A kind of high heat resistance flame retardant antistatic pc/abs alloy material and preparation method thereof

A flame retardant antistatic, alloy material technology, applied in the field of alloy materials, can solve problems such as abnormal operation of integrated circuit chips, mechanical and heat resistance effects, loss of antistatic effect, etc., to achieve good appearance, flame retardancy and mechanical properties The effect of small performance and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

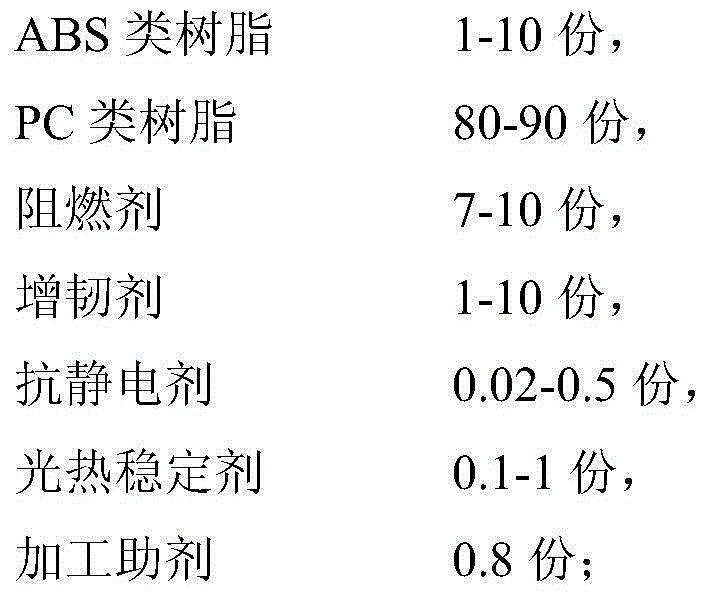

Method used

Image

Examples

Embodiment 1

[0041] With 1 part of ABS Daqing 750, 90 parts of PCIR2200, 7 parts of flame retardant FR-245, 0.02 part of multi-walled carbon nanotubes, 2 parts of MBS toughening agent, 0.3 part of light and heat stabilizer (1076:168=1:2 ) and 0.8 parts of processing aids (0.5 parts of EBS and 0.3 parts of PTFE-A3800) were uniformly mixed by high-speed stirring, and the above mixture was sent into a twin-screw extruder, and fully melted and compounded under the conveying and shearing action of the screw. , and then extruded through the machine head, drawn, cooled, pelletized, and finally packed.

[0042] The screw temperature of each section of the twin-screw extruder is controlled between 230-250°C, and the screw speed is 400 rpm.

[0043] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0045] With 5 parts of ABS Daqing 750, 85 parts of PCIR2200, 8 parts of flame retardant FR-245, 0.1 part of multi-walled carbon nanotubes, 8 parts of MBS toughening agent, 0.3 part of light and heat stabilizer (1076:168=1:2 ) and 0.8 parts of processing aids (0.5 parts of EBS and 0.3 parts of PTFE-A3800) were uniformly mixed by high-speed stirring, and the above mixture was sent into a twin-screw extruder, and fully melted and compounded under the conveying and shearing action of the screw. , and then extruded through the machine head, drawn, cooled, pelletized, and finally packed.

[0046] The screw temperature of each section of the twin-screw extruder is controlled between 230-250°C, and the screw speed is 400 rpm.

[0047] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 3

[0049] With 10 parts of ABS Daqing 750, 80 parts of PCIR2200, 9 parts of flame retardant FR-245, 0.5 part of multi-walled carbon nanotubes, 2 parts of MBS toughening agent, 0.3 part of light and heat stabilizer (1076:168=1:2 ) and 0.8 parts of processing aids (0.5 parts of EBS and 0.3 parts of PTFE-A3800) were uniformly mixed by high-speed stirring, and the above mixture was sent into a twin-screw extruder, and fully melted and compounded under the conveying and shearing action of the screw. , and then extruded through the machine head, drawn, cooled, pelletized, and finally packed.

[0050] The screw temperature of each section of the twin-screw extruder is controlled between 230-250°C, and the screw speed is 400 rpm.

[0051] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

[0052] Table 2

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com