A screening and grading equipment for rice processing

A technology of rice processing and equipment, which is applied in sieving, solid separation, and separation of solids from solids by air flow. Uneven and other problems, to achieve the effect of convenient control, reduce energy consumption, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

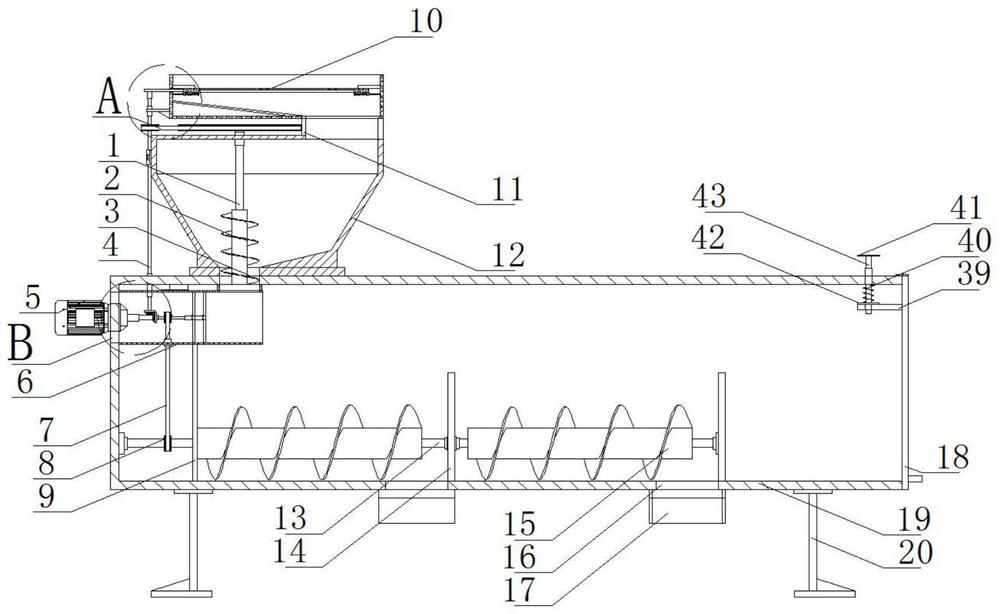

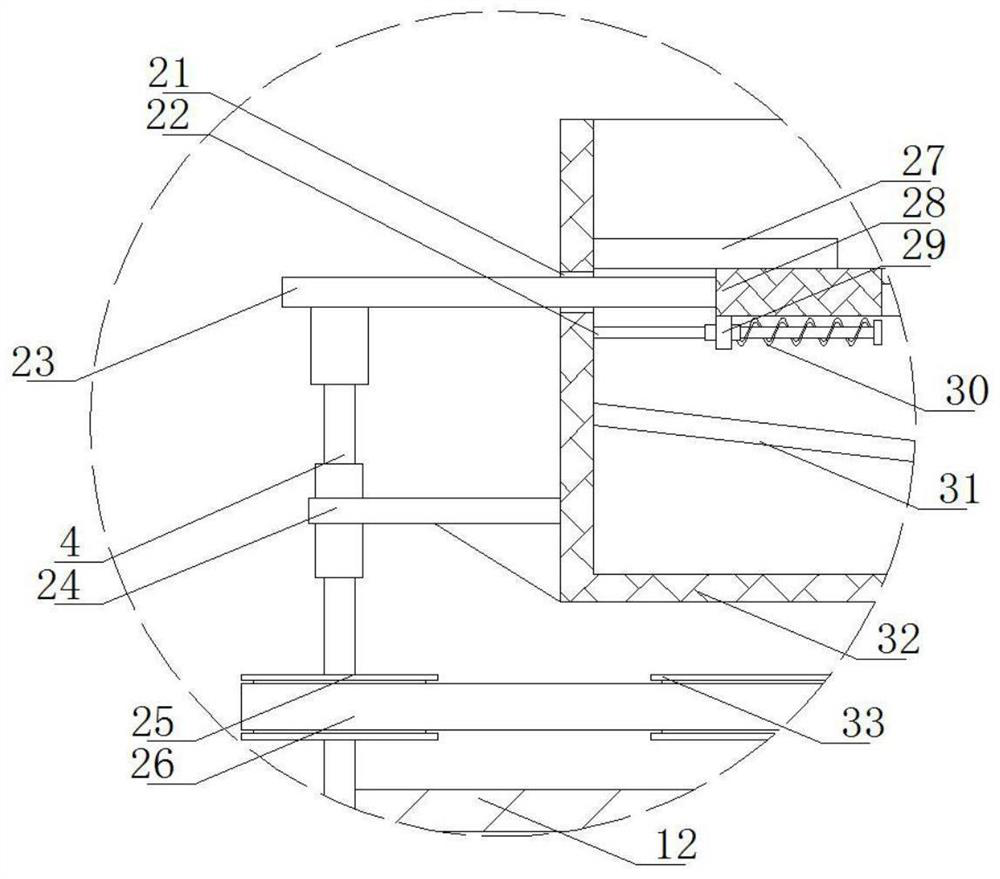

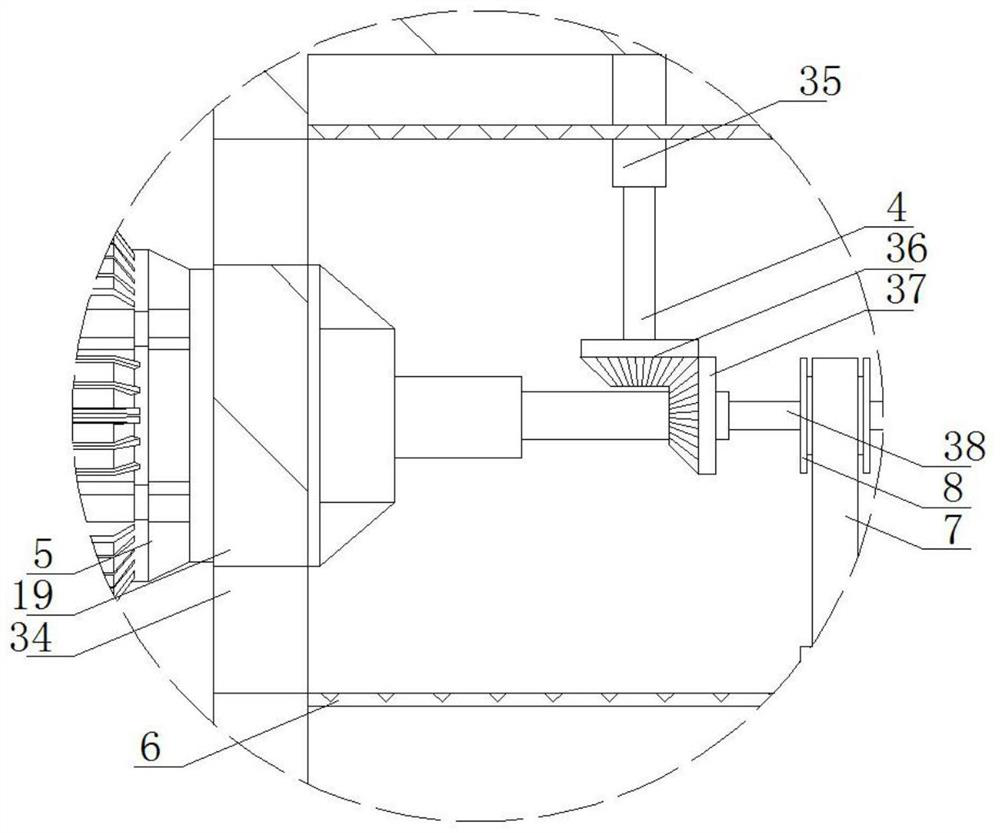

[0035] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

[0036] refer to Figure 1-9 , a screening and grading equipment for rice processing, including a winnowing box 19, the winnowing box 19 is made of stainless steel, and its upper end is rectangular, and its lower end is semicircular. The rice grains or powders are piled up at the bottom of the winnowing box 19, which is convenient for transportation, so that it is convenient for the staff to collect, and it is convenient for subsequent processing or storage. The lower end of the winnowing box 19 is fixed on both sides with brackets 20, which are welded by welding. It is fixed on both sides of the lower end of the air selection box 19 to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com