Coating material for wear-resistant teaching blackboards, and preparation method of coating material

A technology of coating materials and blackboards, applied in coatings, polyurea/polyurethane coatings, reusable writing boards, etc., can solve the problem of affecting polymerization reactions, large volume shrinkage affecting adhesion, and affecting the overall performance of light-curing materials, etc. problems, achieve the effects of reducing viscosity and surface tension, avoiding oxygen inhibition phenomenon, and fast curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

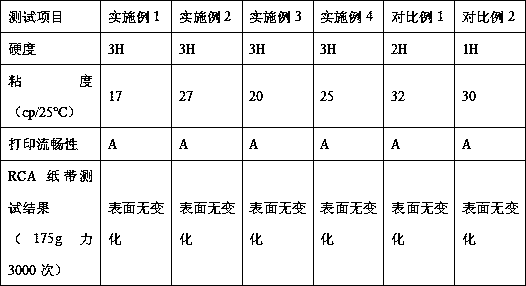

Examples

Embodiment 1~4

[0030] Embodiments 1 to 4: A coating material for a wear-resistant teaching blackboard, the coating material for a wear-resistant teaching blackboard consists of the following components in parts by weight, as shown in Table 1:

[0031] Table 1

[0032] components

Example 1

Example 2

Example 3

Example 4

Aliphatic polyurethane triacrylate

20 copies

24 copies

18 copies

27 copies

40 copies

48 copies

36 copies

35 copies

Ethylene glycol diglycidyl ether

11 copies

13 copies

12 copies

12 copies

Alkyl modified polysiloxane

3 copies

4.5 servings

2.5 servings

3.5 servings

2 copies

1.3 parts

2.3 servings

1.5 servings

Butyl hydroxycresyl

1.0 copies

1.2 parts

0.8 parts

0.9 parts

Organic thermosetting polymethylurea resin

3 copies

2 copies

4 parts

2 copies

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com