Method for preparing lithium triborate seed crystal

A technology of lithium triborate and seed crystals, which is applied in the field of preparation of lithium triborate seed crystals, can solve the problems of platinum wire seeding, which is prone to miscellaneous crystals, affects the quality of lithium triborate crystals, and the overall process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

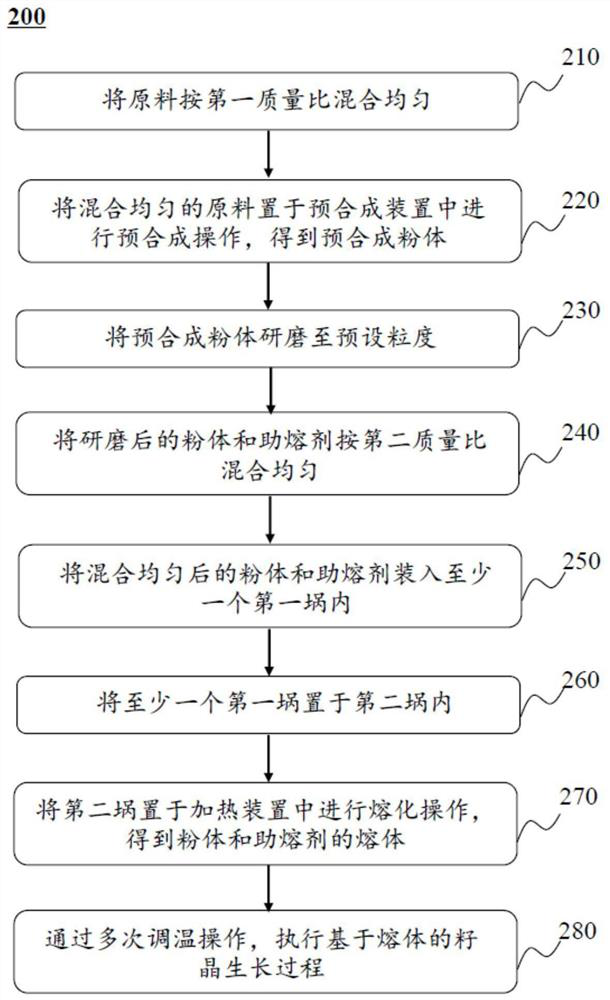

Method used

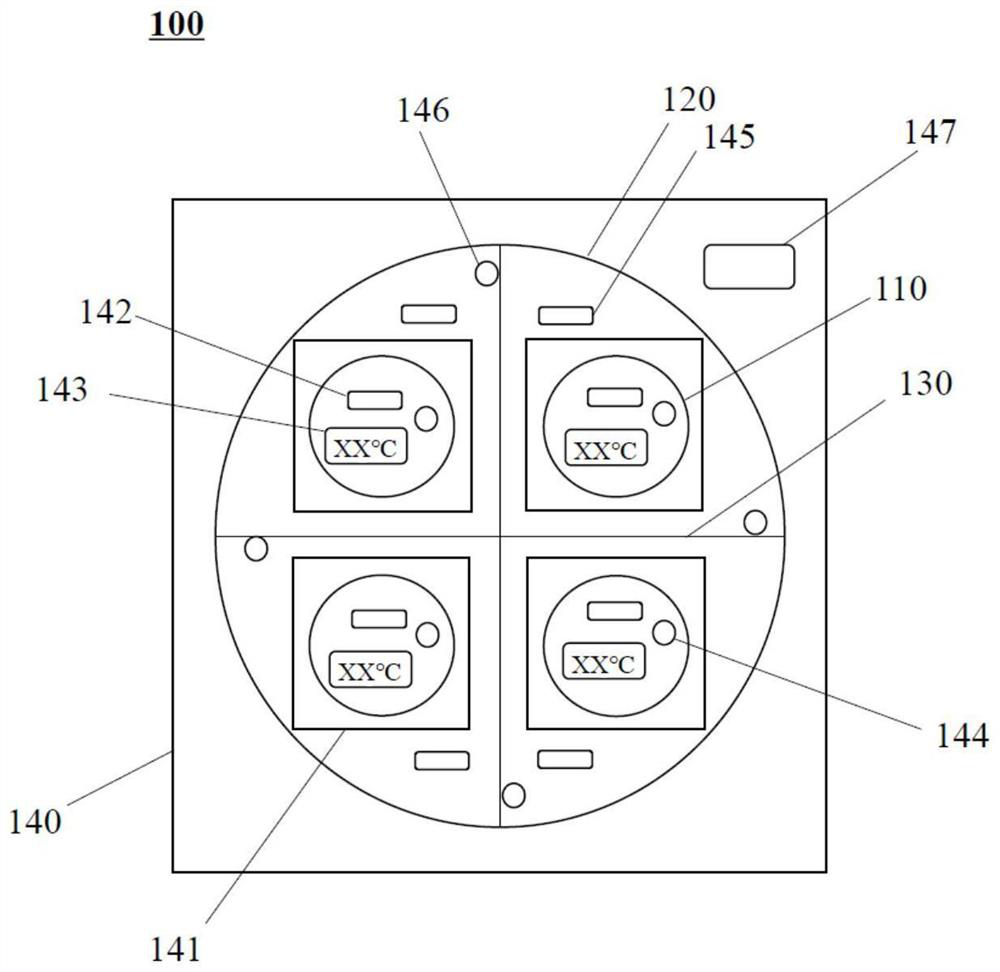

Image

Examples

Embodiment 1

[0147] Step 1: Mix 20g of lithium carbonate and 80g of boric acid raw materials through an agate mortar. Put the uniformly mixed raw materials into a corundum crucible and place it in a muffle furnace. Raise the temperature of the muffle furnace to 770°C at a rate of 5°C / min, keep the temperature for 30h, and obtain the pre-synthesized powder after cooling.

[0148] Step 2: Grind the pre-synthesized powder to less than 0.15mm. 10g of ground pre-synthesized powder and 90gLi 4 Mo 5 o 17 The flux is mixed evenly with an agate mortar. Put the uniformly mixed pre-synthesized powder and flux into the platinum crucible, then place the platinum crucible in the corundum crucible, put the crucible cover on the corundum crucible and put it into the muffle furnace. Heat the muffle furnace to 750°C at a heating rate of 1°C / min and keep the temperature for 24 hours to completely melt the raw materials.

