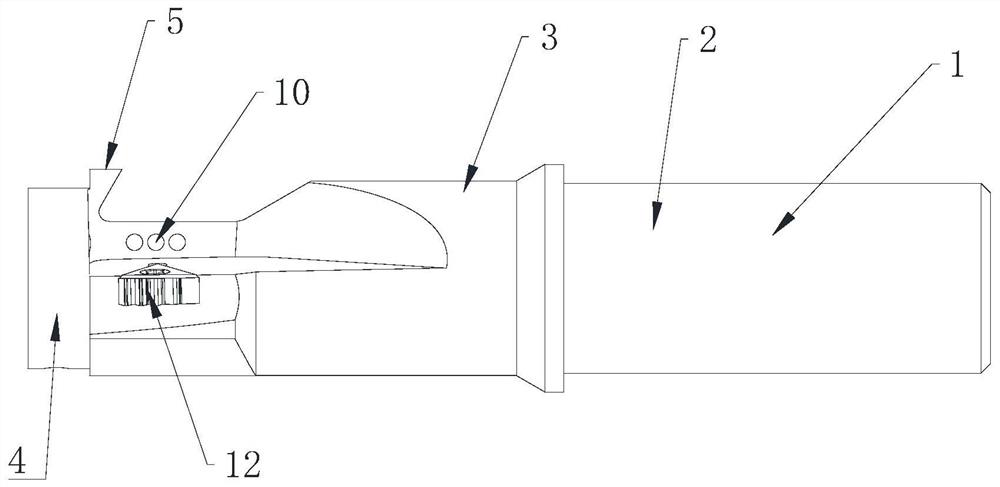

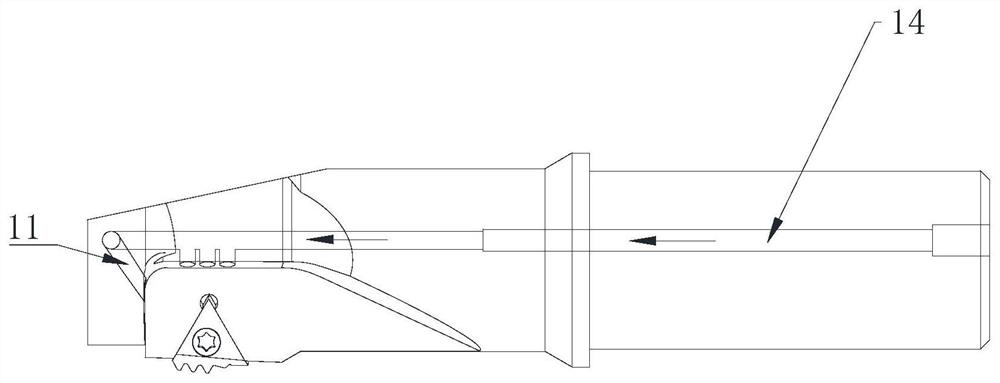

[0024] A new type of chip removal tool for thread processing with small diameter, such as figure 1 , figure 2 , image 3 As shown, it includes a mounting part, a cutting part and a cooling part. The cutting part and the cooling part are respectively installed on the mounting part. The mounting part includes a handle. Equipment, the cutting part includes blades, blade mounting grooves and blade fasteners, the blades are installed in the blade mounting grooves through the blade fasteners, the blade mounting grooves can be adjusted according to the blade structure, the cooling part includes cooling channels, and the cooling channels are along the blade The shank is arranged in the axial direction, and the mounting part is also processed with a winding part for the concentrated winding of linear metal chips generated during processing and a chip removal part for discharging granular metal particles. The structure of this embodiment is integrally formed.

[0025] The winding pa...

Embodiment 2

[0028] The difference from Embodiment 1 is that the length of the first platform is 32mm. If the first platform is too small, it will affect the chip hooking effect, and if it is too large, it will affect the rigidity of the tool. At this time, both the rigidity of the tool and the hooking of the chip groove can be ensured. Crumbs work best and achieve balance.

Embodiment 3

[0030] The difference from Example 1 is that the distance between the boss and the chip slot is 0 mm, the boss is the chip stopper, the side of the boss close to the first platform is the chip surface, and the distance between the chip surface and the first platform is The included angle is 90°, and the boss and chip slot together form a right-angle slot structure, which can also realize the chip hooking function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com