Method, system, device and storage medium for determining camera intrinsic parameter error

A camera and error technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as unsuitable and fast screening of unqualified cameras, and achieve the effect of fast processing speed and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

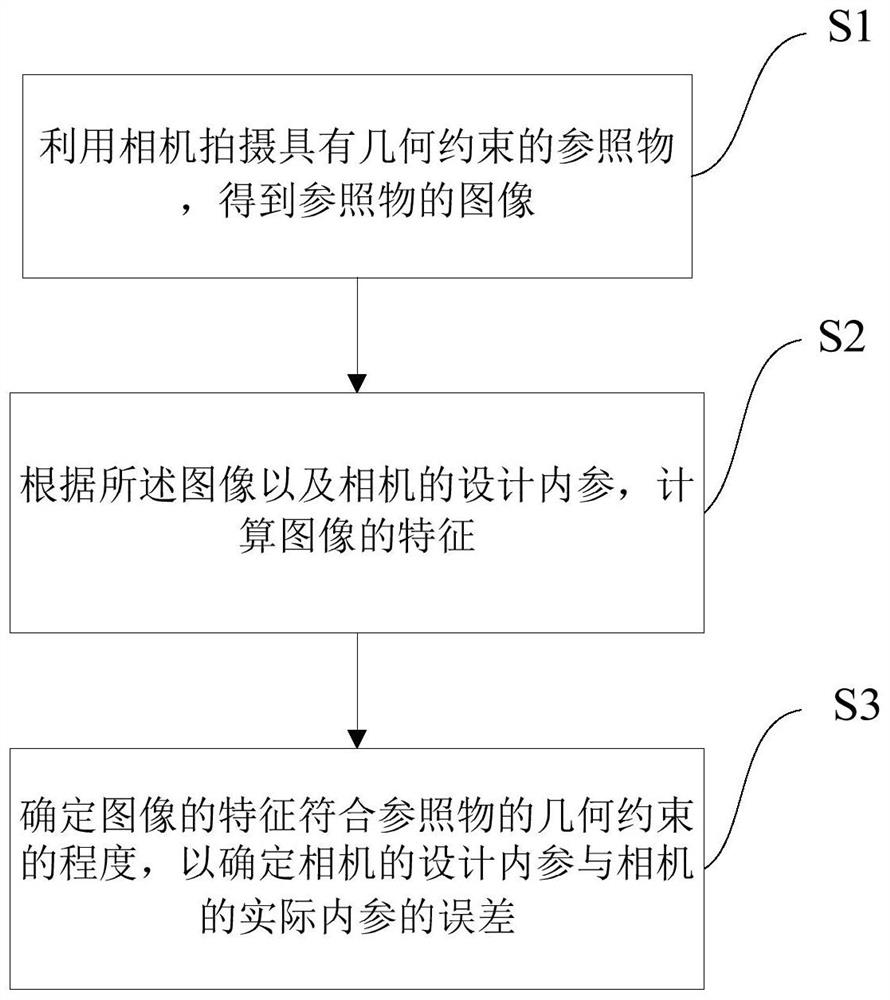

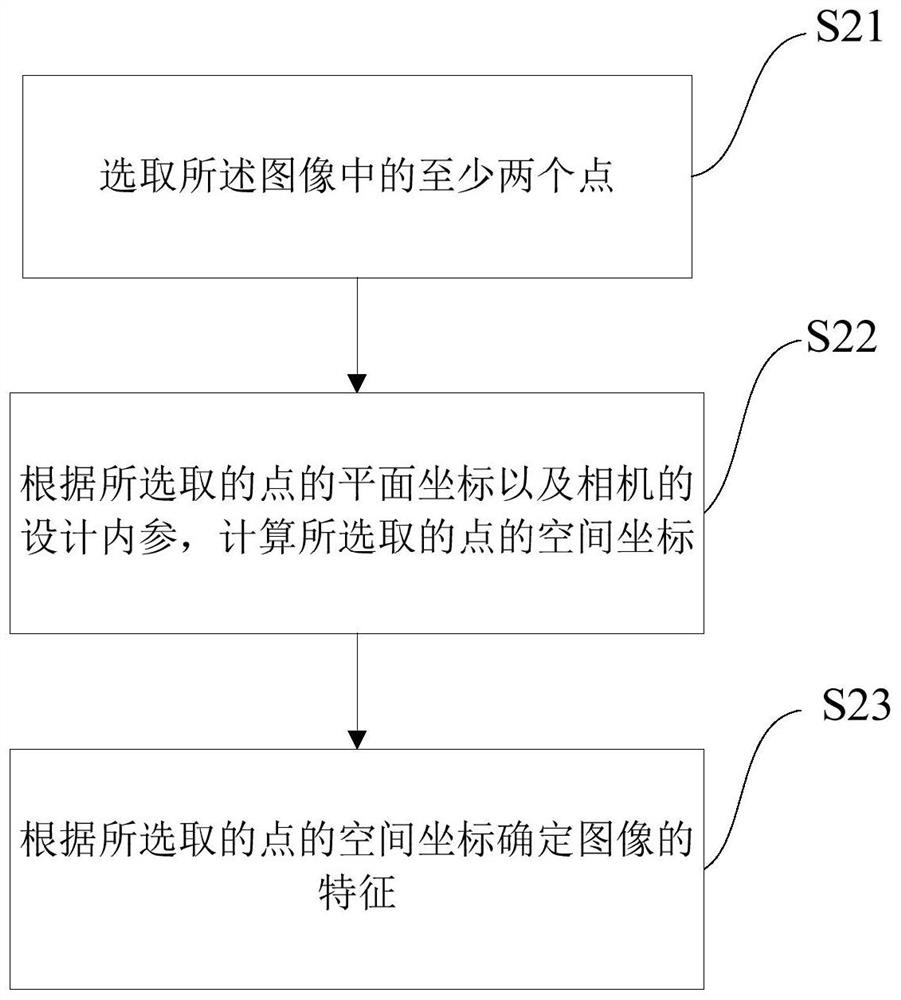

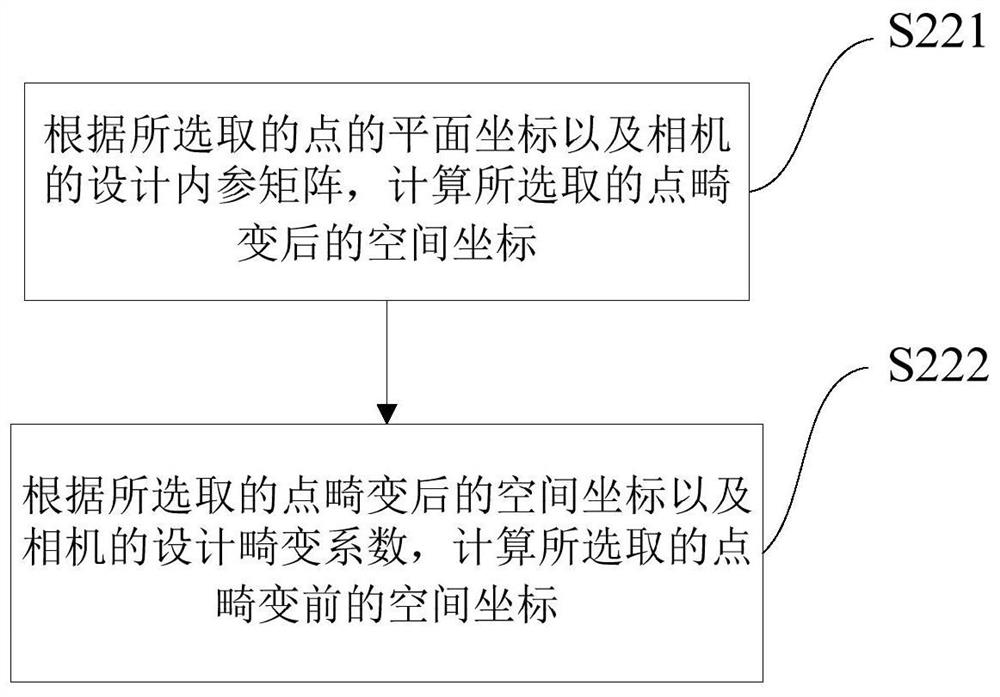

Method used

Image

Examples

Embodiment 2

[0088] Based on the same idea as the previous embodiment, this embodiment provides a system for determining camera intrinsic parameter errors, which is used for screening cameras with problems. Problematic cameras refer to cameras with large differences in internal parameters after the assembly is completed and the AA is actually involved in the design. The camera generally corrects the captured image according to its design internal parameters. If the camera has a large difference between the actual internal parameters and the design internal parameters, the image captured by the camera has a high degree of distortion and does not meet the requirements for use.

[0089] like Figure 8 As shown, the system for determining the camera intrinsic parameter error includes:

[0090] An image acquisition module 100, configured to acquire an image of a reference object with geometric constraints captured by a camera;

[0091] The feature calculation module 200 is used to calculate t...

Embodiment 3

[0109] Based on the same idea as the previous embodiment, this embodiment also provides a computer device, including a memory and a processor, where the memory stores a computer program, and the processor implements the determination in the first embodiment when executing the computer program The method for camera intrinsic parameter error has corresponding functions and beneficial effects.

Embodiment 4

[0111] Based on the same idea as the previous embodiment, the present embodiment also provides a computer-readable storage medium on which a computer program is stored, and when the computer program is executed by a processor, implements the method for determining the camera internal parameter error described in the first embodiment , with corresponding functions and beneficial effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com