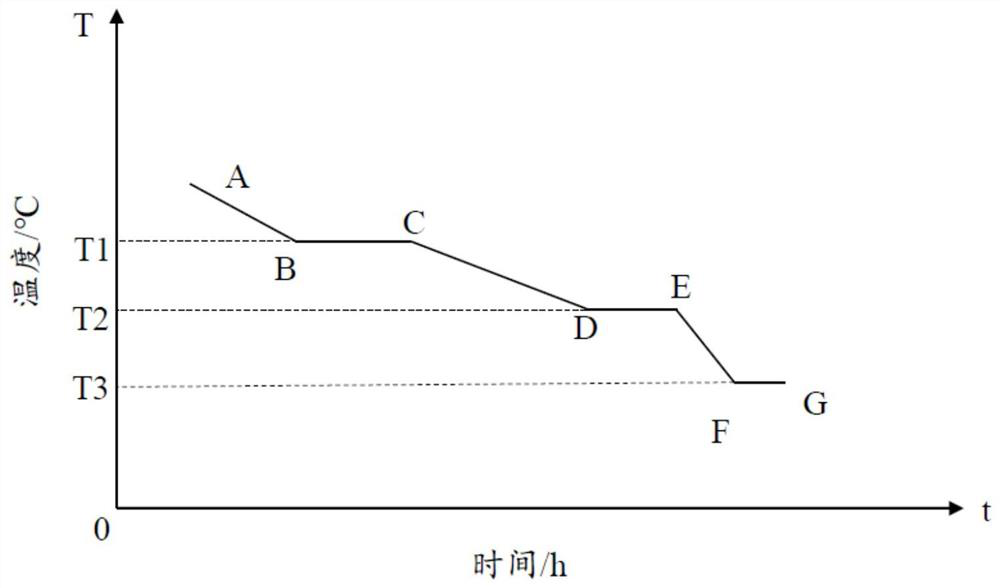

[0149] Step 3: Cool the muffle furnace down to 720°C at a cooling rate of 10°C / h,...

Embodiment 2

[0153] Step 1: Mix 24g of lithium carbonate and 76g of boric acid raw materials through an agate mortar. Put the uniformly mixed raw materials into a corundum crucible and place it in a muffle furnace. Raise the temperature of the muffle furnace to 780°C at a rate of 4°C / min, keep the temperature for 35h, and obtain the pre-synthesized powder after cooling.

[0154] Step 2: Grind the pre-synthesized powder to less than 0.15mm. 25g of ground pre-synthesized powder and 75gLi 2 MoO 4 The flux is mixed evenly with an agate mortar. Put the uniformly mixed pre-synthesized powder and flux into the platinum crucible, then place the platinum crucible in the corundum crucible, put the crucible cover on the corundum crucible and put it into the muffle furnace. Heat the muffle furnace to 780°C at a heating rate of 1°C / min and keep the temperature for 12 hours to completely melt the raw materials.

[0155] Step 3: Cool the muffle furnace down to 750°C at a cooling rate of 10°C / h, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com