Ways to Digitally Enhance Printed Matter Surfaces

A printed matter and digital technology, applied in the field of digital enhancement on the surface of printed matter, can solve the problems of expensive equipment, high toxicity, damage to the nozzle, etc., to achieve a wide range of process applications, improve curing efficiency, and prevent the surface from sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] Embodiment Ⅰ surface hot stamping

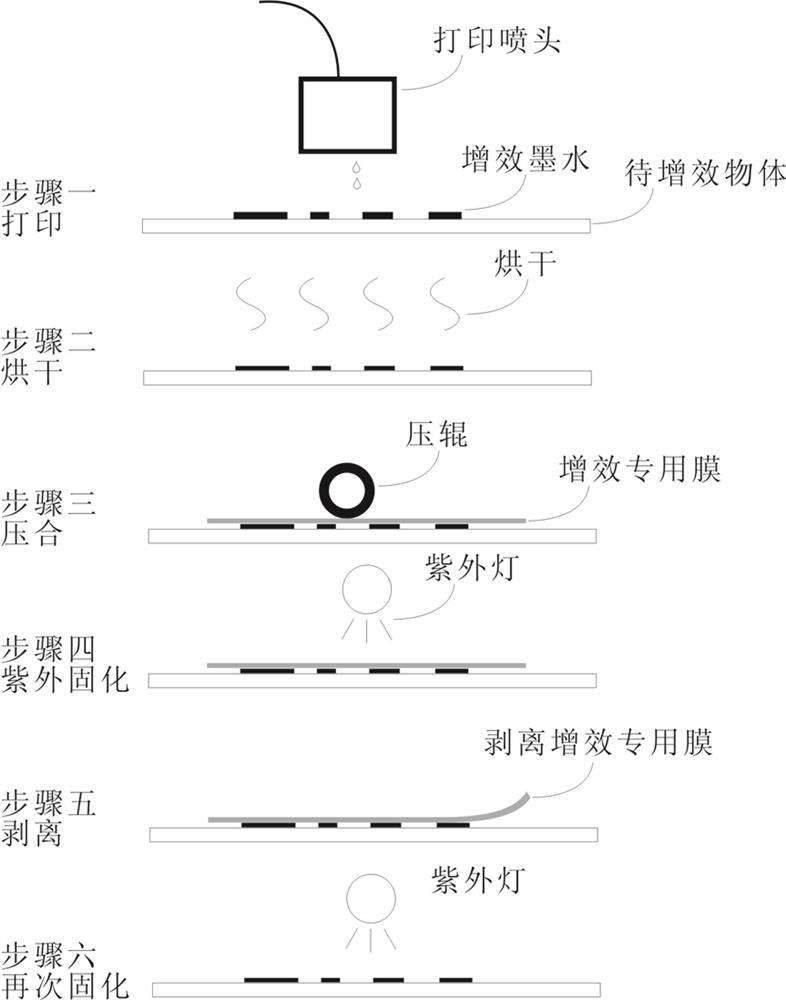

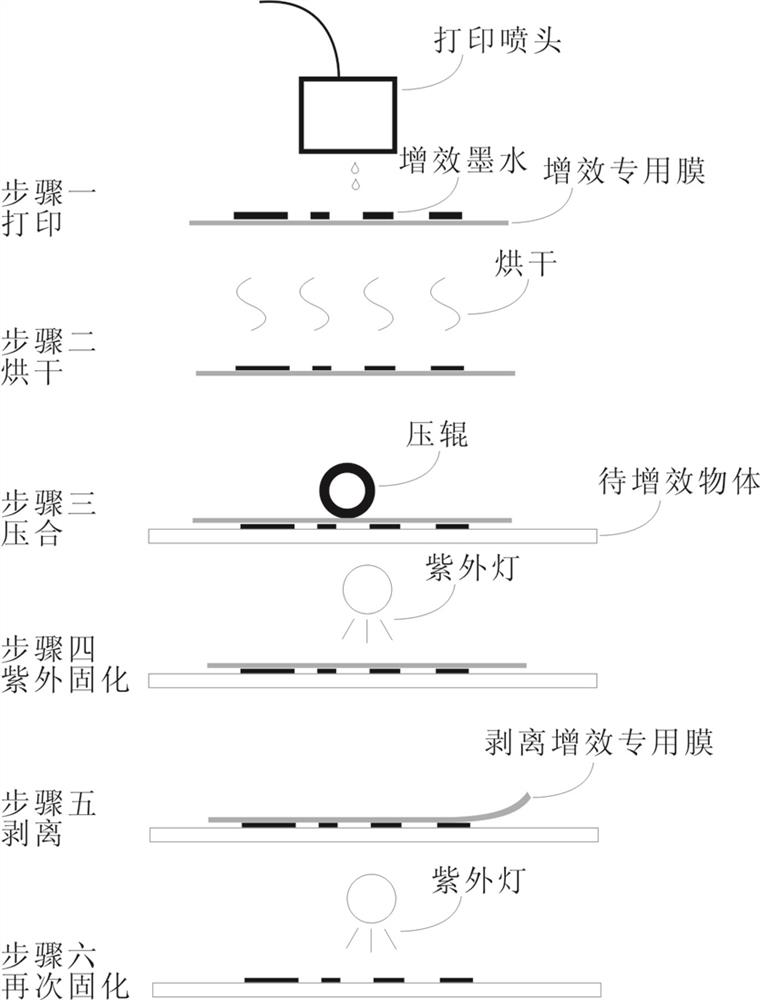

[0083] Figure 5 The hot stamping process of the paper surface in Example I is shown.

[0084] Such as Figure 5 As shown, the special film for synergistic use is a 6-inch single-sheet special anodized aluminum for cold stamping (customized), and its structure is as follows: PET layer, release layer, vacuum aluminum layer, and protective layer, of which the thickness of the PET layer is 0.15mm , the anodized aluminum can be directly printed on the machine; use the Epson R330 printer, which is a 6-color piezoelectric inkjet printer, and fill the yellow, magenta, cyan, light pin, and light cyan ink cartridges with synergistic ink (customized), black The ink cartridge is filled with original black ink; the original is made in Coreldraw software, where the hot stamping pattern is filled with red (C, M, Y=100), the positioning line is set to black, and the original is printed on the surface of the special synergistic film through the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com