Ultrasonic driver and method

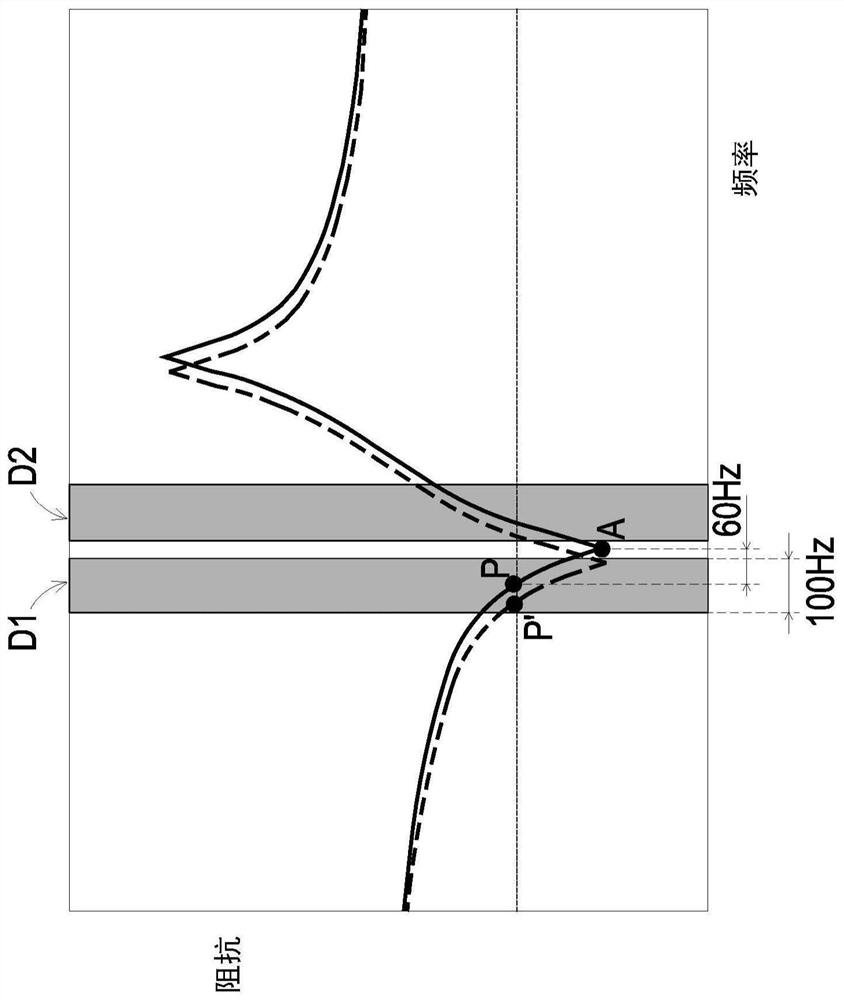

An ultrasonic and driver technology, applied in the field of ultrasonic drivers, can solve problems such as changes in the frequency domain impedance characteristics of ultrasonic tools, affecting the effect and quality of tool processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Some typical embodiments embodying the features and advantages of the present disclosure will be described in detail in the description in the following paragraphs. It should be understood that the present disclosure can have various changes in different embodiments without departing from the scope of the present disclosure, and that the descriptions and illustrations therein are illustrative in nature and not restrictive. This disclosure.

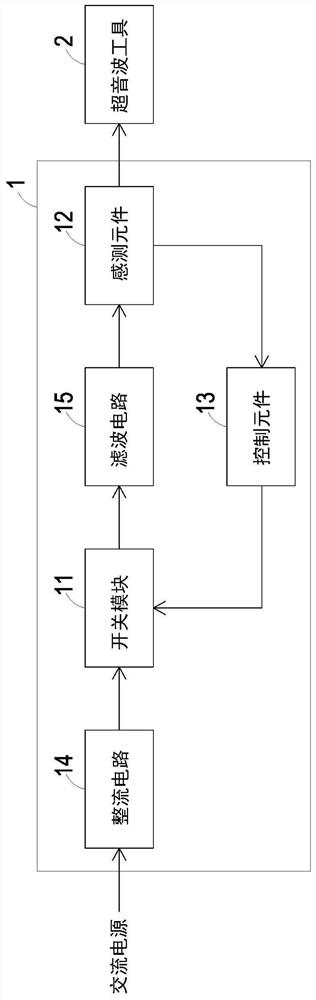

[0025] figure 1 It is a schematic diagram of the circuit structure of the ultrasonic driver and the ultrasonic tool in the preferred embodiment of the present disclosure. like figure 1 As shown, the ultrasonic driver 1 is used to drive the ultrasonic tool 2. The ultrasonic driver 1 includes a switch module 11, a sensing element 12, a control element 13, a rectifier circuit 14 and a filter circuit 15. The ultrasonic tool 2 can be any Tools that vibrate under the control of ultrasonic signals. The sensing element 12 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com