An electric vehicle wiring harness automatic pipe threading equipment

An automatic threading, electric vehicle technology, applied in cable laying equipment, mechanical equipment, engine components, etc., can solve the problems of reducing the efficiency of wire harness threading, inability to align the center line, and failure of harness threading, etc. Pipe efficiency, reduce pipe penetration errors, and reduce the effect of wire harness pipe penetration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

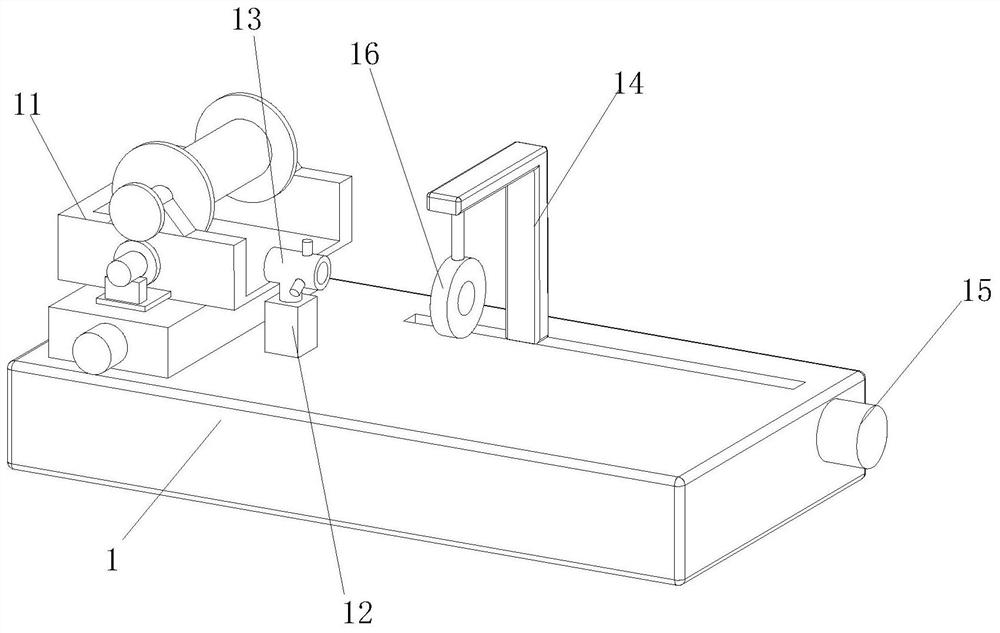

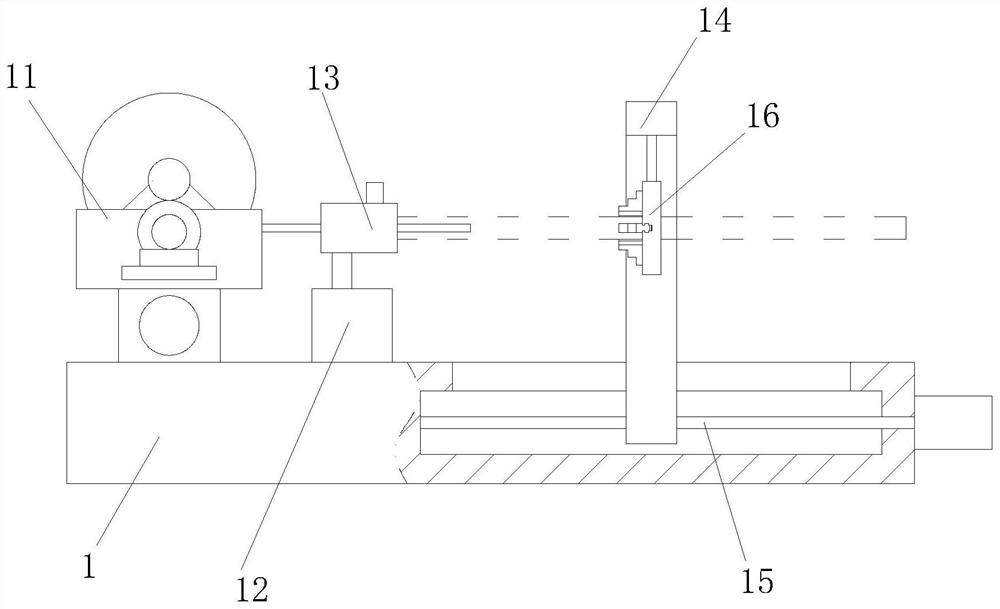

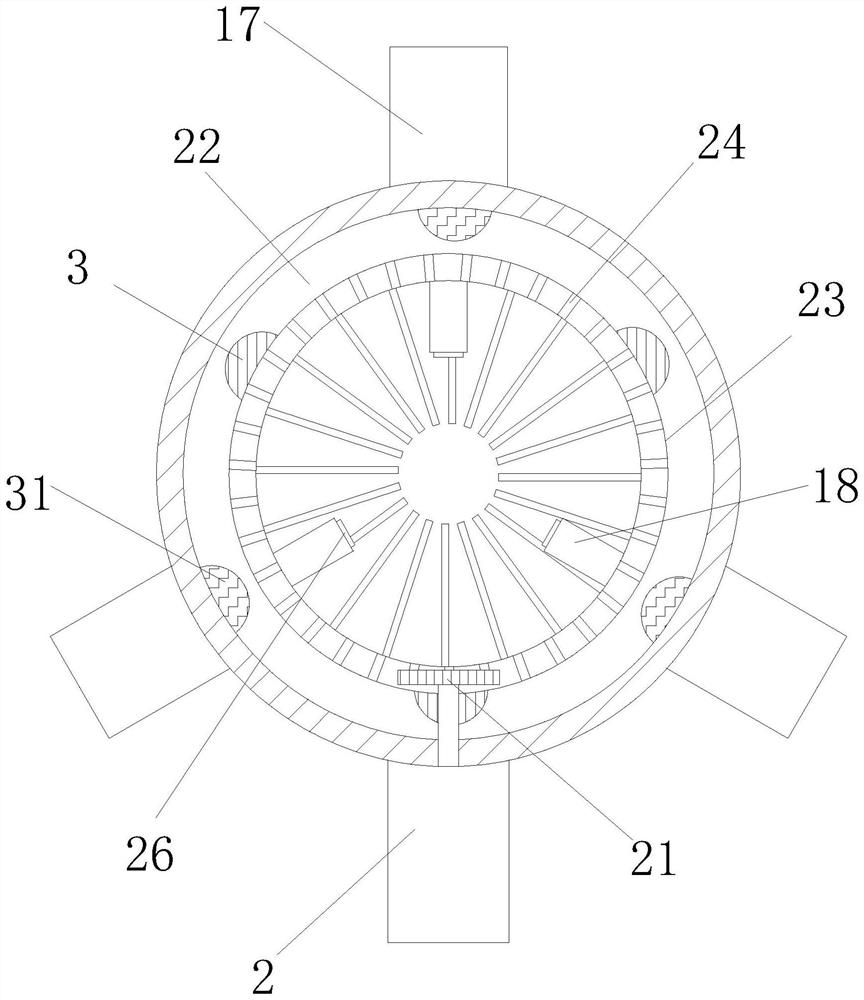

[0032] Such as Figure 1 to 6 As shown, an electric vehicle wire beam automatic tube device according to the present invention includes a table 1; the top end of the table 1 is provided with an amplifier unit 11 and a fixing seat 12; the fixing seat 12 is located at a disposing unit. 11 placement side; the top end of the fixing seat 12 is provided with a wire barrel 13 by a fixed column; the working unit 1 is connected to the L-shaped plate 14 through the moving unit 15, and the L-shaped plate 14 is away from the end portion of the workbench 1. The bottom end is solid to have a trip chuck 16 by a fixed column; the centerline of the trunculating chuck 16 and the centerline of the wire barrel 13 is coincidentically; and there are three hydraulic cylinders 17, and there are three hydraulic cylinders 17, and hydraulic cylinders. 17 The hydraulic rod 18 set in the lead barrel 13, points to the center point of the lead barrel 13; when operating, in the prior art, the discharge unit 11 pu...

Embodiment 2

[0041] See Figure 7 - Figure 8 As shown, Comparative Example 1, as another embodiment of the present invention, the first arc-shaped block 3 is hollow, and the first arc-shaped block 3 is opened between the outer wall of the annular plate 23. Cavity 6; the first ring groove 22 slot bottom is fixed to a magnetic block 63 relative to the first arc block 3; the inner wall of the first cavity 6 is fixed to the first magnetic ball 62 through the elastic rope 61 The first magnetic ball 62 and the magnetic block 63 are mutually rejected; when the annular plate 23 is rotated at the first annular groove 22, the first magnetic ball 62 moves outward in the spring elastic force in the first arc. When the block 3 and the magnetic block 63 are approached, the first magnetic ball 62 and the magnetic block 63 are urgently pushed into the inner wall of the first cavity 6, and the outer side wall of the vibration ring plate 23 is driven. The plate 23 is clearly sweeping brush, which not only achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com