A torque self-adaptive two-way non-stall screw motor valve

A screw-type, self-adaptive technology, applied in valve details, valve devices, mechanical equipment, etc., can solve problems such as failure of motor valve on-off valves, hidden safety hazards, and increased costs, so as to achieve safe and reliable valve control, prolong practical life, and extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

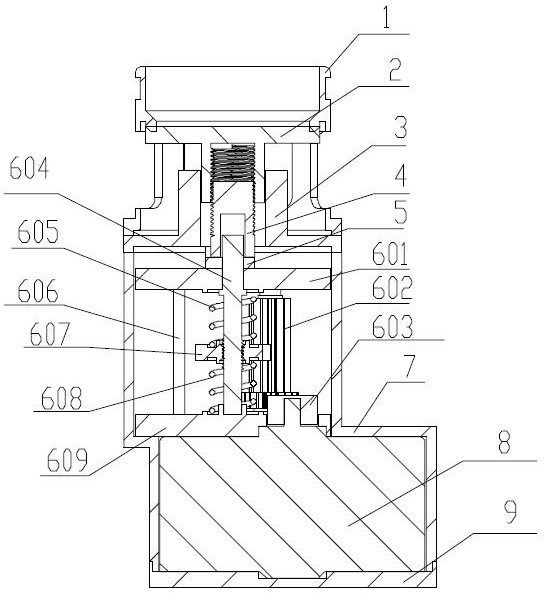

[0036] Below in conjunction with accompanying drawing, the present invention will be further described:

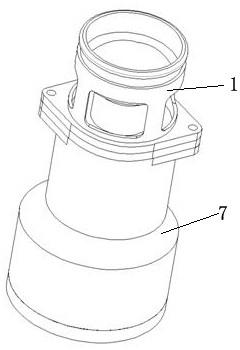

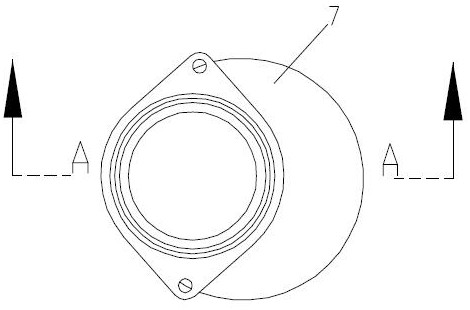

[0037] A torque self-adaptive two-way non-stall screw motor valve, including a valve body 1, a valve seal assembly, a reducer assembly 6 and a motor assembly that are mated and connected. The reducer assembly 6 includes an upper support plate 601, a lower support plate 609, and a motor assembly. Gear 603, duplex gear 602, transmission screw rod 604 and transmission gear 607, duplex gear 602 is arranged between upper support plate and lower support plate by fixed shaft 610, upper support plate and lower support plate are connected by pin 606, motor gear 603 is set on the output shaft of the motor and meshes with the large gear at the bottom of the double gear, the transmission gear 607 is set on the transmission screw 604 and meshes with the pinion at the top of the double gear, and the limit of the transmission screw 604 is set on the upper support plate and the lower Betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com