Anti-shielding, anti-interference and anti-shunting protection device and method for CMT electric arc additive material

A technology of anti-interference device and protective device, which is applied in the direction of electrode support device, device for providing/removing protective gas, additive processing, etc., and can solve problems such as metal oxidation, energy inconcentration, and arc instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments.

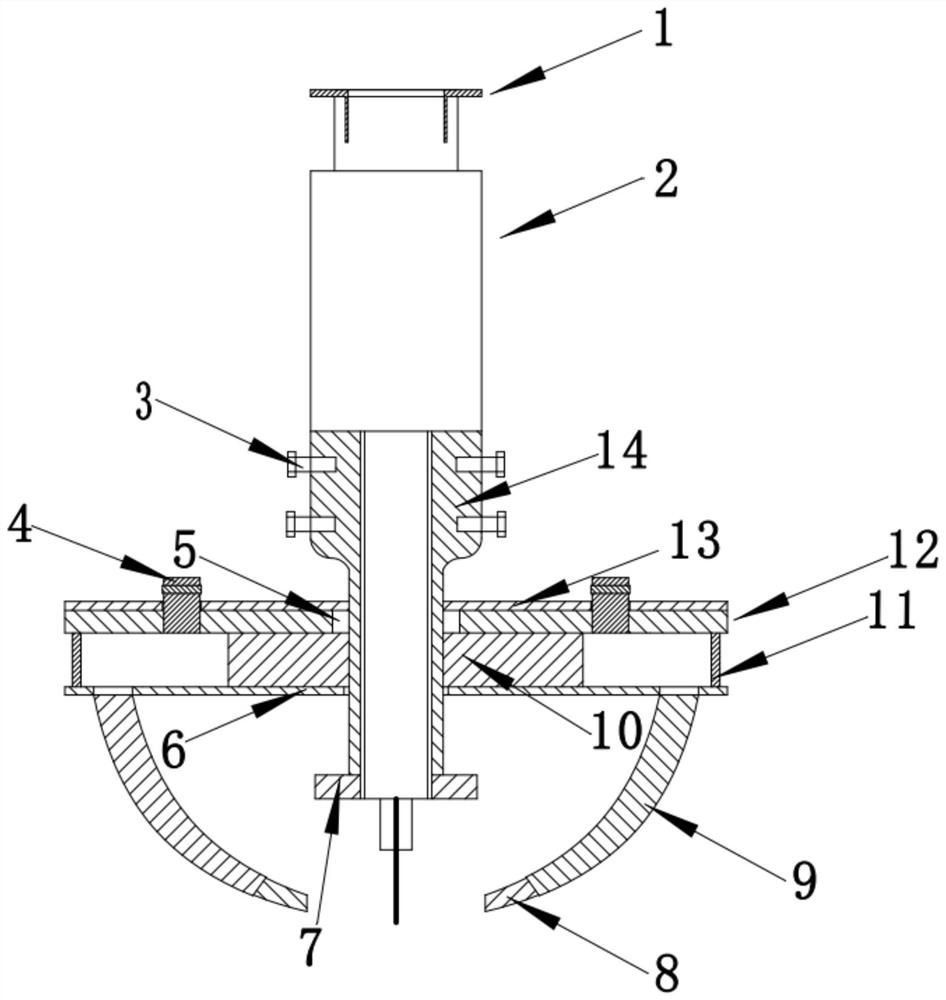

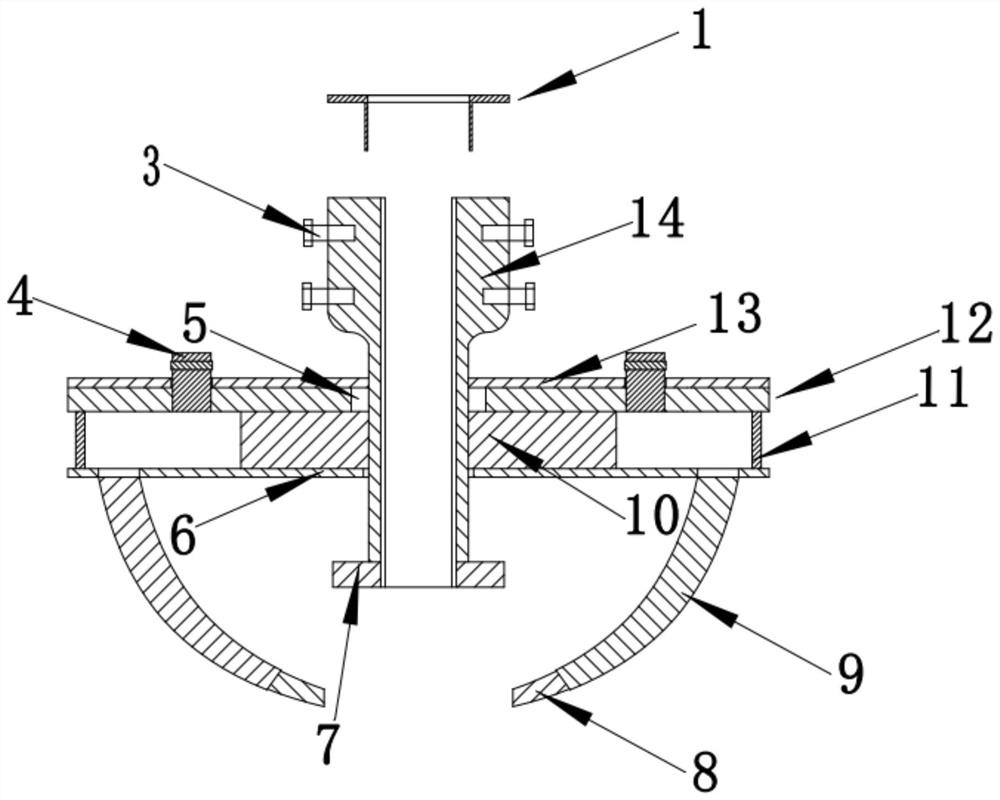

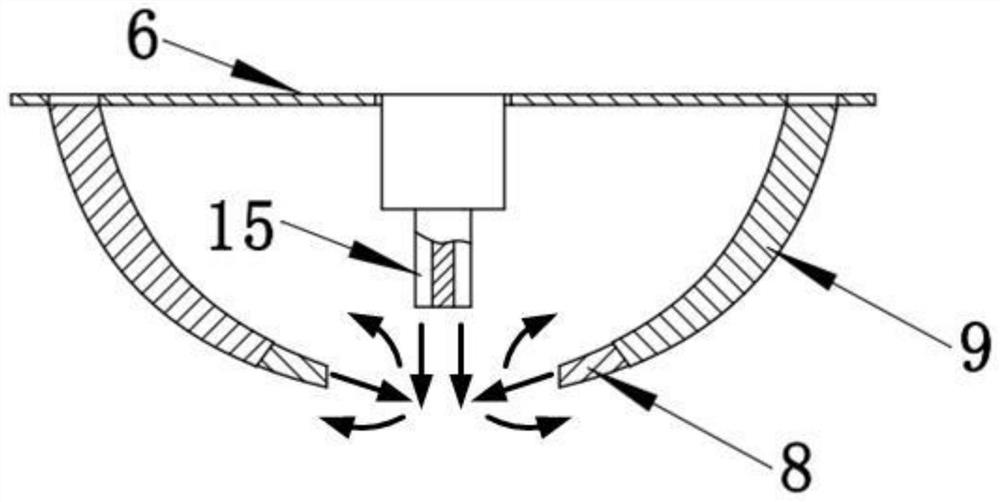

[0028] Such as Figure 1-6 As shown, the anti-shielding, anti-interference and anti-shunt protection device of the CMT arc additive includes a main body of the protection device, an anti-interference device, an anti-shield device and an anti-shunt device;

[0029] The main body of the protective device includes a fixed sleeve 14, which is fixed on the lower part of the welding torch body 2 through a hexagonal stud 3, and the upper part of the fixed sleeve 14 is thickened, and the hexagonal stud 3 fixes the fixed sleeve 14 through the thickened part On the welding torch body 2; the stainless steel support frame (7) is fixed on the end of the welding torch body 2, and its top surface is supported on the bottom surface of the fixing sleeve 14 for supporting the fixing sleeve, thereby improving the safety of the overall device.

[0030] The anti-jamming device includes two i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com