Blade three-dimensional molded surface contour high-precision matching method based on self-reference surface

A datum surface and surface profile technology, which is applied in measuring devices, instruments, optical devices, etc., can solve problems such as splicing data errors, rotation axis and blade axis are not parallel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

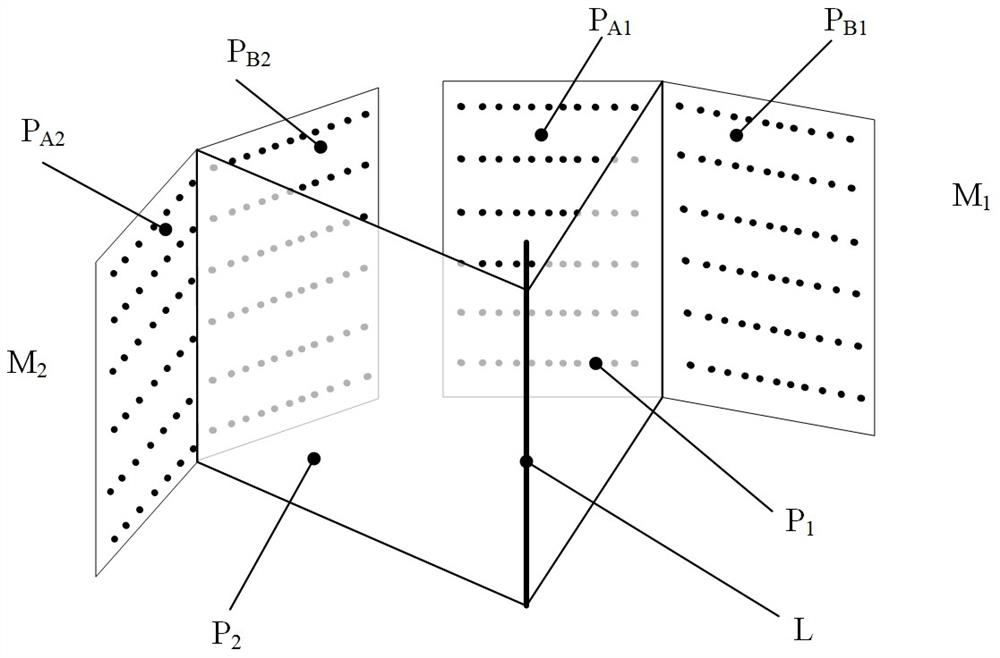

[0018] This embodiment provides a high-precision matching method for the three-dimensional profile of the blade based on the self-reference plane. The method discloses a calibration method for the axis of rotation. Data is more precise. The self-reference plane of the blade 200 refers to the two side reference planes A201, the reference plane B202 and the horizontal reference plane C203 processed during the processing of the blade 200. The reference plane A201 and the reference plane B202 intersect and are perpendicular to the reference plane C203. The surface is a common feature of all blades 200, and has a high flatness, which can be regarded as a high-precision plane feature. The method of this embodiment is to use the intersecting characteristics of two reference planes A201 and B202 to calibrate the axis of rotation .

[0019] A high-precision matching method for a three-dimensional profile of a blade based on a self-reference plane described in this implementation inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com