Inverted conveying device and method for processing thin-film capacitor

A technology of thin film capacitors and conveying devices, which is applied in the direction of thin film/thick film capacitors, terminal application devices, fixed capacitor parts, etc., can solve the problems of difficulty in heat shrinkable tubes and difficult alignment of heat shrinkable tubes, and achieve improved Handling efficiency, light structure, and the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

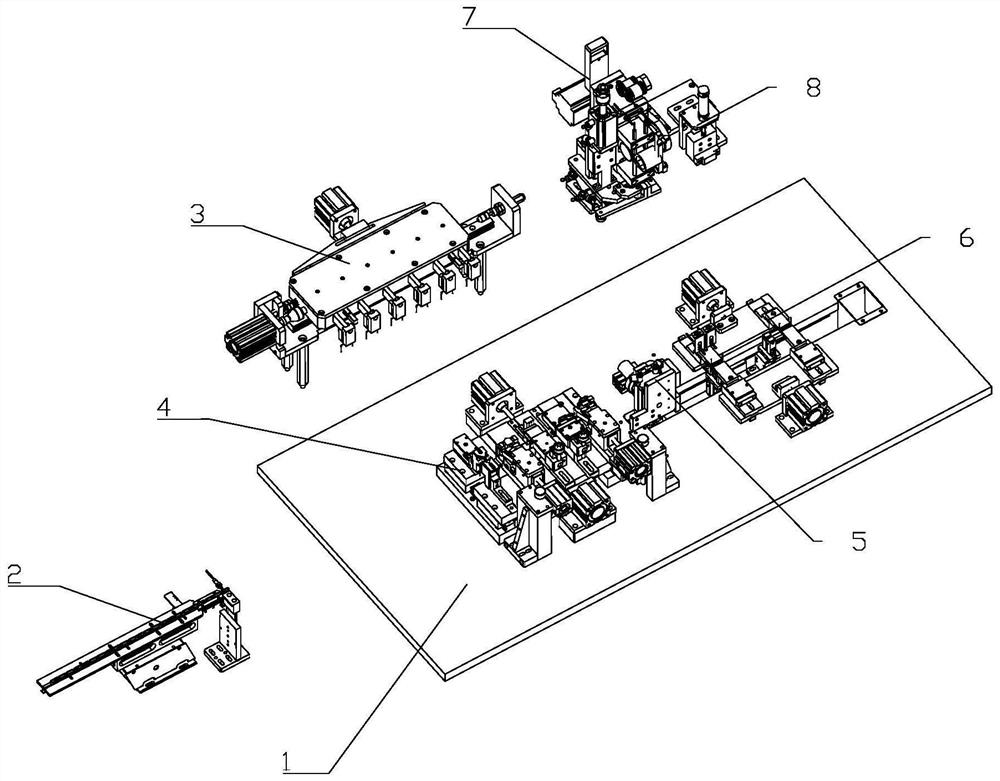

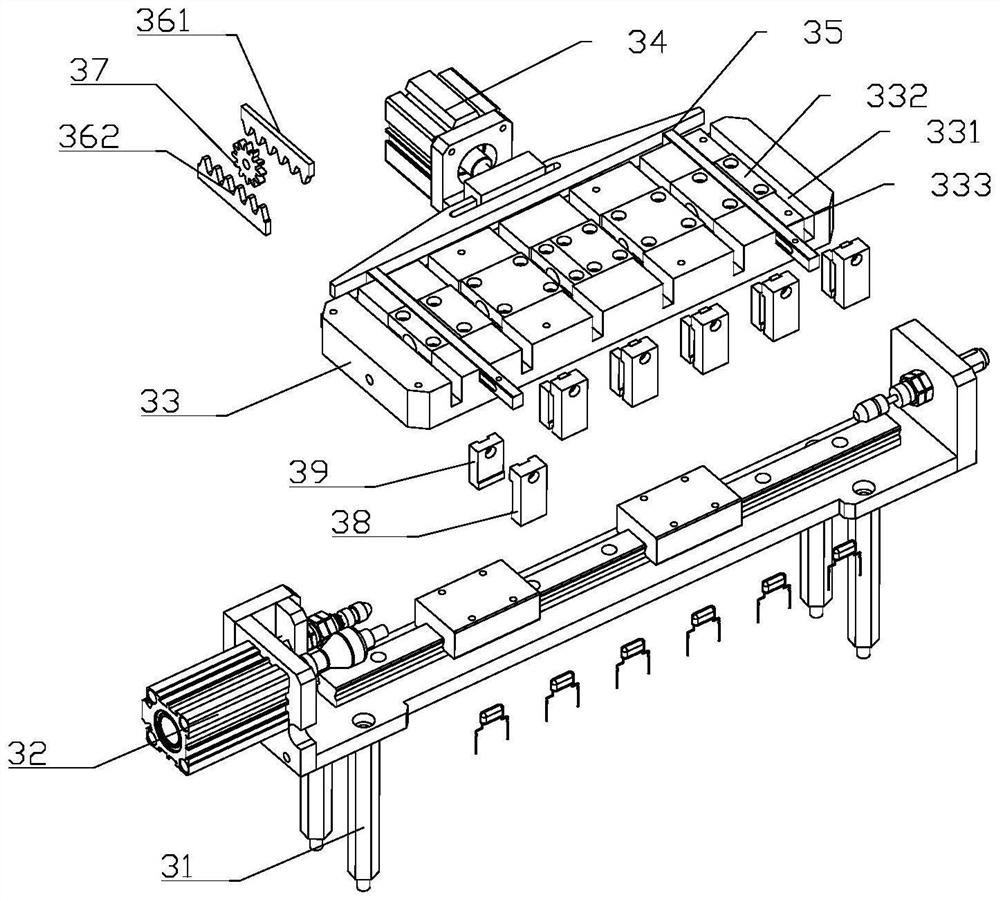

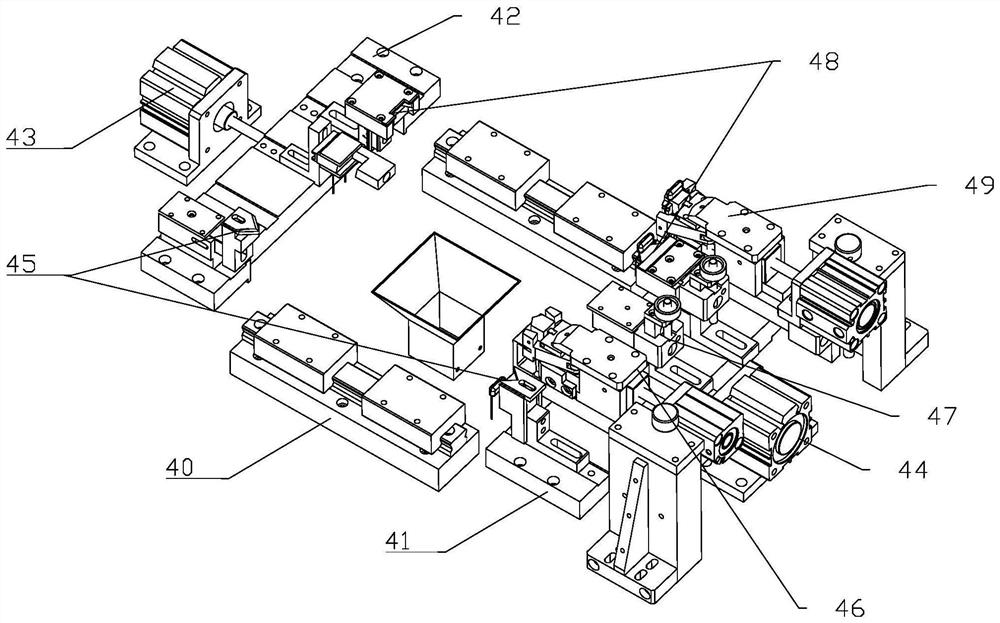

[0031] Such as figure 1 As shown, a film capacitor production equipment includes a frame 1 and a feeding and conveying device 2 installed on the frame 1, a clamping and transferring device 3, a multifunctional forming device 4, a rotating material turning device 5, and a flip-chip conveying device. Device 6, pipe threading device 7 and pipe pressing device 8; feeding and conveying device 2 is connected with clamping and transporting device 3, and multi-functional forming device 4 is located below clamping and transporting device 3; described rotating material turning device 5 The multifunctional molding device 4 is connected with the flip-chip conveying device 6; the pipe threading device 7 and the tube pressing device 8 are located above the flip-chip conveying device 6, and the frame 1 is also provided with a blanking barrel, and the falling The material barrel is connected with the discharge side of the inverted conveying device 6, and the frame 1 is also provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com