Motor loading test device and system

A test device and test system technology, applied in the direction of measuring device, engine test, machine/structural component test, etc., can solve the problem that the torque value cannot be automatically adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

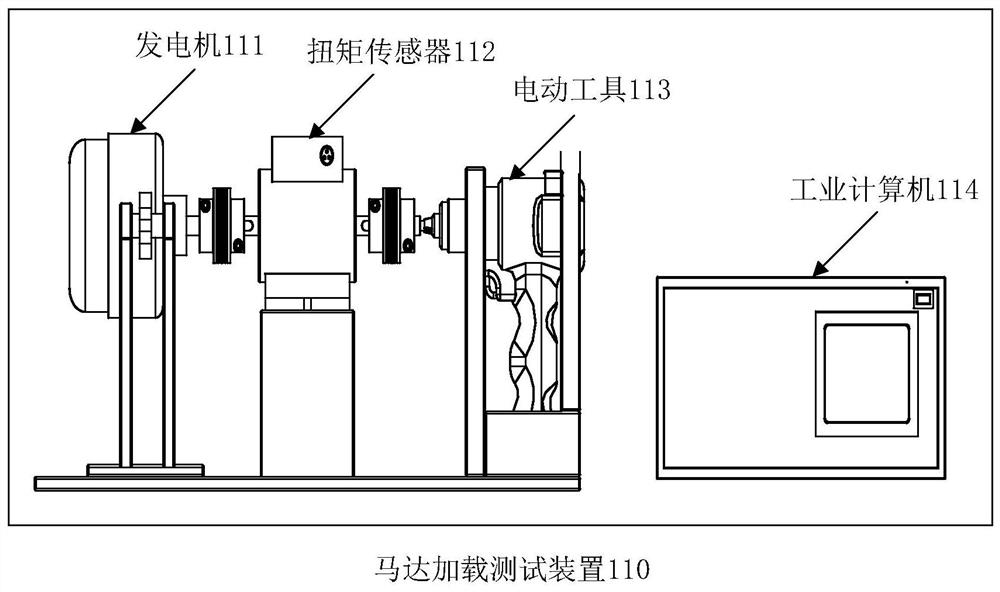

[0032] An embodiment of the present invention provides a motor loading test device, see figure 1 Shown is a structural schematic diagram of a motor loading test device, the motor loading test device 110 includes: a generator 111, a torque sensor 112, an electric tool 113 and an industrial computer 114; the generator 111, the torque sensor 112, and the electric tool 113 The shafts are connected sequentially, and the industrial computer 114 communicates with the electric tool 113;

[0033] The above-mentioned generator 111, torque sensor 112 and electric tool 113 can be fixed on the same straight line of the fixture by coupling fasteners, so that the generator 111, torque sensor 112 and electric tool 113 can rotate smoothly, and the generator 111, torque sensor 112 and The electric tools 113 can all be fixed on the testing machine base.

[0034] The above-mentioned torque sensor 112 is used to detect the test data of the electric tool 113 in the working process. The test data i...

Embodiment 2

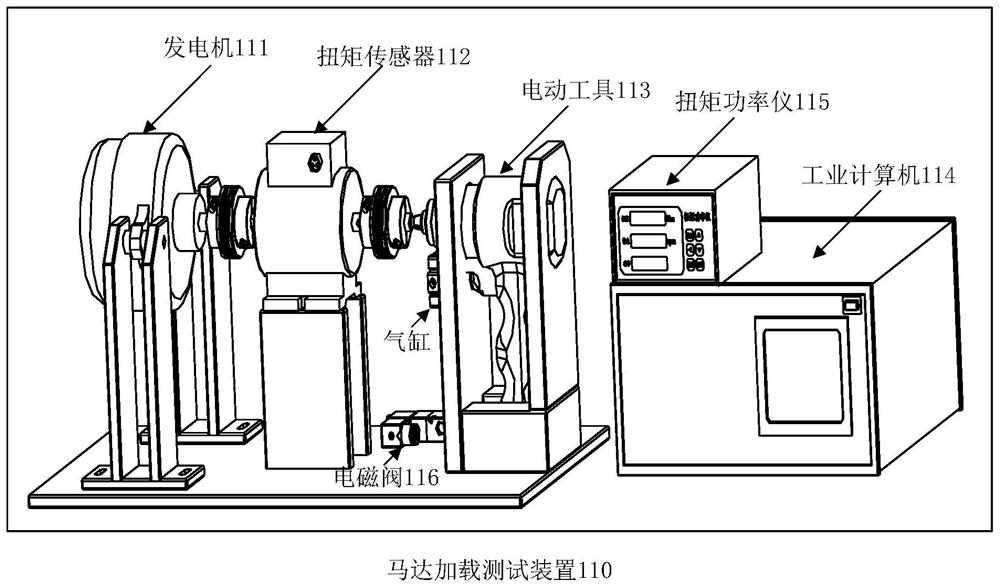

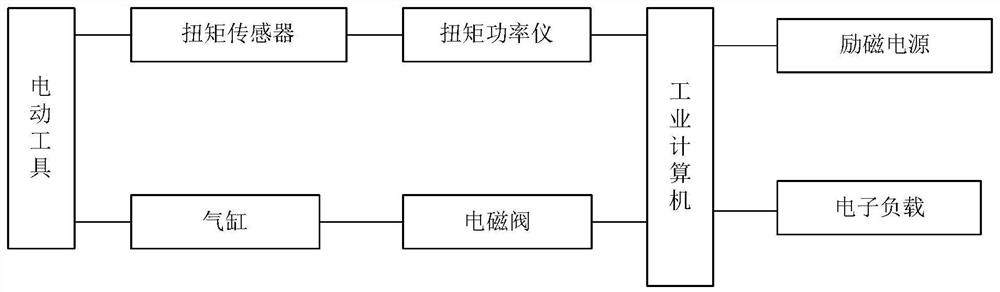

[0041] The embodiment of the present invention provides another motor loading test device, see figure 2 The structure schematic diagram of another kind of motor load test device shown, this motor load test device 110 also includes: torque power meter 115, excitation power supply (not shown in the figure), electronic load (not shown in the figure) and solenoid valve ;

[0042] The above-mentioned torque power meter 115 is connected with the torque sensor 112 for acquiring test data collected by the torque sensor 112 and displaying the test data. The industrial computer 114 is connected to the RS485 serial port of the torque power meter 115; the torque power meter 115 is also used to send test data to the industrial computer 114.

[0043] The above-mentioned excitation power supply is respectively connected with the generator 111 and the industrial computer 114; the USB port of the industrial computer 114 is connected with the RS232 serial port of the excitation power supply. ...

Embodiment 3

[0050] An embodiment of the present invention provides a motor loading test system, see Figure 4 A structural schematic diagram of a motor loading test system is shown, the motor loading test system 120 includes: an industrial camera 121, the above-mentioned motor loading test device 110 and a cloud server 122, and the industrial camera 121 and the cloud server 122 are connected in communication;

[0051] The industrial camera 121 is used to take the monitoring video of the motor loading test device 110 testing process, and the monitoring video is sent to the cloud server 122;

[0052] The cloud server 122 is used for receiving the monitoring video sent by the industrial camera 121 .

[0053] The aforementioned industrial camera 121 may be a charge coupled device camera, that is, a CCD (charge coupled device) camera.

[0054] The motor loading test system provided by the embodiment of the present invention has the same technical features as the motor loading test device prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com