Composite plastic microbubble plate building outer wall fireproof heat preservation system

A technology for building exterior walls, fire prevention and heat preservation, applied in building heat preservation materials, heat preservation, fire prevention and other directions, can solve problems such as failure to report fire in time, insufficient wall stability, and poor wall fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

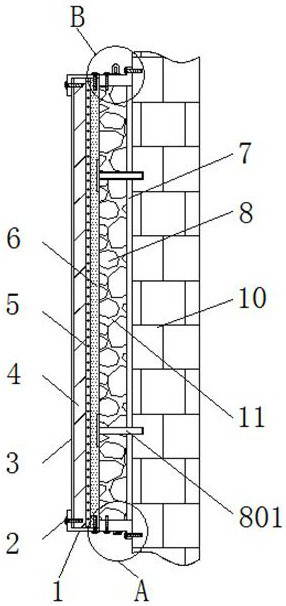

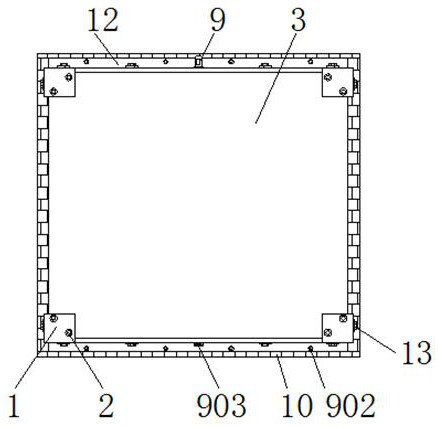

[0034] Example 1: See Figure 1-8 , a composite plastic micro-foam board building exterior wall fire protection and heat preservation system, including a wall 10, also includes a support structure 8 to prevent fire collapse, an alarm structure 9 to prevent fire spread, and a fixed structure to increase the stability of the wall;

[0035] One side of the wall body 10 is provided with a bonding layer 7, and one side of the bonding layer 7 is connected with a fireproof heat preservation board 11, and the support structure 8 is arranged inside the fireproof heat preservation board 11;

[0036] The top and bottom ends of the fireproof insulation board 11 on one side of the wall 10 are equipped with right-angle irons 12, and the alarm structure 9 is arranged on the outer surface of the right-angle irons 12;

[0037] One side of the fireproof insulation board 11 is provided with a mortar leveling layer 6, and one side of the mortar leveling layer 6 is connected with a mesh cloth 5, a...

Embodiment 2

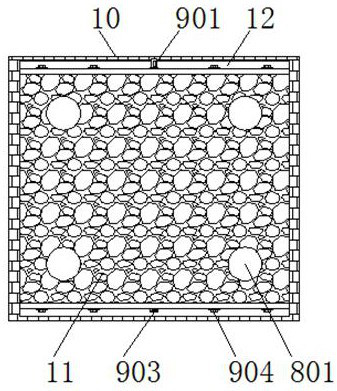

[0043]Embodiment 2: The support structure 8 includes fixing bolts 801, fireproof skeleton 802, heat preservation particles 803 and cavity 804, the fixing bolts 801 are evenly arranged on one side of the fireproof heat preservation board 11, and the fireproof skeleton 802 is arranged outside the fireproof heat preservation board 11 , the cavity 804 is set inside the fireproof insulation board 11, and the inside of the cavity 804 is filled with insulation particles 803;

[0044] The number of fixing bolts 801 is four, and one end of the fixing bolts 801 extends to the inside of the fireproof insulation board 11;

[0045] The material of the fireproof frame 802 is thermosetting resin, and the material of the heat preservation particles 803 is ultrafine hollow ceramics;

[0046] Specifically, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, when this mechanism is used, when a fire occurs, the internal fireproof insulation board 11 is heated, and the thermosettin...

Embodiment 3

[0047] Embodiment 3: The alarm structure 9 includes a buzzer 901, a first expansion bolt 902, a smoke sensor 903 and a second expansion bolt 904, the buzzer 901 is arranged at the top center of the wall 10 above the fireproof insulation board 11, and The smoke sensor 903 is arranged at the center of the bottom of the right-angle iron 12 under the fireproof insulation board 11, the second expansion bolt 904 is evenly arranged at the end of the right-angle iron 12 away from each other, and the first expansion bolt 902 is evenly arranged on one side of the right-angle iron 12. side;

[0048] One end of the second expansion bolt 904 extends to the interior of the fireproof insulation board 11, and one end of the first expansion bolt 902 extends to the interior of the wall 10;

[0049] Specifically, such as figure 1 , figure 2 , image 3 , Figure 7 and Figure 8 As shown, when using this mechanism, the right-angle iron 12 can play a good role in supporting and stabilizing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com