Substrate treatment method and substrate treatment device

A substrate processing method and substrate technology, which can be used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as poor etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

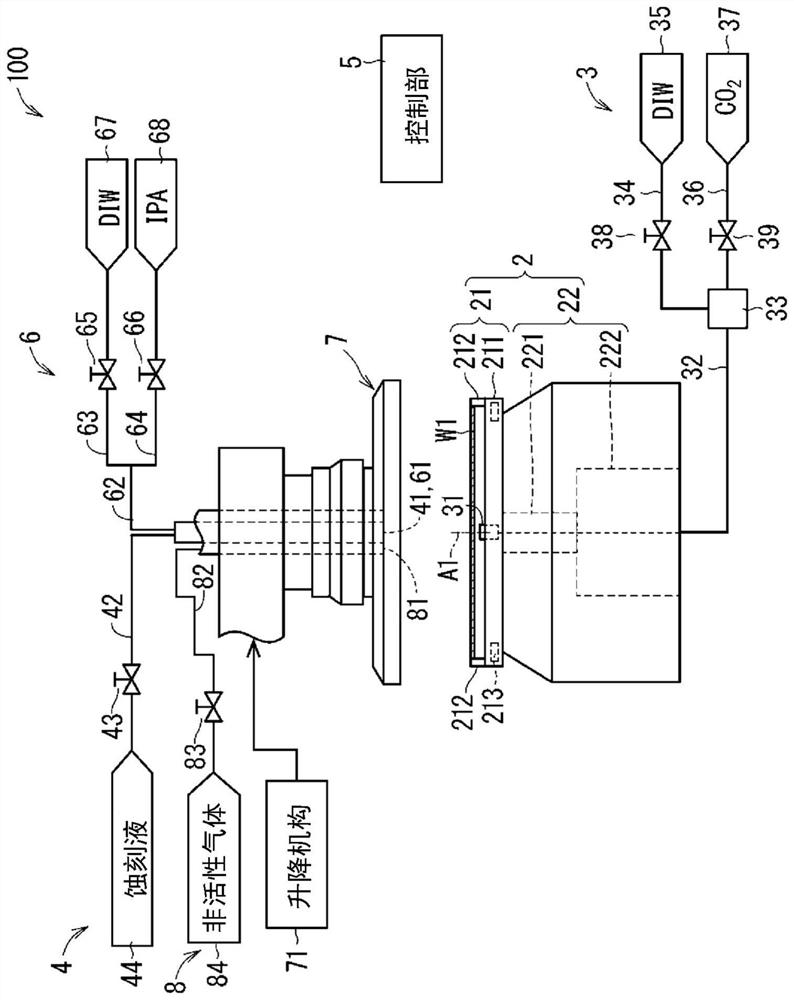

[0047] Below, refer to the attached Figure 1 Embodiments will be described. In addition, the drawings are diagrams schematically shown, and for convenience of description, the configuration is appropriately omitted or simplified. In addition, the relationship between the size and position of the configuration shown in the drawings is not necessarily described accurately, and can be appropriately changed.

[0048] In addition, in the description shown below, the same reference numerals are assigned to the same components and shown, and their names and functions are also set to be the same. Therefore, there are cases where detailed descriptions thereof are omitted to avoid repetition.

[0049]

[0050] figure 1 It is a diagram schematically showing an example of the configuration of the substrate processing apparatus 100 . The substrate processing apparatus 100 supplies an etchant to the surface of the substrate W1 to etch the surface of the substrate W1. The substrate W1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com