Polyethylene having high degree of cross-linking, and cross-linked polyethylene pipe comprising same

A polyethylene, density technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problem of reduced cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

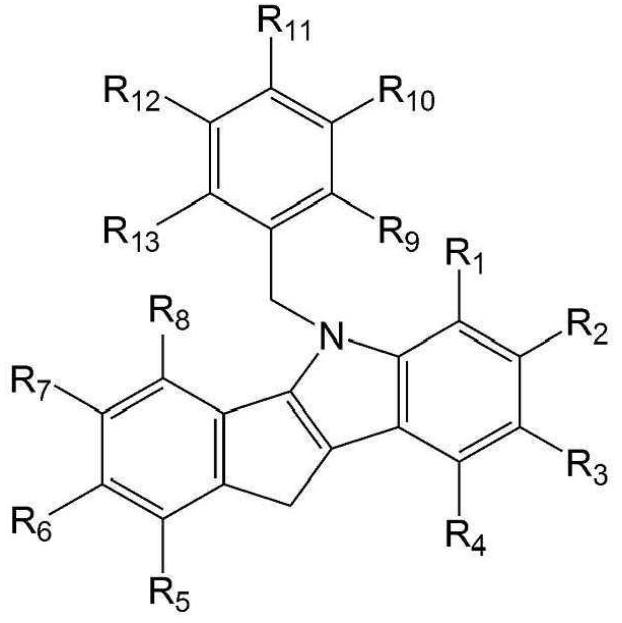

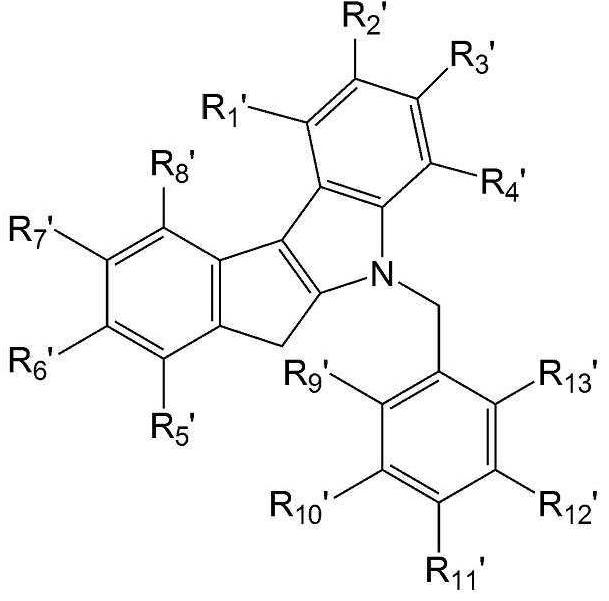

[0157] 1-1 Preparation of Ligand Compounds

[0158] Dissolve 2.9 g (7.4 mmol) of 8-methyl-5-(2-(trifluoromethyl)benzyl)-5,10-dihydroindeno[1,2-b]indole in 100 mL of hexane Alkanes and 2 mL (16.8 mmol) of MTBE (methyl tert-butyl ether), and in a dry ice / acetone bath, 3.2 mL (8.1 mmol) of 2.5 M n-BuLi hexane solution was added dropwise, and then the mixture was stirred at room temperature overnight. In another 250 mL Schlenk flask, 2 g (7.4 mmol) of (6-tert-butoxyhexyl)dichloro(methyl)silane was dissolved in 50 mL of hexane, which was then added dropwise in a dry ice / acetone bath, and A lithiated slurry of 8-methyl-5-(2-(trifluoromethyl)benzyl)-5,10-dihydroindeno[1,2-b]indole was added dropwise via cannula. After the injection was complete, the mixture was slowly warmed to room temperature and then stirred overnight at room temperature. Meanwhile, 1.2 g (7.4 mmol) of fluorene was also dissolved in 100 mL of THF, and in a dry ice / acetone bath, 3.2 mL (8.1 mmol) of 2.5 M n-Bu...

preparation Embodiment 1

[0176] 5.0 kg of toluene solution was added into a 20 L autoclave, and the temperature of the reactor was kept at 40 °C. 1000 g of silica (manufactured by Grace Davison, SP 948) was dehydrated by applying a vacuum at a temperature of 600° C. for 12 hours, and then added to the reactor to sufficiently disperse the silica. Then 495 g of the first metallocene compound of Synthesis Example 1 was dissolved in toluene, and then added thereto. The mixture was reacted at 40° C. for 2 hours while stirring at 200 rpm. Stirring was then stopped, and the reaction solution was left to stand for 30 minutes and decanted.

[0177] 2.5 kg of toluene was charged into the reactor, 9.4 kg of a 10% by weight methylaluminoxane (MAO) / toluene solution was added thereto, and the mixture was stirred at 200 rpm at 40° C. for 12 hours. After the reaction, stirring was stopped, and the reaction solution was left to stand for 30 minutes and decanted. 3.0 kg of toluene was added thereto and stirred for 1...

preparation Embodiment 2

[0182] A hybrid supported catalyst was prepared in the same manner as in Preparation Example 1, except that 476 g of the first metallocene compound of Synthesis Example 1 was added, and 34 g of the second metallocene compound of Synthesis Example 2 was added. In the prepared hybrid supported catalyst, the molar ratio between the first metallocene compound and the second metallocene compound was 8:1.

[0183]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com