Diatom mud material processing method

A material processing and diatom mud technology, which is applied in clay processing equipment, chemical instruments and methods, grain processing, etc., can solve the problems of long processing cycle of diatom mud materials and inability to process diatom mud materials quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0063] Attached below Figure 1-10 In detail, a diatom mud material processing method includes the following steps:

[0064] S1. Decomposing the crushed diatoms under high temperature and high pressure;

[0065] S2, mixing the decomposed diatoms with clay;

[0066] S3, mixing and stirring diatoms and bonding;

[0067] S4. Complete the preparation of the diatom mud material.

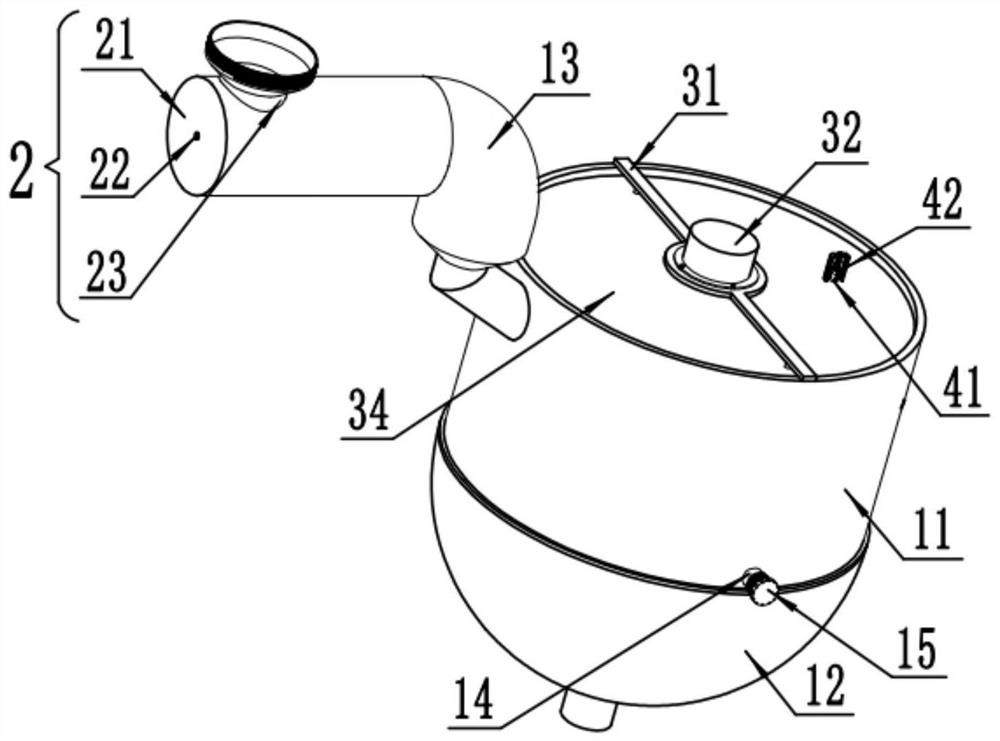

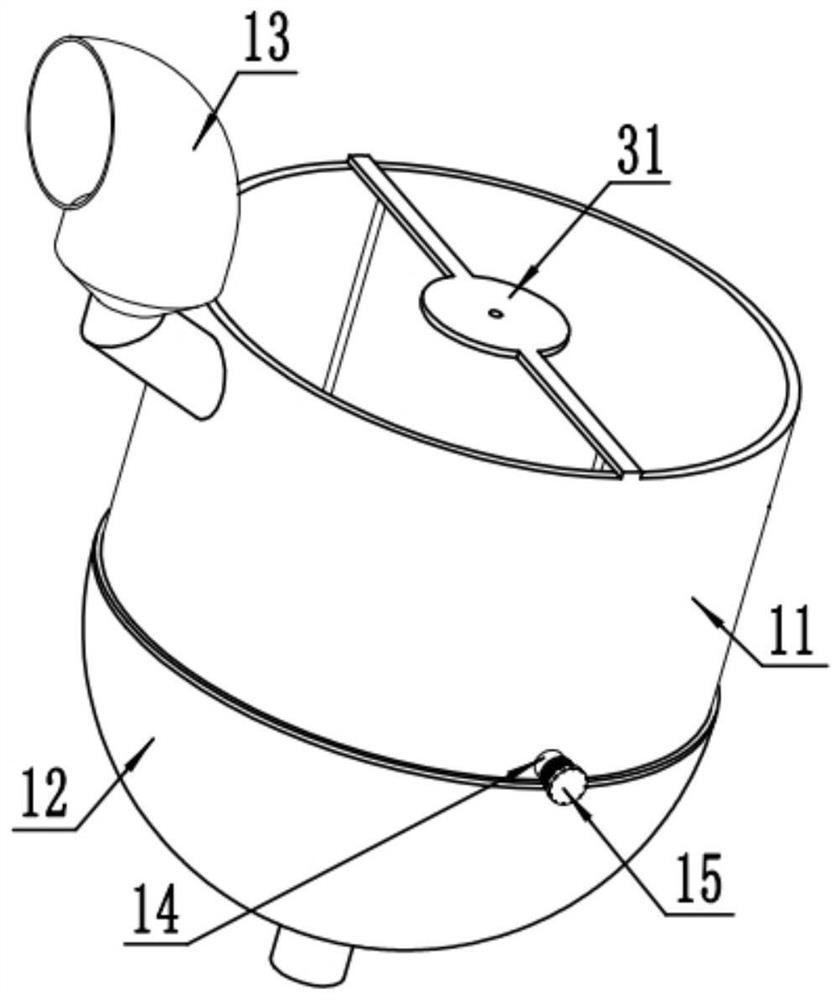

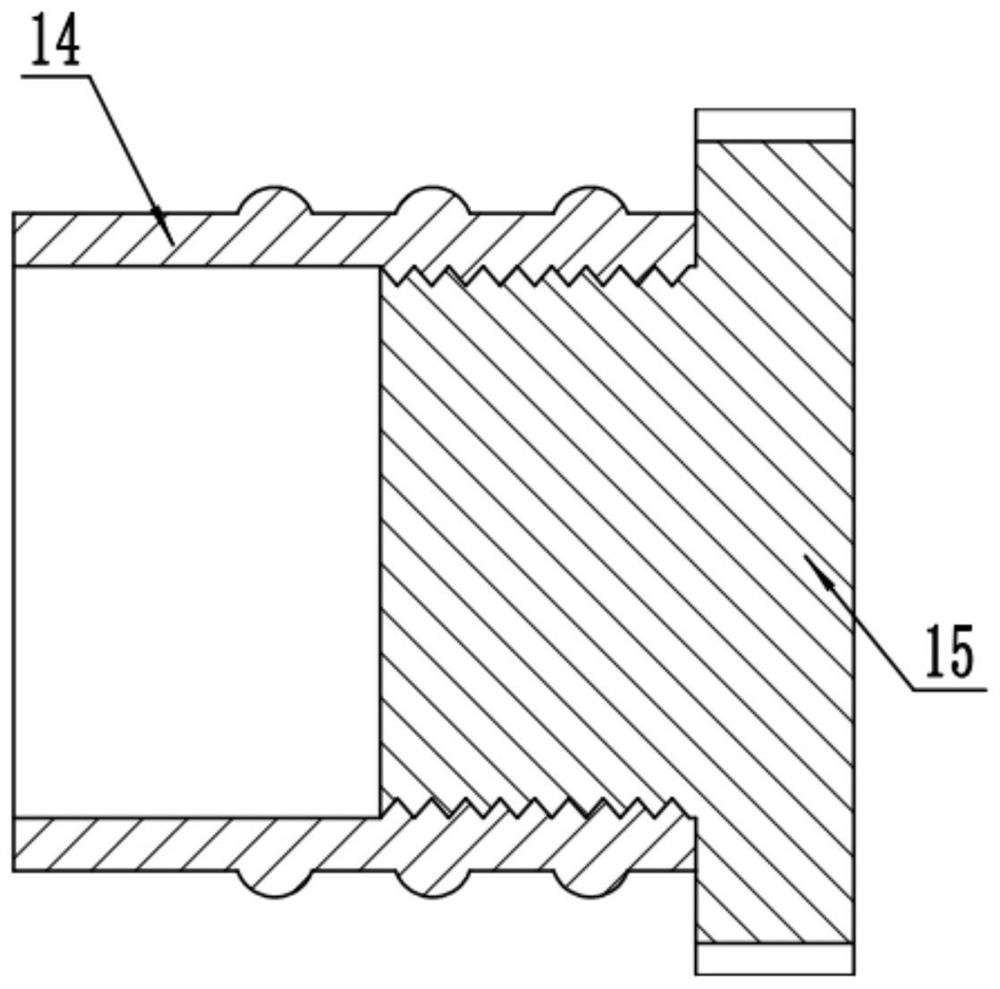

[0068] Attached below figure 1 , 2 , 5, 6 and 7 describe in detail that the diatom ooze material processing method also uses a diatom ooze material processing device, which includes a treatment chamber 11, a heating base plate 12, a pressurizing member and a protection Components, the bottom of the processing chamber 11 is fixedly connected with a heating base plate 12 by welding, the processing chamber 11 is connected with a pressurizing member capable of pressurizing the processing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com