High rock burst roadway supporting system based on underground soft rock replacement technology

A roadway support, high impact technology, applied in tunnels, shaft linings, tunnel linings, etc., can solve problems such as damage, hidden dangers, and impact on the life, health and safety of construction workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

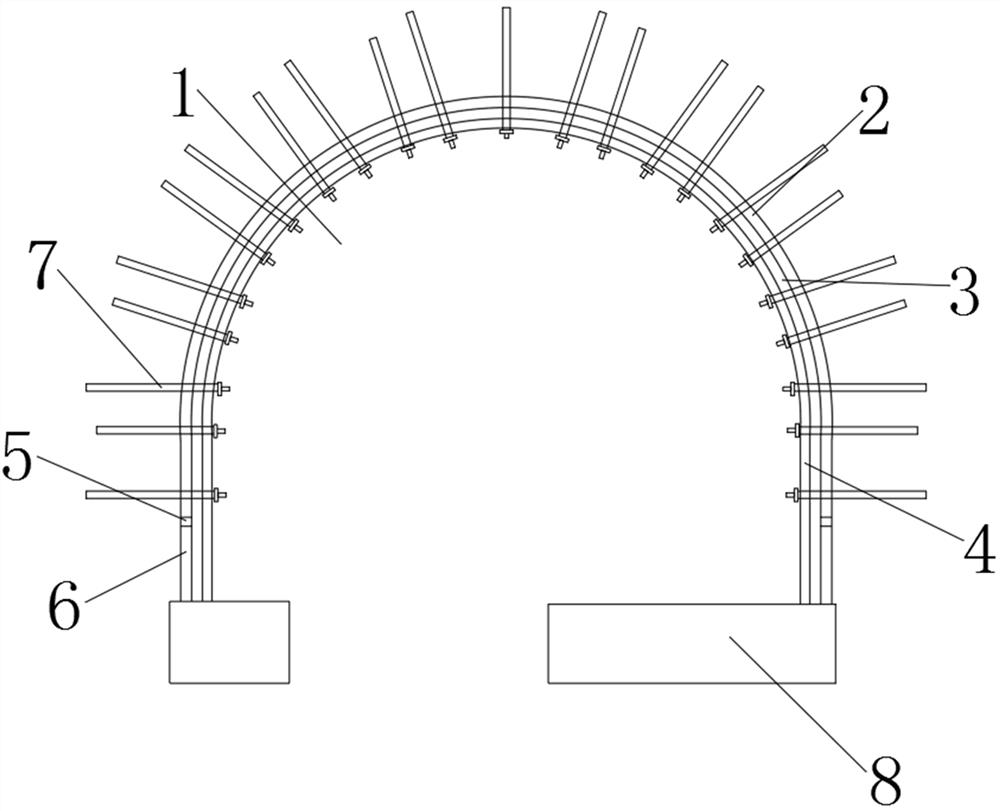

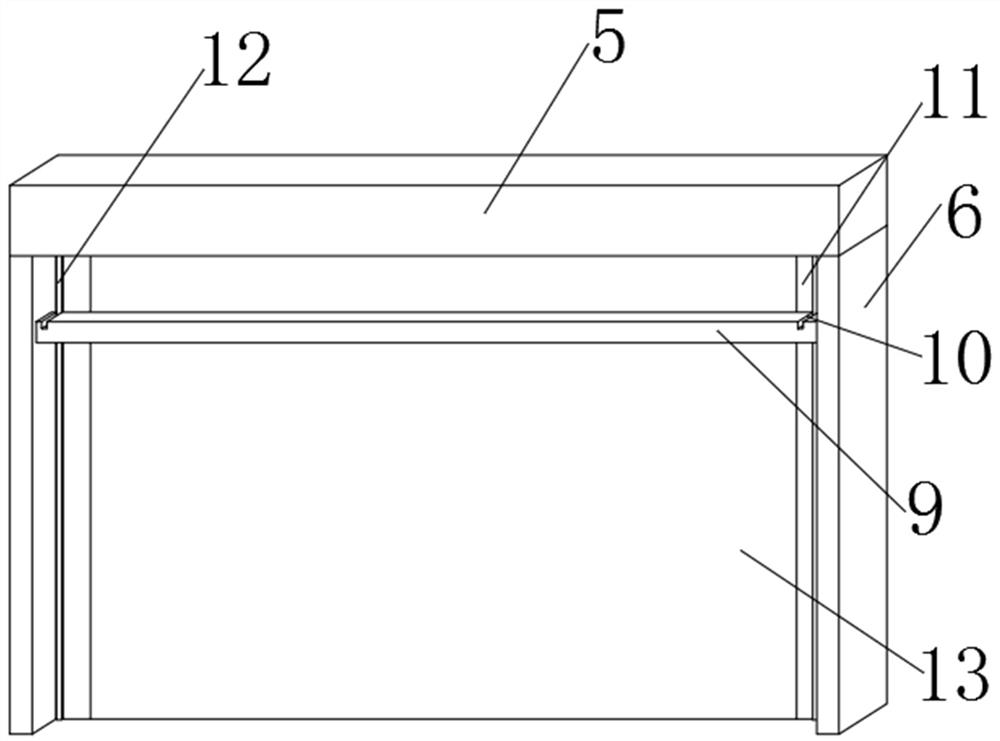

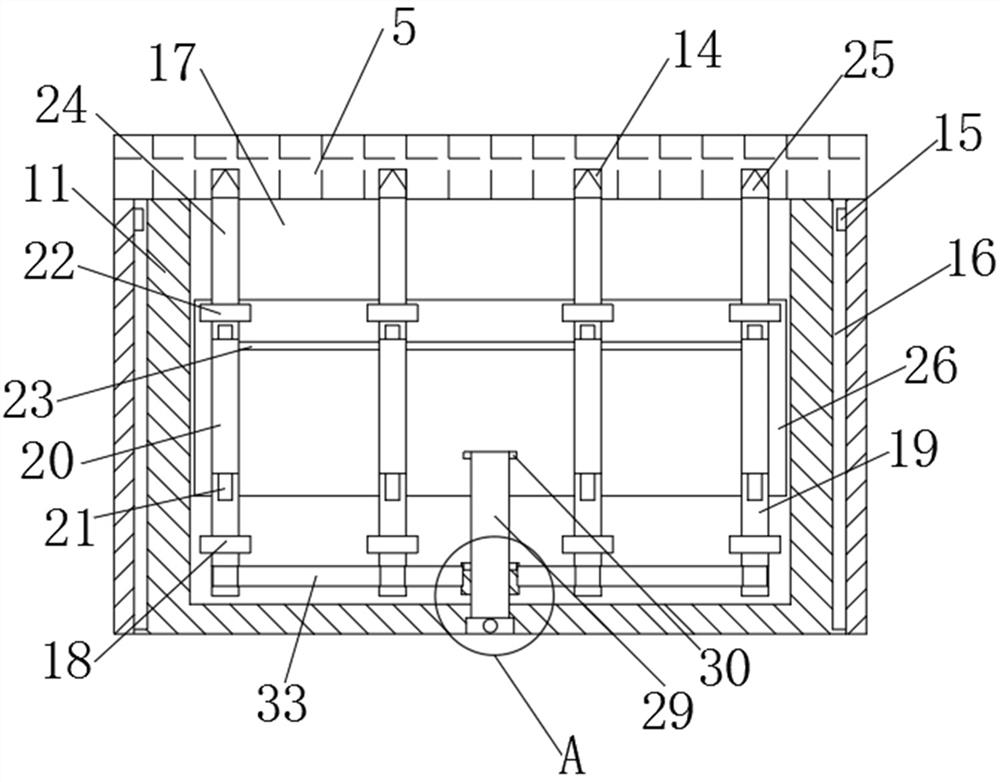

[0048] Such as Figure 1-6 As shown, a high impact rock pressure roadway support system based on underground soft rock replacement technology includes a roadway 1, a first support layer 2 is installed on the side of the roadway 1, and the side of the first support layer 2 The second support layer 3 is installed, the third support layer 4 is installed on the side of the second support layer 3, the ground support layer 8 is arranged on both sides of the lower end of the roadway 1, and the side of the roadway 1 A grouting anchor rod 7 is installed, and the grouting anchor rod 7 is fixed on the side of the third support layer 4, the lower end of the first support layer 2 is equipped with a base plate 5, and the lower surface of the base plate 5 is provided with Several groups of slots 14, several groups of risers 6 are fixed on the lower surface of the base plate 5, and limit rods 9 are fixed above the opposite faces of several groups of risers 6, and limit bars 9 are fixed on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com