Air pressure disc brake

A disc brake, air pressure technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of unequal height, complex mechanism, and inability to put friction plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

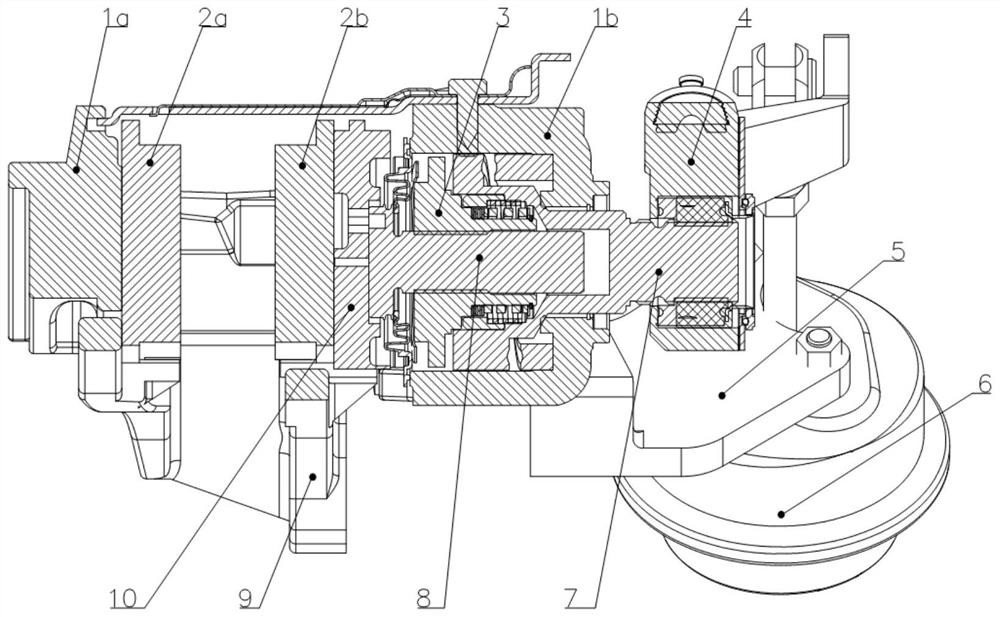

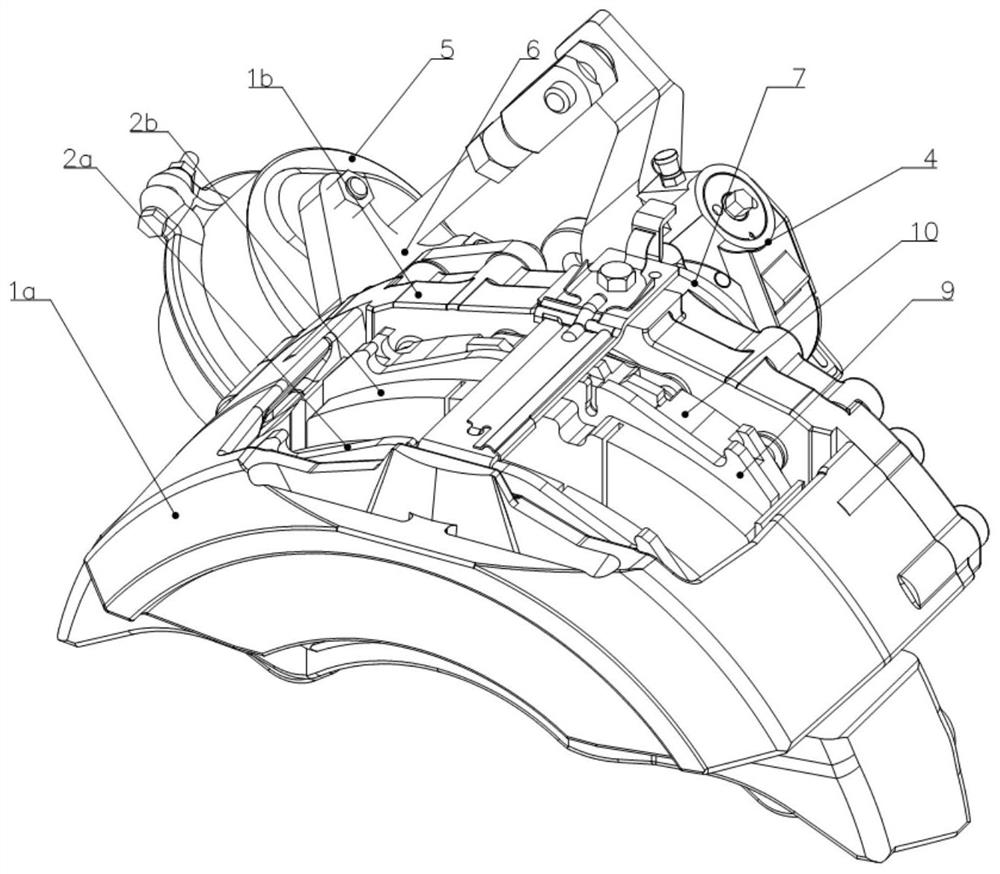

[0016] Embodiment: the invention provides a kind of technical scheme: as Figure 1-2 As shown, the disc brake includes a brake caliper body 1 composed of a housing and a bridge. The two are connected by four hexagon socket bolts, which reduces the difficulty of casting. There is an adjustment in the installation cavity of the housing. The mechanism is composed of a clutch assembly and a manual adjustment mechanism; the opening part of the caliper body has a pressure plate, a friction plate, and a brake disc; the outside of the caliper body is equipped with an adjustment arm, an air chamber bracket, and an air chamber.

[0017] When the air chamber on the air chamber bracket works, it will push the air chamber push rod and then push the adjustment arm to make it rotate; since the adjustment arm is connected with the adjustment shaft through the inner spline, the adjustment shaft will rotate with the rotation of the adjustment arm; the adjustment shaft When rotating, the clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com