A high-strength corrugated paper sealing process

A sealing process and corrugated paper technology, applied in the field of corrugated paper, can solve problems such as failure to meet high-strength pressure, falling off or tearing of the sealing position, unfavorable use of corrugated cartons, etc., to increase the adhesive strength of the colloid, improve stability, and improve sealing. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

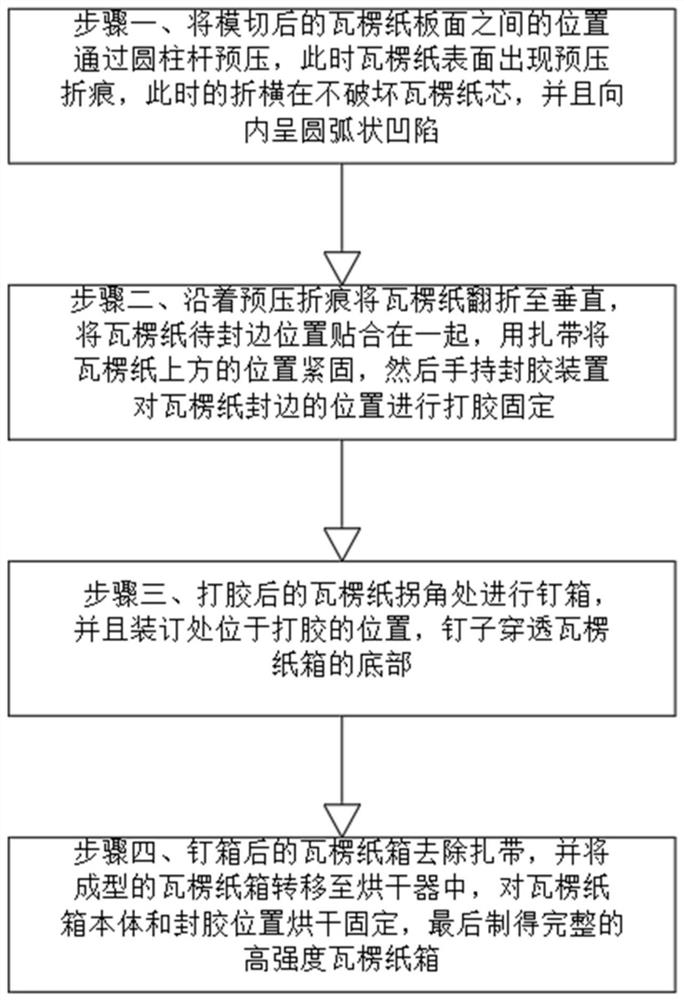

[0037] like figure 1 As shown, the present invention provides a technical solution: a high-strength corrugated paper sealing process, characterized in that it consists of the following steps:

[0038] Step 1. Pre-press the position between the die-cut corrugated cardboard surfaces through cylindrical rods. At this time, pre-pressed creases appear on the corrugated cardboard surface. At this time, the folds do not damage the corrugated cardboard core, and the inward arc-shaped depressions ; Make the corrugated paper have a tendency to bend inward first, so as to avoid the bending of the corrugated paper to the outside.

[0039] Step 2: Fold the corrugated paper vertically along the pre-pressed crease, attach the corrugated paper to be edge-sealed together, fasten the position above the corrugated paper with cable ties, and then hold the sealing device to seal the edge of the corrugated paper. Glue fixation; multiple fixation at the seal to improve the working strength of the c...

