Punching die of die

A punching die and mold technology, applied in the direction of manufacturing tools, metal processing equipment, stripping devices, etc., can solve problems such as poor discharge of punching waste, difficulty in making dies, and concerns about the durability of dies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

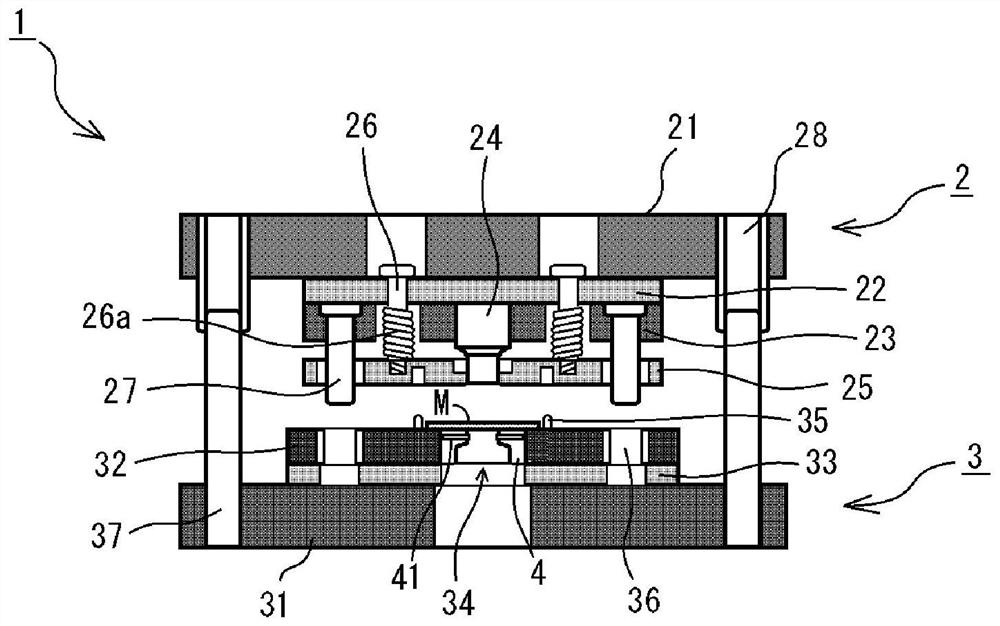

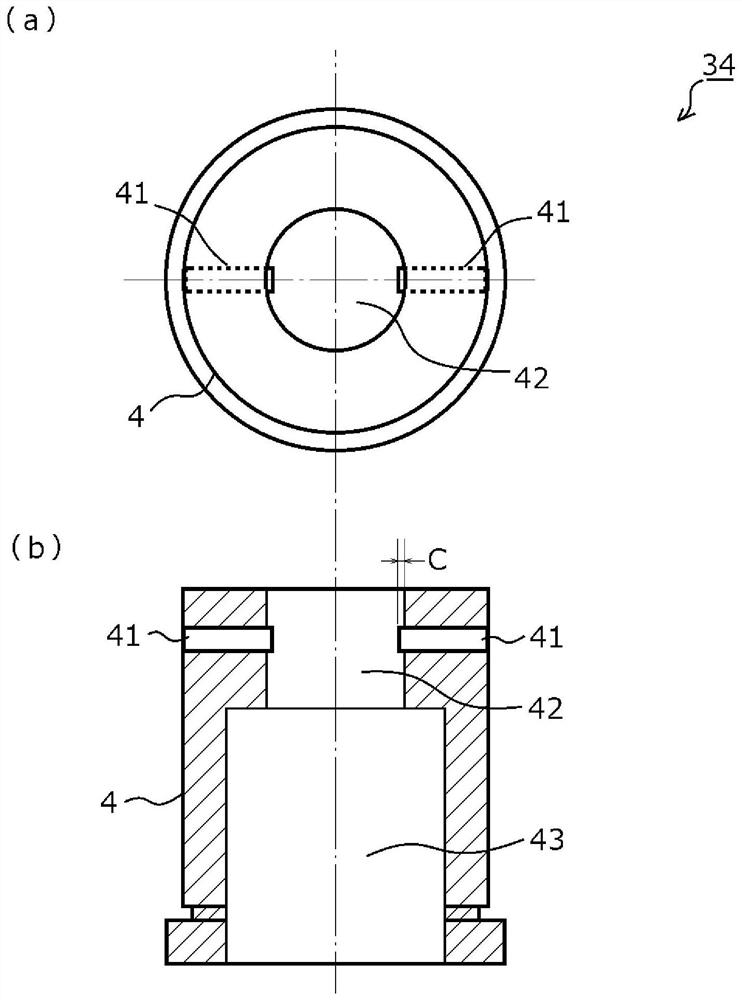

[0040] figure 1 The whole of the mold 1 according to this embodiment is shown. In actual product processing, there are cases where multiple sets of punches and dies are used, or other processing such as deep drawing is performed simultaneously with one die, but in order to facilitate understanding of the invention, in figure 1 exemplifies a typical die 1 for punching (piercing) with a set of punches and dies.

