Concrete filled steel tube void detection system and method

A technology of steel pipe concrete and detection methods, which is applied in the field of thermal simulation and prefabricated buildings, and can solve problems such as small detection depth and inability to quantitatively detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

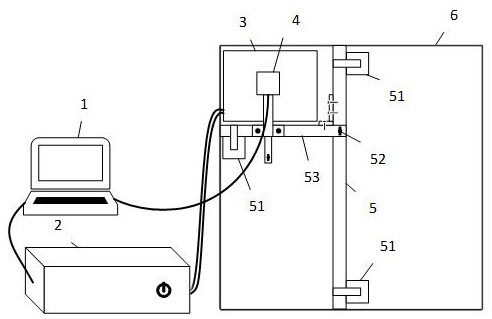

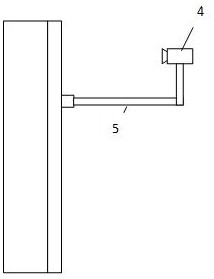

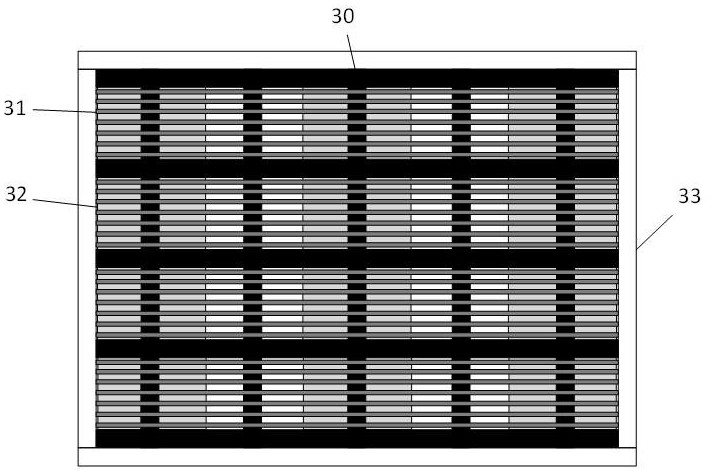

[0041] like Figure 1a and Figure 1b As shown, a concrete-filled steel tube emptying detection system includes an infrared thermal imager 4 for collecting temperature data on the detection surface; it also includes a power supply 2 and a reel 3 for induction heating, and a bracket 5 for auxiliary detection , the thermal imager 4 is fixed on the support 5 and is located directly in front of the current detection surface; the sliding knob 52 of the support 5 can move the cross bar 53 up and down, so as to detect multiple areas at one time; the support 5 is fixed with 3 magnetic bases 51. Ensure that no jitter occurs during the detection. The wire reel 3 is composed of a ferrite core 30, a high-frequency excitation wire 31, a wire slot 32, and an aluminum alloy shell 33, see figure 2, when the wire coil is energized, the steel pipe concrete 6 is heated in the form of eddy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com