Embodiment 2

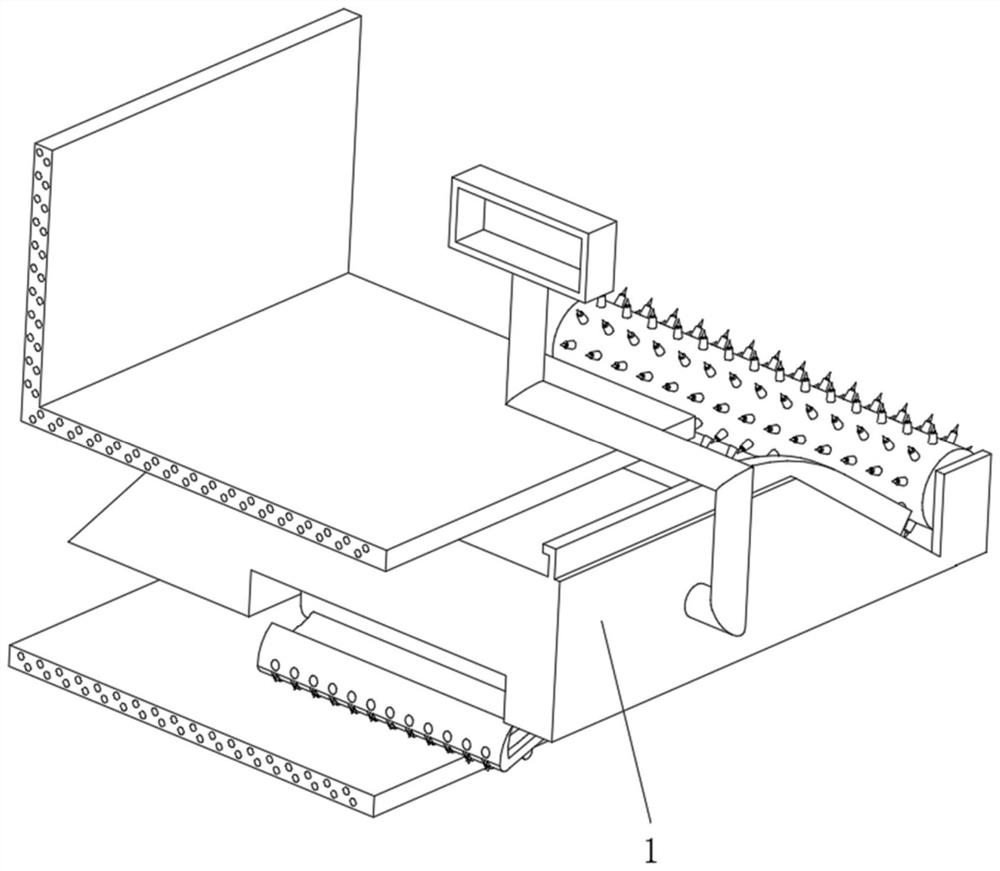

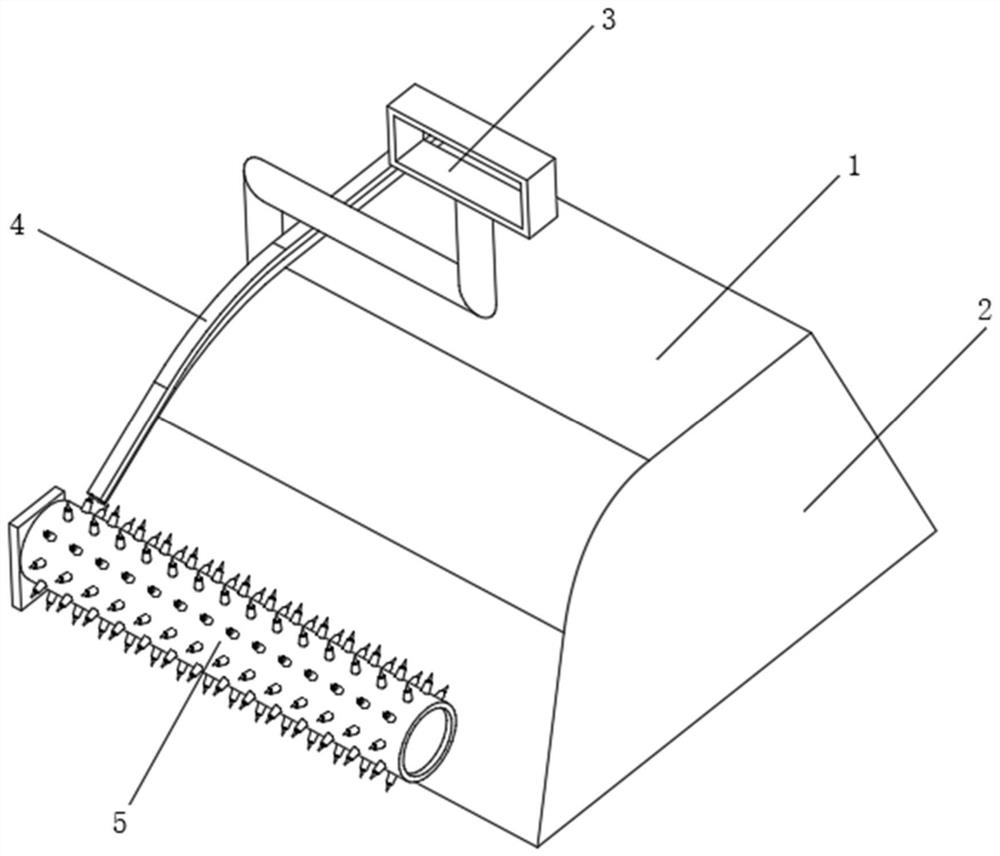

[0043] like Figure 2-6As shown, on the basis of the first embodiment, the present invention provides a technical solution: a high-strength corrugated paper sealing process. There is a guiding oblique block 2 on the front, a driving handle 3 is arranged above the glue counterweight 1, a limit card 4 is fixedly connected to the back of the top of the glue counterweight 1, and the left side of the glue counterweight 1 is rotated and connected There is a reinforced glue roller 5 , a movable groove 6 is arranged in the middle position of the bottom of the glue counterweight 1 , and a processing mechanism 7 is arranged inside the movable groove 6 .

[0044] The reinforced glue roller 5 includes a contact shell 51 , the shaft center of one end of the contact shell 51 is rotatably connected with the glue counterweight 1 , the inner center position of the contact shell 51 is fixedly connected with a storage tank 52 , and the middle position outside the contact shell 51 is connected. ...

Embodiment 3

[0047] like Figure 7-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a high-strength corrugated paper sealing process. Internally rotationally connected, an elastic air bag 72 is fixedly connected to the inner top of the movable slot 6 and located above the driving pendulum rod 71, and the end of the driving pendulum rod 71 away from the movable slot 6 is fixedly connected to a contact processing rod 73. The output end communicates with the contact processing rod 73 through the conducting conduit 74 . Indent the surface of the corrugated cardboard, where the indentation corresponds to the corrugated paper above, to ensure that the two corrugated papers fit each other during sealing, avoid the offset of the sealing glue, and improve the stability of the sealing connection.

[0048] A feed pump groove 75 is fixedly connected to the bottom end of the right side of the elastic air bag 72 and located below the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com