Preparation method of sensor through electric field regulation and control

A technology of electric field regulation and sensor, which is applied in the direction of devices and coatings for coating liquid on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

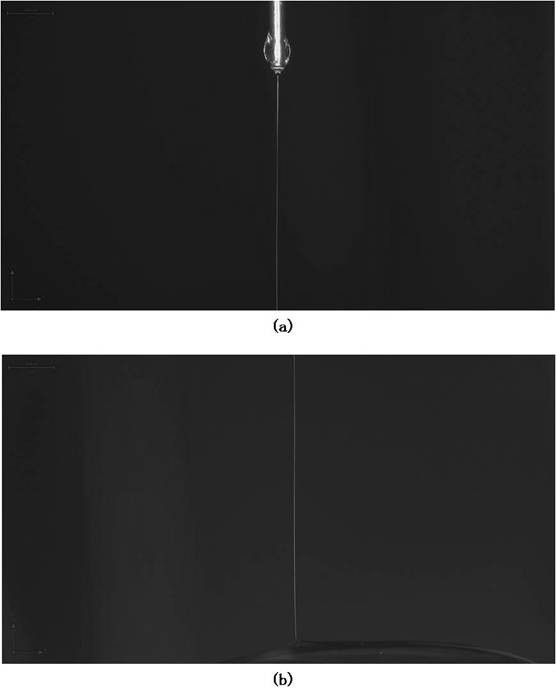

[0019] Such as figure 1 As shown, a sensor preparation method regulated by an electric field in the present invention uses a charged jet to move in an electric field under the action of an electric field force, and prepares a sensor sensitive structure by constructing an electric field to regulate the generation, focusing and motion deposition of the charged jet.

[0020] Build a first-level electric field to generate charged jets, including: material supply device 1, nozzle 2, positive high-voltage power supply 3, negative high-voltage power supply 8, and collection device 9. The material supply device 1 is connected with the spray head 2, and sends the fluid material into the spray head 2. The collecting device 9 is placed directly under the spray head 2, and the distance between the spray head 2 and the collecting device 9 is 1 mm to 100 mm. The positive high-voltage power supply 3 is connected to the nozzle 2, the negative high-voltage power supply 8 is connected to the c...

Embodiment 2

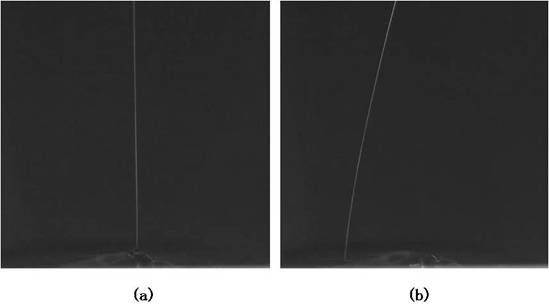

[0026] Such as figure 2 As shown, the difference from embodiment 1 is that the auxiliary electrode of embodiment 2 is a metal plate auxiliary electrode, and the metal plate auxiliary electrode 4 is in contact with the shower head 2 .

[0027] Build a first-level electric field to generate charged jets, including: material supply device 1, nozzle 2, positive high-voltage power supply 3, negative high-voltage power supply 7, and collection device 8. The material supply device 1 is connected with the spray head 2, and sends the fluid material into the spray head 2. The collecting device 8 is placed directly under the spray head 2, and the distance between the spray head 2 and the collecting device 8 is 1 mm to 100 mm. The positive high voltage power supply 3 is connected to the nozzle 2, the negative high voltage power supply 7 is connected to the collecting device 8, and the ground terminal of the high voltage power supply is grounded. A high-voltage electric field is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com