Intelligent cleaning line for locomotives

An intelligent cleaning and locomotive technology, applied in the field of robotics, can solve the problems of heavy weight, large stroke, short service life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

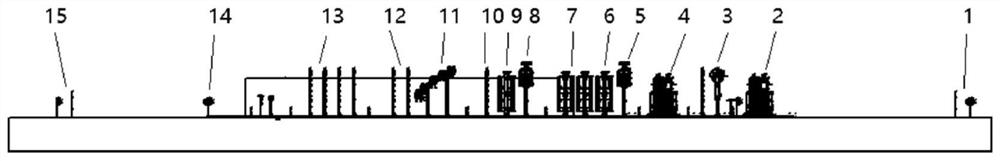

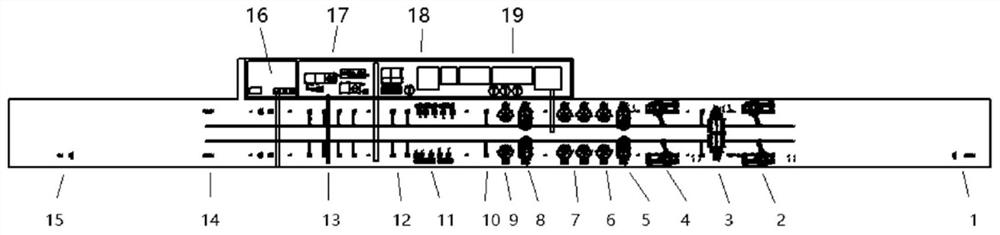

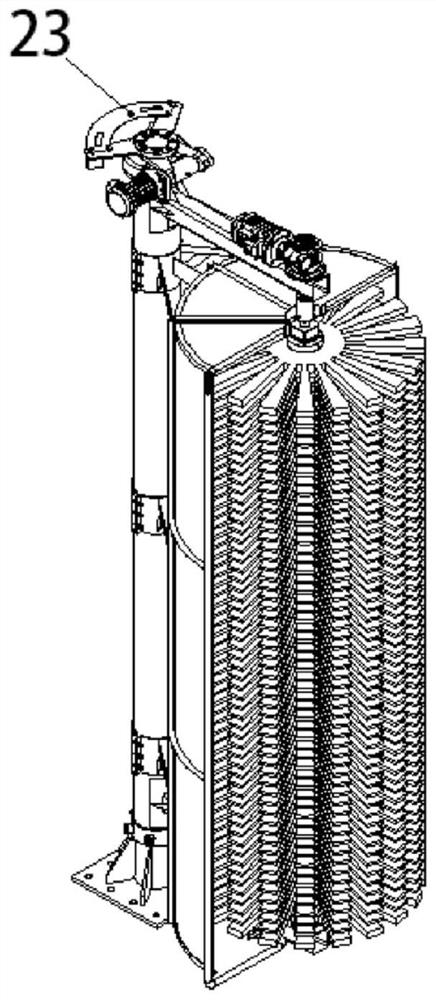

[0037] Such as Figure 1 to Figure 13 As shown, the intelligent cleaning line for locomotives includes the locomotive track, the car entrance arranged at the left end of the locomotive track, the left parking sign and light 15, the locomotive deceleration indicator light and the sign 14, which are arranged in turn from the car entrance to the right end of the locomotive track. Locomotive flushing and leak detection station 13, locomotive washing station 12, locomotive drying station 11, locomotive spraying station 10, locomotive side fine brushing station 9, locomotive side arc top fine brushing station 8, locomotive side washing worker Position 7, Locomotive side rough brushing position 6, Locomotive side arc top rough brushing position 5, Locomotive door and window scrubbing position 4, Locomoti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com