Reflection structure, particle measuring device comprising same and detection method of particle measuring device

A reflective structure and measurement device technology, which is applied in the direction of measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of high processing complexity, difficult mask plate structure design, and inability to realize backscattered light detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

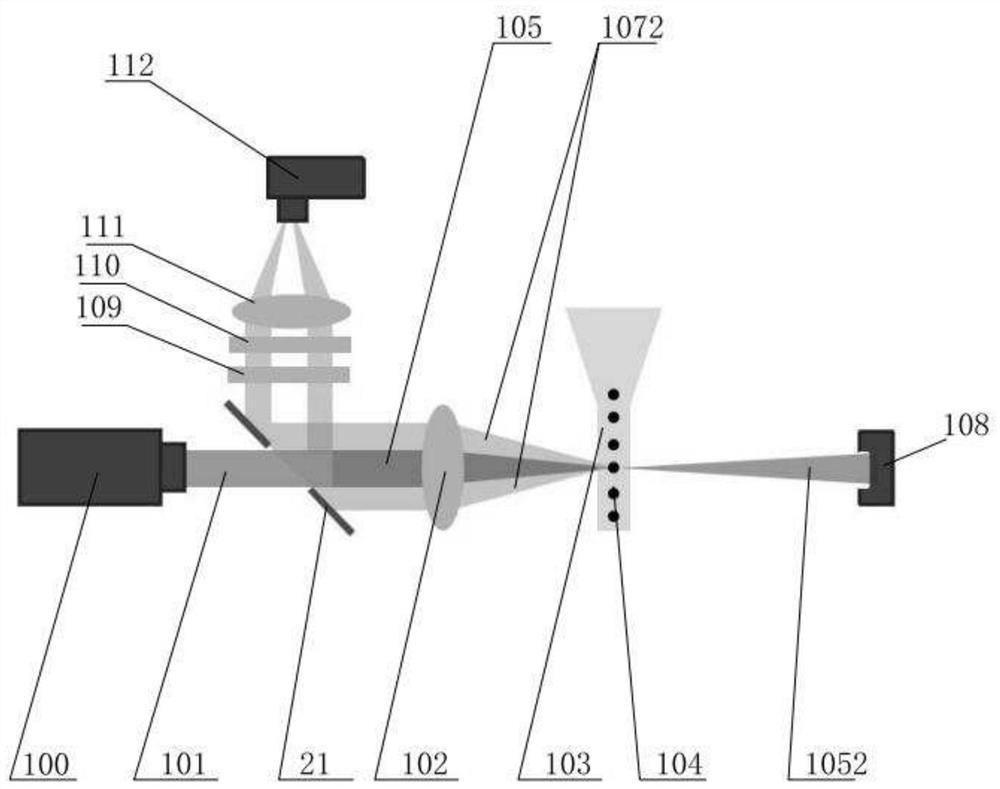

[0055] Please refer to figure 1, a particle measurement device, comprising a light source 100, a reflective structure 20, at least one first lens 102, a flow chamber 103, a detector 112 and a blocking element 108, wherein the light source 100 is used to emit an illumination beam; the first lens 102 is used to focus the illumination beam to the center of the flow chamber 103; the flow chamber 103 is used to make the liquid droplets containing particles sequentially irradiated by the illumination beam and generate direct light and at least one scattered light; the The reflective structure 20 is used to separate the direct light and at least one of the scattered light; the detector 112 is used to receive and detect at least one of the scattered light; the shielding element 108 is used to block and / or eliminate the direct light.

[0056] Specifically, please refer to figure 1 When the incident direction of the illumination light beam is the same as the outgoing direction of the ...

Embodiment 2

[0101] The structure and detection method of the second embodiment are mostly the same as those of the first embodiment, except that the backscattered light signal 1072 is used to characterize the number and size information of the particles. In the second embodiment, the propagation direction of the backscattered light signal 1072 is The propagation directions of the incident light beam 101 and the outgoing second outgoing direct light 1052 are opposite to each other, so mutual interference between the incident light beam 101 and the backscattered light signal 1072 needs to be avoided. Due to the different propagation directions, the reflective structure 20 is disposed between the flow chamber 103 and the light source 100 , and the reflective surface of the reflective structure 20 may face the propagation direction of the backscattered light signal 1072 .

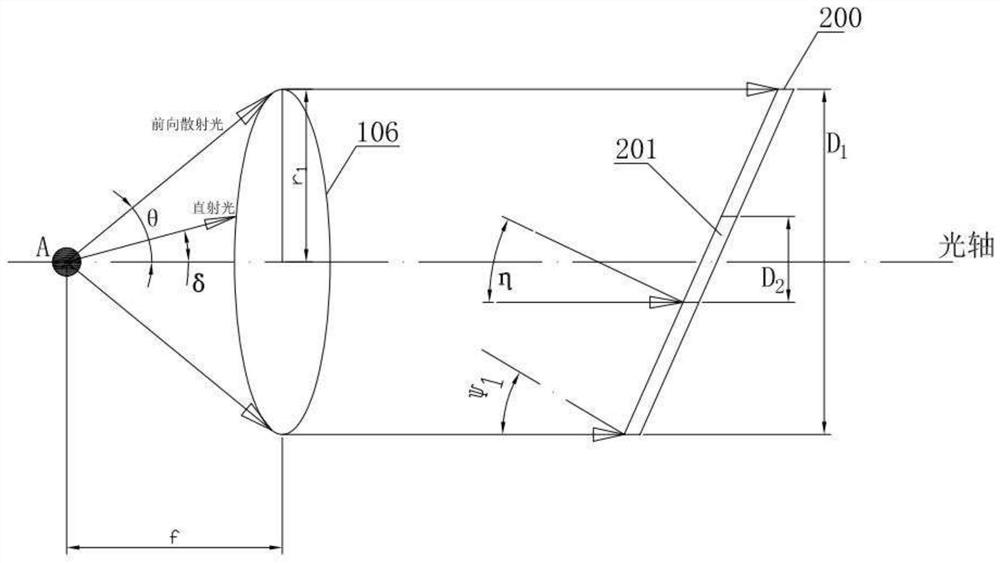

[0102] Further, please continue to refer to figure 2 with Figure 4 , in the particle detection device described in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com