Split type steel billet guide roller

A guide roller, split-type technology, applied in the field of billet guide rollers, can solve the problems of poor cooling effect, easy deformation, difficult repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention will be described in detail below with reference to the accompanying drawings and examples.

[0051] It is worth noting that the "upper" "lower" orientation described herein is determined relative to the viewing angle of the accompanying drawings, it is only for convenience of description, it is not possible to understand the limitations of the technical solution.

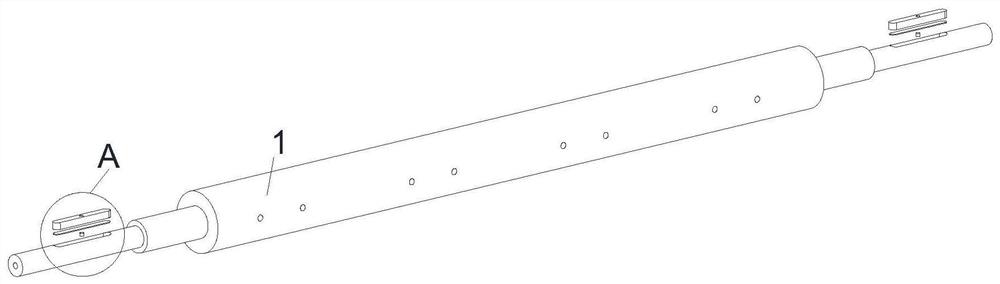

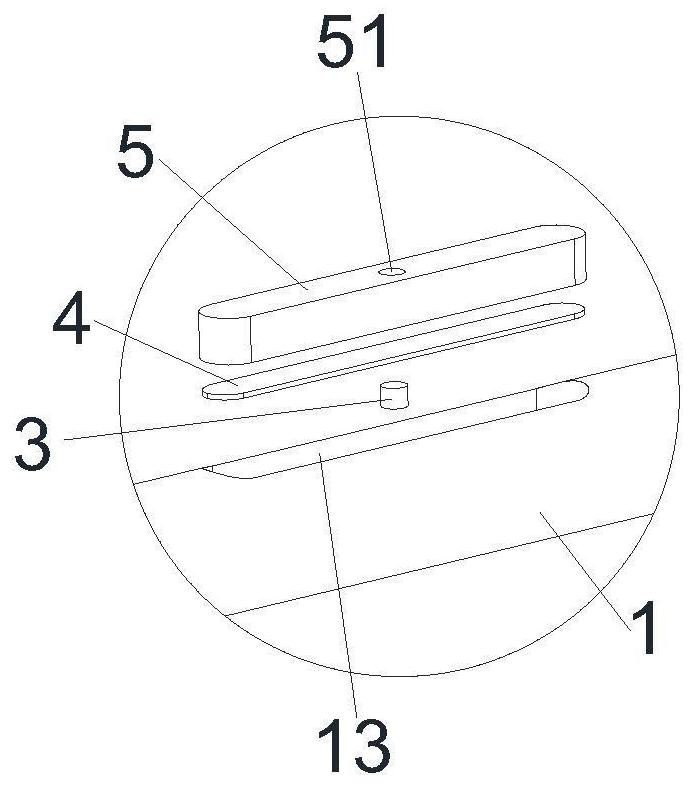

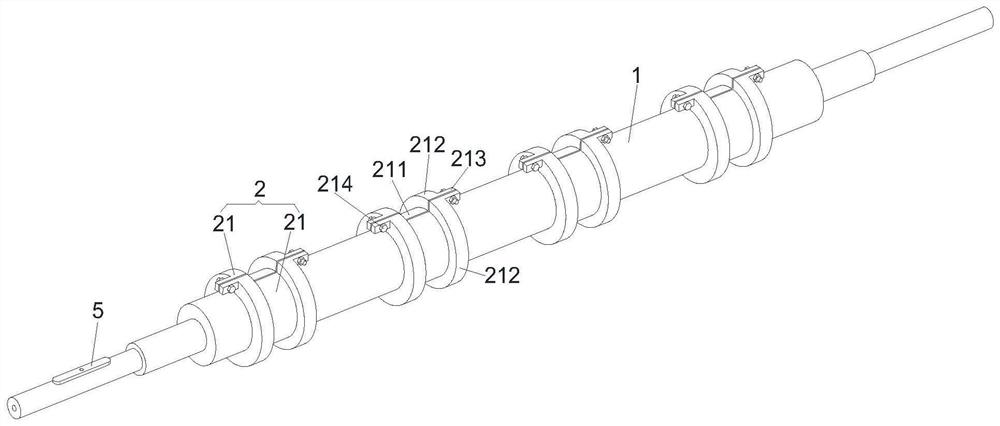

[0052] See Figure 1 - Figure 5

[0053] A split steel blank guide roller, including the shaft body 1, a clamp group 2 fixed to the shaft body 1, a plug 3; the clamp group 2 includes two clamps 21, the clamp 21, includes a clamp sleeve 211, and a stop ring 212 fixed to both ends of the clamp sleeve 211; the length direction of the shaft body 1 is opened in the shaft body 1; the position of the shaft body 1 corresponds to the position of the ring 212 in the circumferential direction. There is a cooling side hole 12 communicating with the cooling long hole 11; there is a cooling ring 2121 inside the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com