Total station reflector plate type steel beam deflection measuring method

A technology of deflection measurement and total station, which is applied in the direction of measuring devices and instruments, and can solve problems such as complicated installation and dismantling, and difficult erection of operating platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

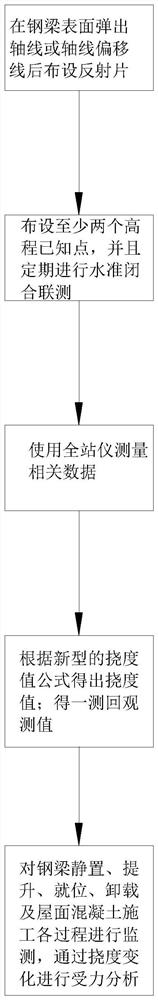

[0050] Combine Figure 1 to 3 A method for measuring the deflection of sheet steel beam reflector total station, includes the following steps comprising:

[0051] Step 1, after the ground assembly of the steel beam, the axis or axial offset line is pop-up on the surface of the steel beam, and reflecting the reflection sheet at both ends and across the steel beam;

[0052] Step ii, set at least two elevation known points under the bottom plate below the steel beam, regularly closing the high-pass known points, ensuring that the known point elevation value is accurate and reliable;

[0053] Step iii, using the whole station, the triangular elevation observation principle, according to the construction environment, the instrument is elected in the bottom plate, directly measured one of the known point elevations, and displays the high-pass counter instrument high, adjust the instrument to reset the station. This method avoids the error of the manual steel size to take high in the inst...

Embodiment 2

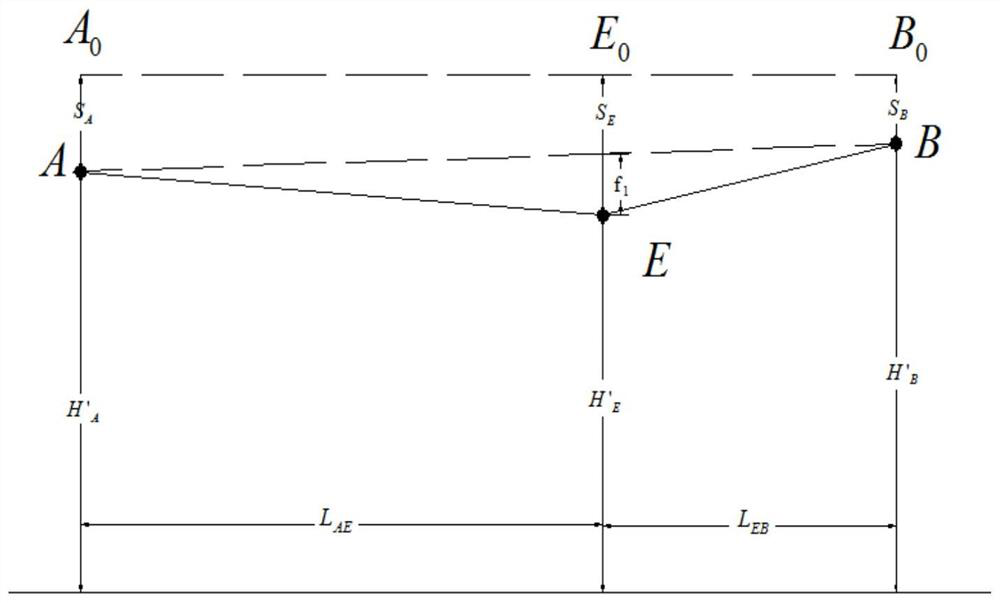

[0066] Combine Figure 1 to 3 , Vertical deflection at point E monitoring points in Step V f 1 The calculation method is as follows:

[0067] Depending on the triangle, the same principle is obtained:

[0068]

[0069] Organize:

[0070] (H ' B -H ' A ) × L BE = H ' B × (L) BE + L EA ) - (f 1 + H ' E × (L BE + L EA )

[0071]

[0072] final:

[0073]

[0074] Deflection Deflection variation value is a positive value, a negative value for the arch;

[0075] The E point is an arbitrary position of the axis, and if the E point is at the center of the axis, the degradation value derived is a deflection value in the axis, such as the E point at 1 / 4, the deflection value is 1 / 4 Deflection value. Beam eject surface offset axis or axis line apparatus using the ink cartridge, the pop-axis or axis line offset ink line; the reflecting sheet is a self-adhesive reflective sheet, the reflective sheet is provided with adhesive on the back structure.

Embodiment 3

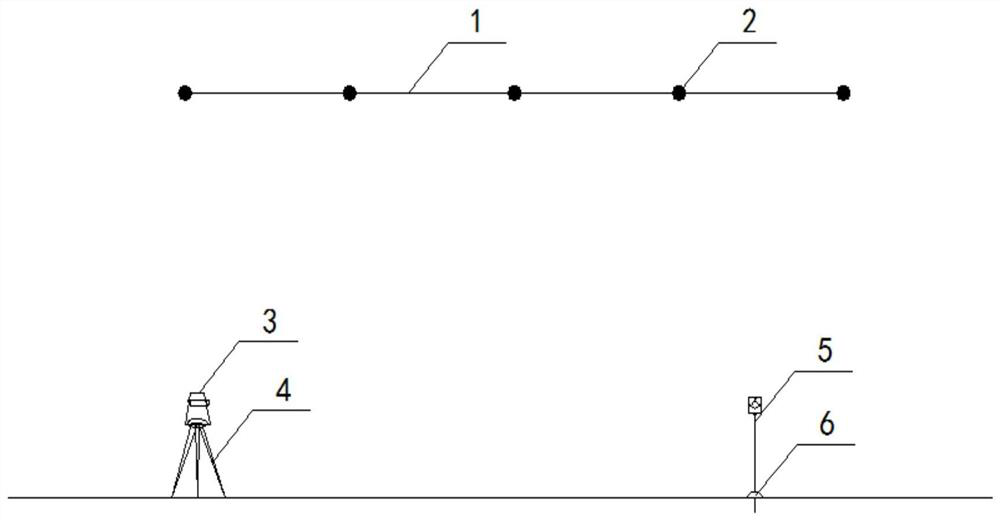

[0077] Combine Figure 1 to 3 A method for total station steel beam deflection measurement of the reflection sheet comprising triangular deflection of specifications similar geometric derivation formula, laid on a steel beam axis of the reflective sheet 12, known control points on the ground 6 after erecting prism 5, an arbitrary position on the ground 4 up a tripod 3 and the total station, by measuring a known control high elevation inverse calculation device 6, the height adjusting equipment redesign station, the total station is switched to the reflective sheet view mode , prism height is set to 0, and then directly measuring the relative coordinates and elevation of the reflection plate 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com