Building outer wall scaffold lifting safety driving equipment

A technology for safe driving and building exterior walls, which is applied to the accessories of scaffolding, scaffolding supported by building structures, and construction, etc., which can solve the problems of cumbersome operation of scaffolding, hidden dangers, and inability to descend.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

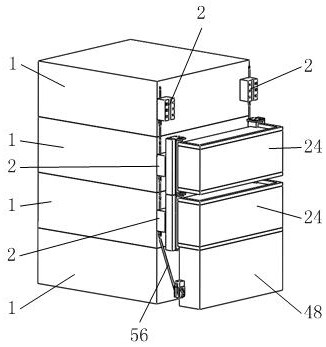

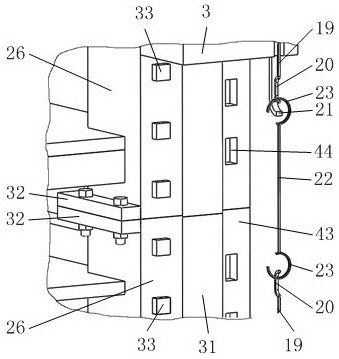

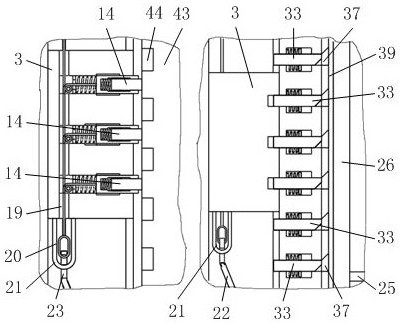

[0035] Such as figure 1 , 2 , 3, it includes guide seat mechanism 2, scaffolding mechanism 24, electric drive module B55, wherein as figure 1 , 2 As shown in , 3, several scaffolding mechanisms 24 are connected in sequence along the vertical direction and cooperate with two guide seat mechanisms 2 installed on the wall of each floor 1, and several scaffolding mechanisms 24 connected together are placed between two electric drive modules B55. Carry out vertical lifting under driving; The guide seat mechanism 2 and the scaffold mechanism 24 have the structure that prevents the scaffold mechanism 24 from falling due to the drive failure of the electric drive module B55 during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com