Crushing system of single-side driven grate cleaning crusher

A crushing system and crusher technology, applied in grain processing and other directions, can solve the problems of difficult processing and assembly, failure of the crushing transmission system, huge gear structure, etc., and achieve simple processing and assembly processes, low manufacturing difficulty, and compact layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of a crushing system of a unilaterally driven grate crusher will be described in detail below with reference to the accompanying drawings.

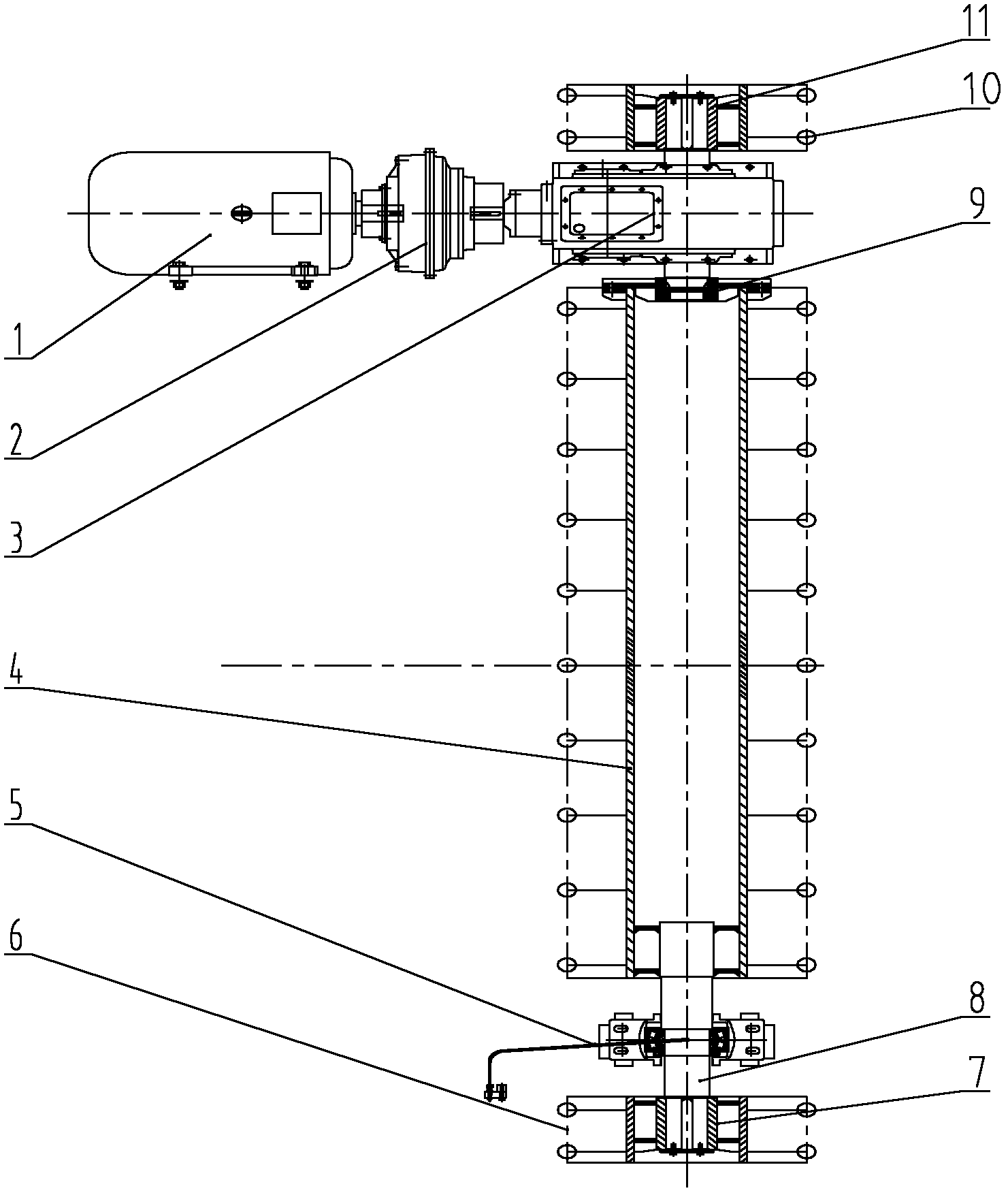

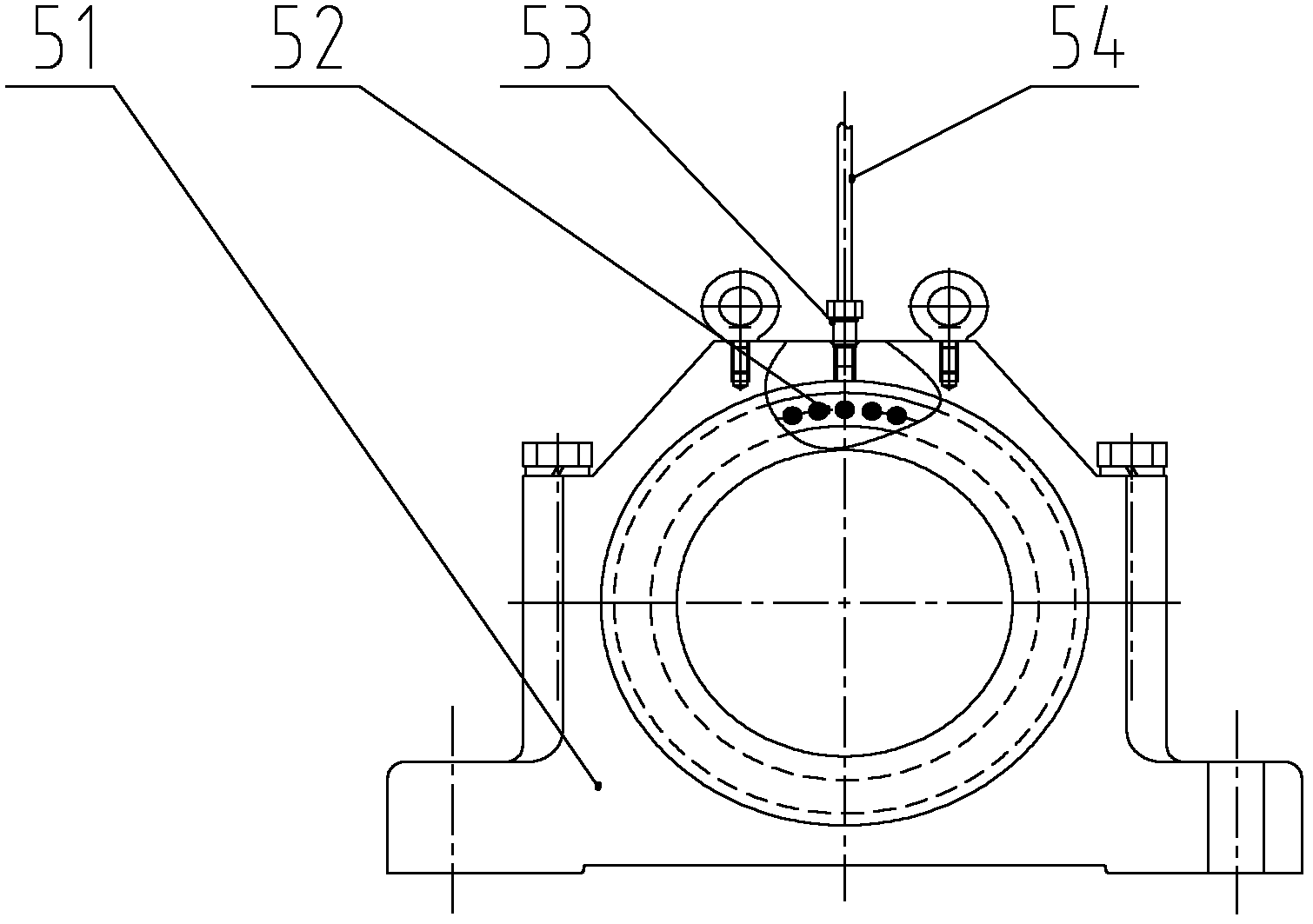

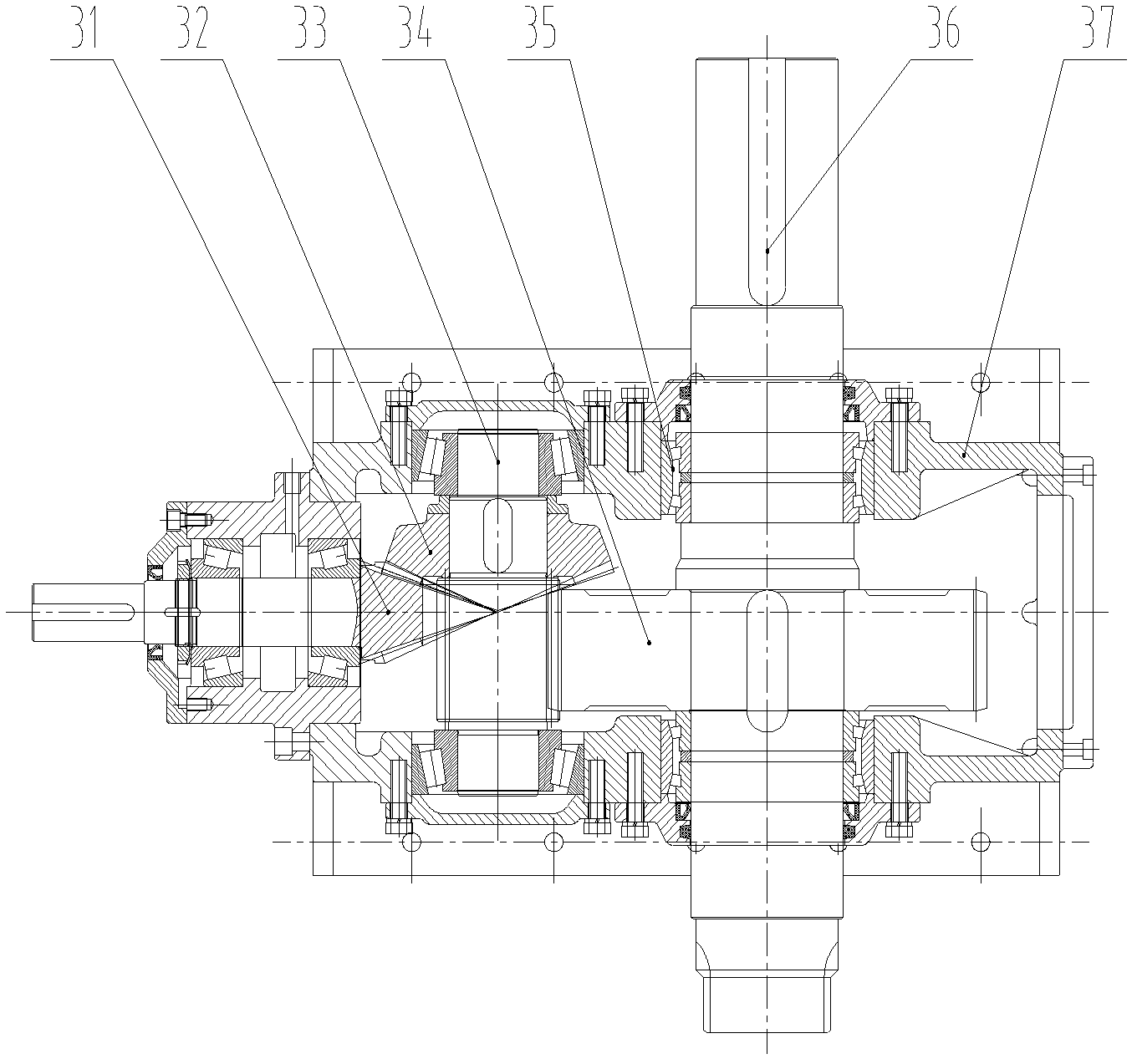

[0018] like figure 1 As shown, the crushing system of the unilaterally driven grate crusher includes a motor 1, a hydraulic coupling 2, a reducer 3, a main crushing roller 4, a crushing roller support assembly 5 and two secondary crushing rollers. The output shaft is connected with the input shaft of the reducer 3 through the hydraulic coupling 2, one end of the output shaft of the reducer 3 is connected with the first bushing 11 through a key, and the shaft end is fixed with the shaft end fixing plate and the bolt to fix the first bushing 11 , Weld the first crushing roller 10 on the first shaft sleeve 11, the first crushing roller 10 is cantilevered on the reducer 3, the other end of the output shaft of the reducer 3 and the connecting flange 9 are connected with the main One end of the crushing rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com