Scaffold easy to disassemble

A scaffolding, easy-to-remove technology, applied in the field of scaffolding, can solve the problems of reducing the safety of the scaffolding, easy to shake, and increase the connection structure, so as to improve the supporting point and fixing effect, increase the flexibility and safety, and improve the operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

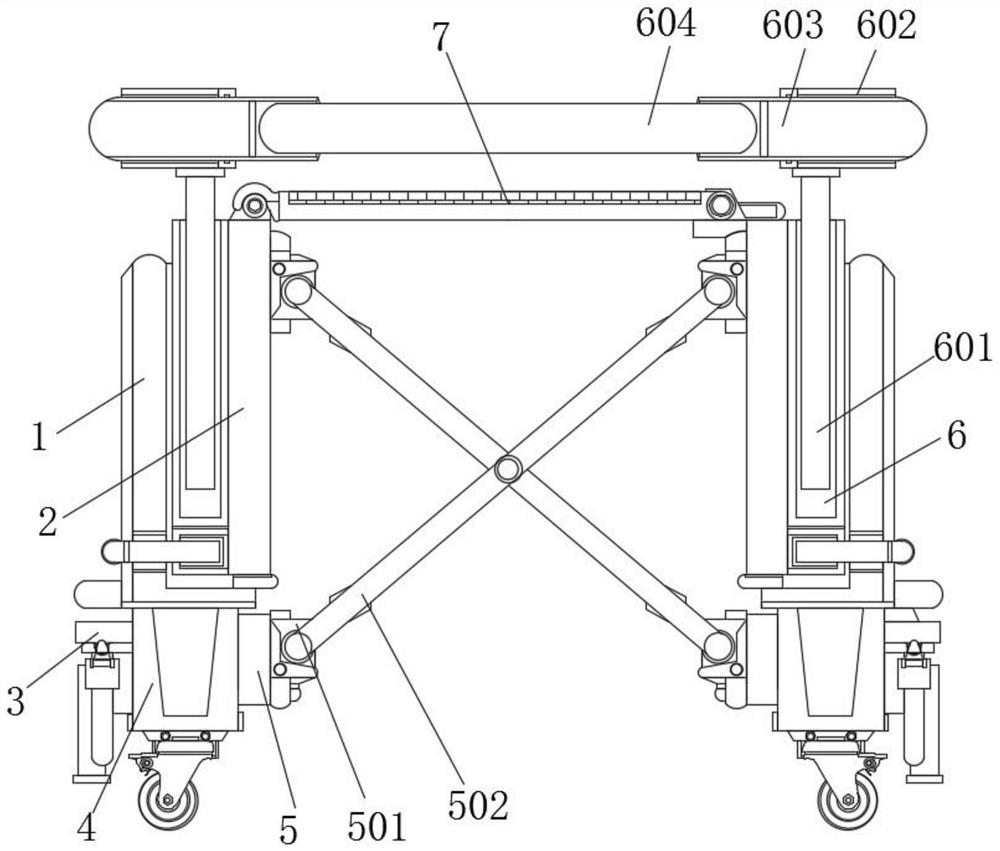

[0046] Example 1, such as Figure 1-4 As shown, when the scaffold is unfolded and folded, the protective conduit 604 slides along the inner wall of the arc-shaped guide sleeve 603 through the fit of the arc-shaped guide sleeve 603 and the protective conduit 604, but will not break away from the arc-shaped guide sleeve 603. Inside, when the scaffold is unfolded, the guide block 602 can be pushed to drive the sleeve rod 601 to guide and lift on the inside of the sleeve 6, so that the height of the protective conduit 604 can be adjusted, and the lifting position of the sleeve rod 601 can be adjusted through the positioning bolts. When it is fixed, a protective fence structure can be formed above the scaffold to protect the staff above the scaffold and increase the functionality and safety of the device.