[0041] Such as figure 1 As shown, the mold 1 is composed of a set of upper mold 2 and lower mold 3 . The upper die 2 is attached to a slide of the press machine by, for example, a flange-type shank not shown. On the other hand, the lower die 3 is mounted on a backing plate of the press machine. In the upper die 2 , a punch holder 21 is arranged at the uppermost position, and a backing plate 22 and a punch plate 23 are arranged on the lower surface side thereof. At the center of the upper die 2 , a cylindrical punch 24 for circularly punching the material M to be pr...

no. 2 approach

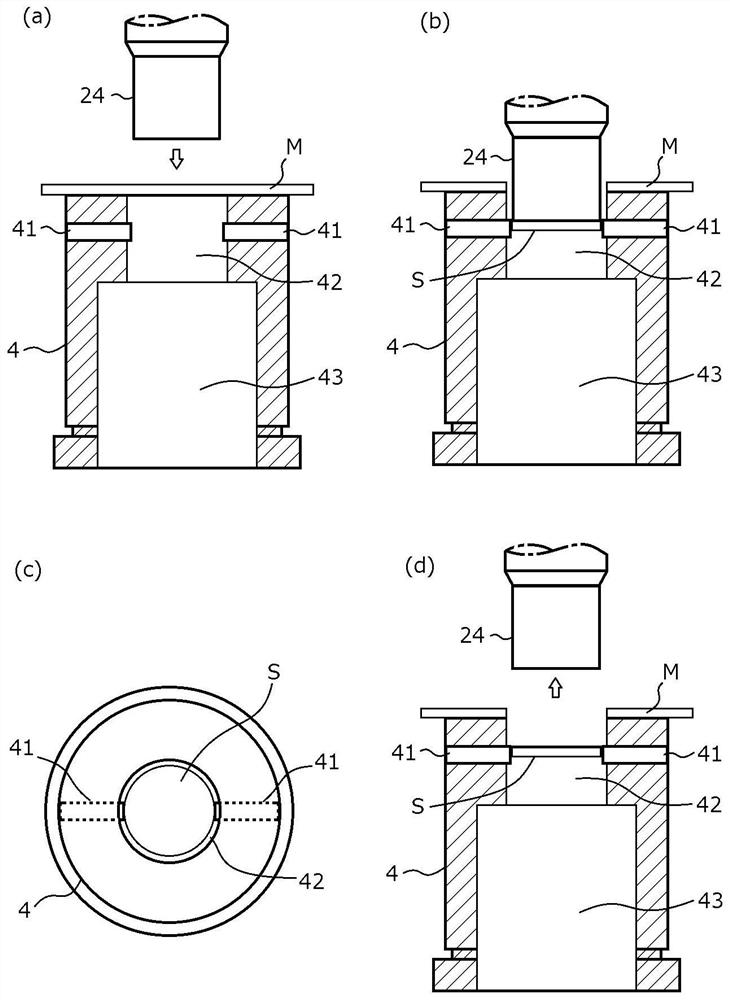

[0053] Next, while referring to Figure 4 The die 34 according to the second embodiment will be described. In addition, the die 34 according to the second embodiment is the same as that of the first embodiment except that the configuration of the resistance member 41 is different. Therefore, the same reference numerals are assigned to the same configurations as those of the first embodiment, and detailed description thereof will be omitted.

[0054] In the second embodiment, as Figure 4 As shown, instead of the rod-shaped member, the plunger 5 is used to constitute the elongated resistance member 41 . The plunger 5 includes a housing 51 as a main body, a front end portion 52 provided in an opening on one end side of the housing 51 to be able to move forward and backward, and an elastic member 53 biasing the front end portion 52 . The casing 51 is a substantially cylindrical member that is open at one end and has a bottom at the other end, and has a helical thread on its ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com