Real-time negative pressure dust removal system control equipment and method

A technology of dust removal system and control equipment, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as unstable performance and cumbersome control operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

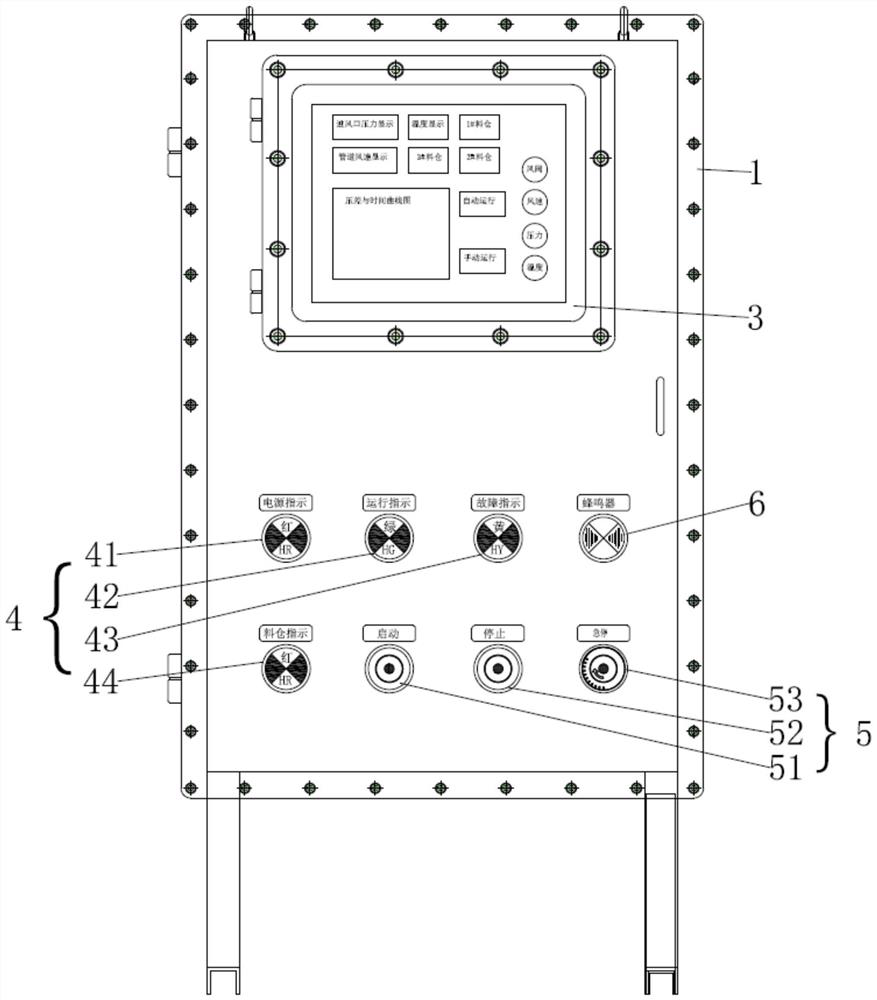

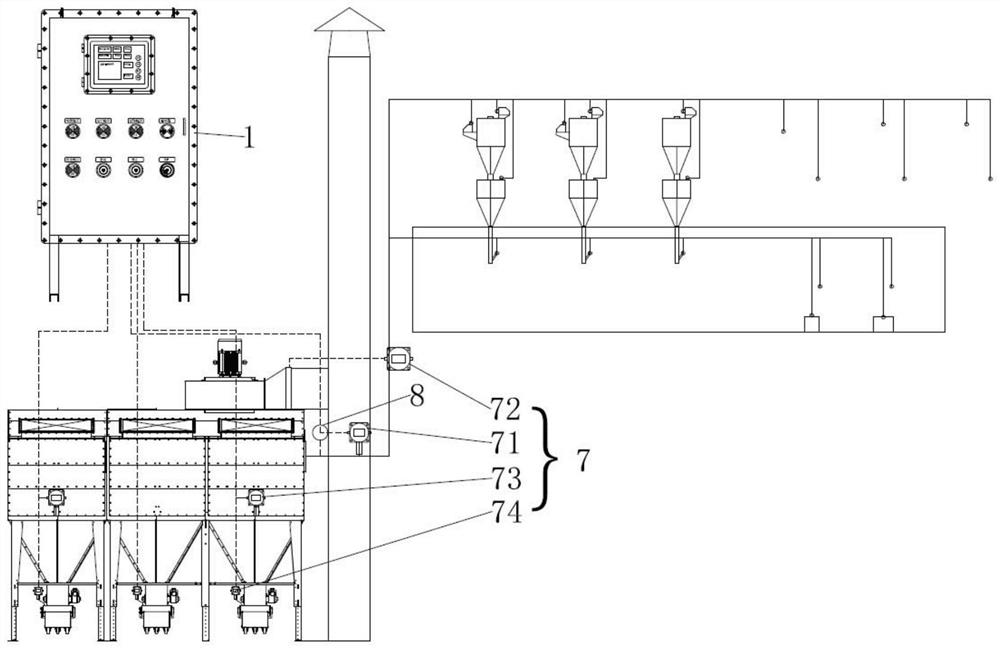

[0041] 1) Press the start button 51 to start the fan;

[0042] 2) The wind speed sensor 71 detects the wind speed in the main pipeline. When the wind speed of metal dust in the main pipeline is less than 23m / s, or when the wind speed of non-metallic dust is less than 18m / s, the control module 2 controls the fault indicator light 43 to light up and control the alarm The device 6 reports to the police, and the control state indicator light 4 displays the monitoring state correspondingly. At this time, the staff needs to check and confirm the wind speed monitoring value displayed on the man-machine interaction board 3;

[0043] 3) After confirming the abnormal situation, the staff operates the human-computer interaction board 3 to manual mode and eliminates the alarm, and adjusts the corresponding components in the negative pressure dust removal system. After the adjustment is completed, the staff confirms the human-computer interaction board 3 again After the wind speed is norma...

Embodiment 2

[0047] 1) Press the start button 51 to start the fan;

[0048] 2) The temperature sensor 73 detects the temperature in the pipeline. When the temperature in the pipeline is higher than the set value, the control module 2 controls the fault indicator light 43 to light up and controls the alarm 6 to alarm, and the control status indicator light 4 displays correspondingly Monitoring status, at this time, the staff needs to check the temperature monitoring value displayed on the human-computer interaction board 3 and confirm it;

[0049] 3) After confirming the abnormal situation, the staff operates the human-computer interaction board 3 to manual mode and eliminates the alarm, and adjusts the corresponding components in the negative pressure dust removal system. After the adjustment is completed, the staff confirms the human-computer interaction board 3 again After the temperature is normal, readjust the manual mode to automatic mode;

[0050] 4) Press the stop button 52, the fa...

Embodiment 3

[0053] 1) Press the start button 51 to start the fan;

[0054] 2) The differential pressure sensor 72 detects the differential pressure in the pipeline. When the differential pressure value is greater than the set reference value, the reference value is set as follows: when all branch valves are opened, the displayed differential pressure value rises by 15% as a reference value, the control module 2 controls the fault indicator light 43 to light up and controls the alarm 6 to alarm, and the control status indicator light 4 correspondingly displays the monitoring status. At this time, the staff needs to check the pressure difference monitoring value displayed on the man-machine interaction board 3 and To confirm, the control module 2 controls the opening of the air supply valve to compensate for the pressure difference. After the pressure difference returns to normal, the control module 2 controls the closing of the air supply valve;

[0055] 3) After confirming the abnormal si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com