Embodiment 2

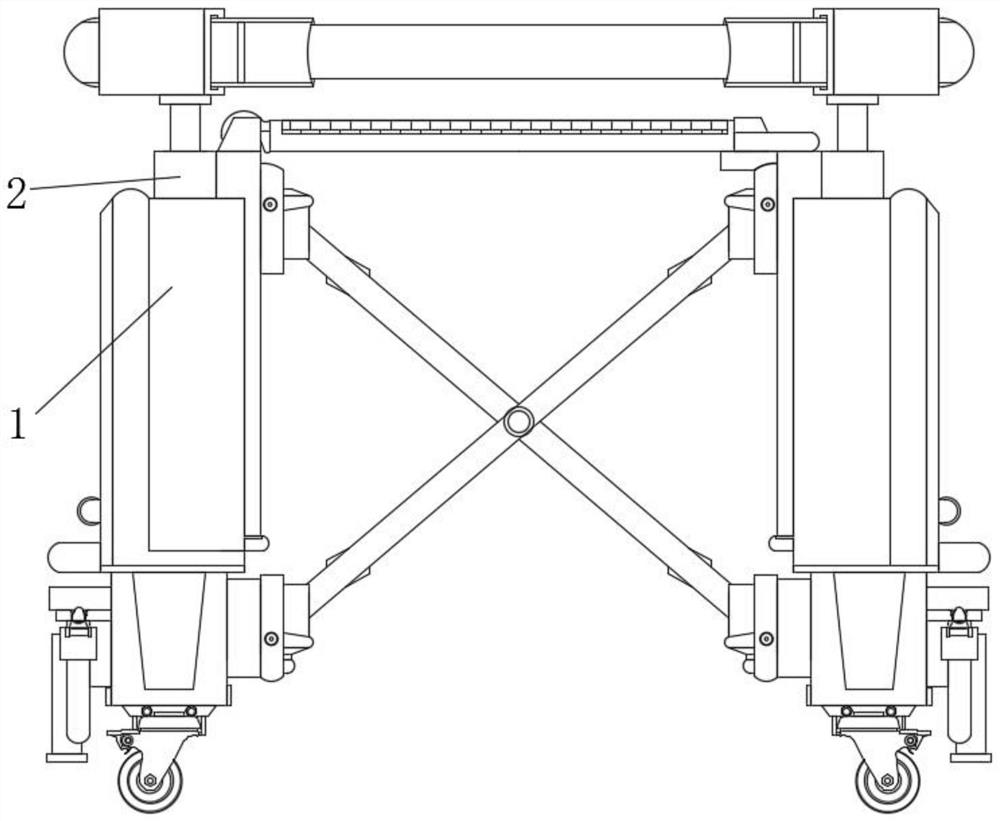

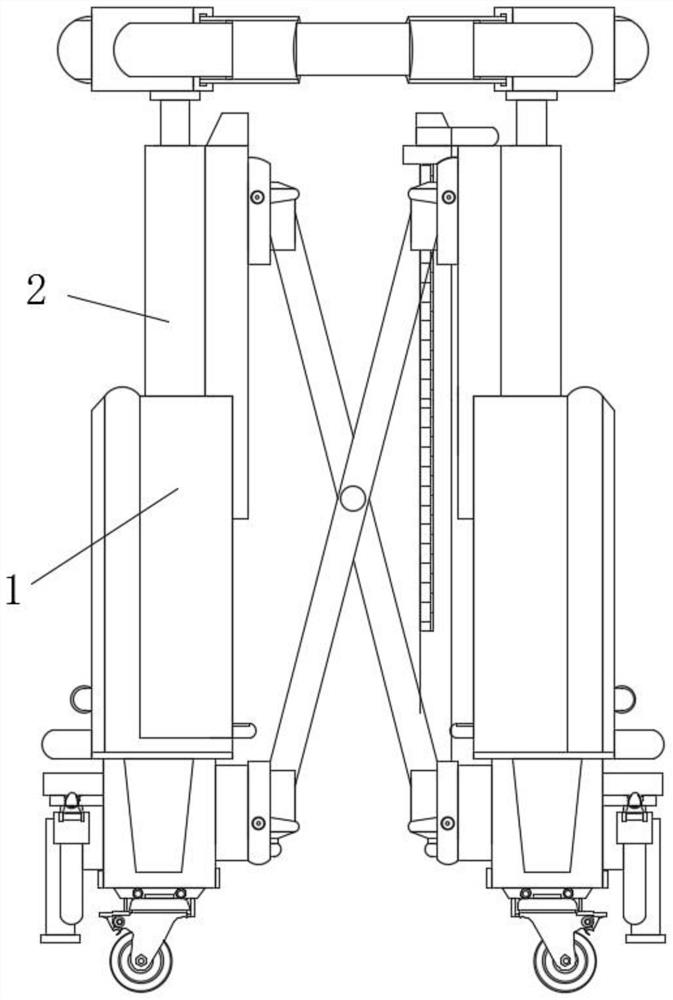

[0047] Example 2, such as Figure 1-4 As shown, after the scaffold is fully deployed, the hanging and fixing of the hook and the hanging ring can be cancelled. At this time, two groups of stepped seats 11 can be stepped on to drive the sliding sleeve 9 to descend along the outer guide around the sliding pole 10, so that the stepped seats 11 can touch the ground. Increase the fixed support points on the side of the scaffold, and facilitate the operator to step on the step seat 11 to climb the installation platform 3 and the step plate 8 to the top of the scaffold, so as to improve the flexibility and stability of the scaffold.

[0048] Working principle: When the scaffold is actually used and assembled, the two sets of C-shaped beam frames 1 are spliced together through the installation platform 3 and multiple sets of stepped plates 8 as the vertical beam support structure, and are divided into two groups corresponding to the two sides of the scaffold, and then the The convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com