A kind of anti-loosening bolt

A technology of anti-loosening bolts and bolt caps, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of reduced installation efficiency, wear, and reduced fastening effect of glue, and achieves improved fastening effect, simple glue application, and uniform glue application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail.

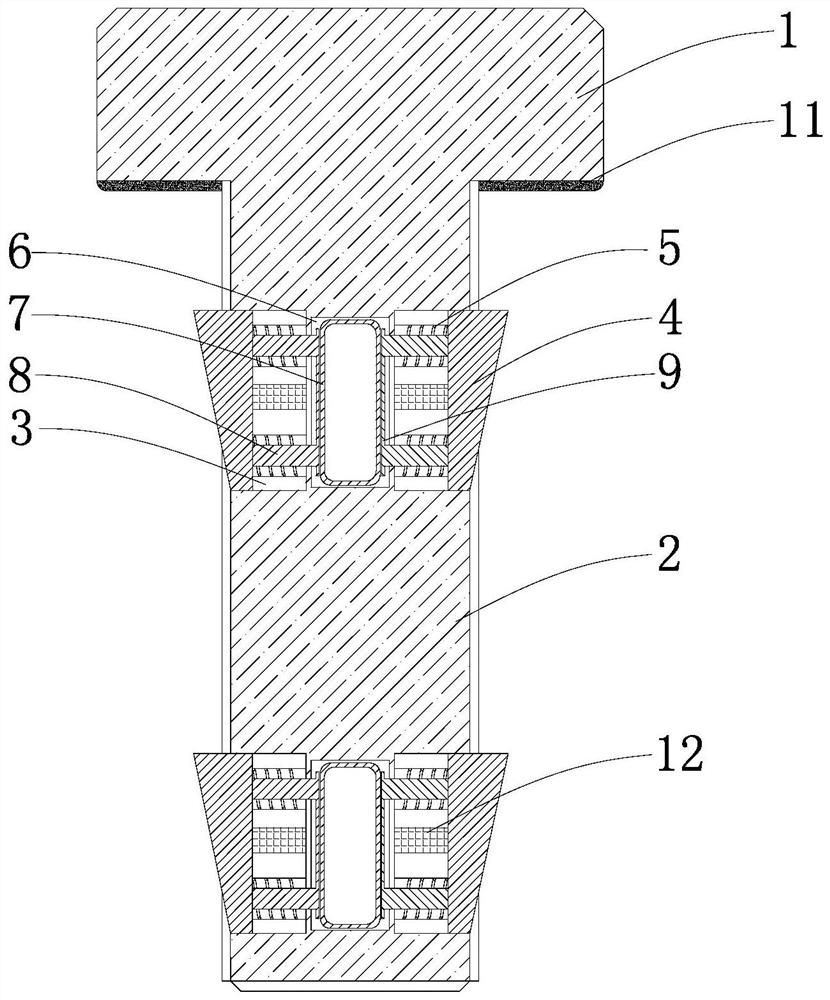

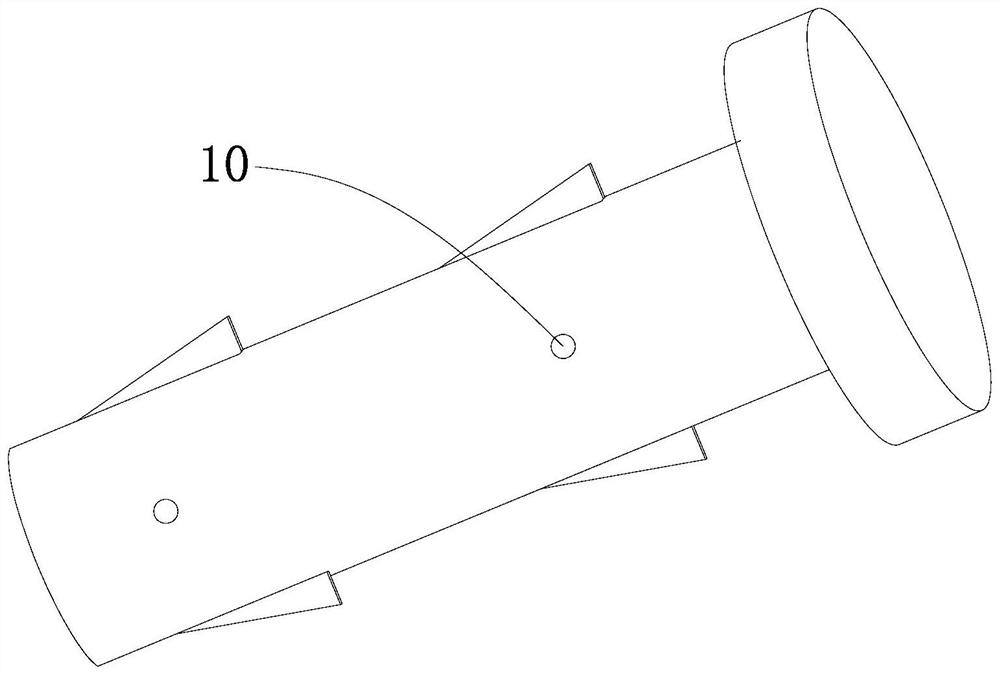

[0024] This embodiment proposes a kind of anti-loosening bolt, such as figure 1 with 2 As shown, it includes a bolt cap 1 and a threaded bolt post 2. Two pairs of symmetrical grooves 3 are provided on the side wall of the bolt post 2, and the two pairs of grooves 3 are respectively arranged on the upper and lower parts of the bolt post 2. . The groove 3 is provided with a right-angled triangle limiting plate 4, the right-angled end of the right-angled triangle limiting plate 4 faces the bolt cap 1, and the smallest acute-angled end faces the end of the bolt column 2 away from the bolt cap 1; the right-angled triangle limiting plate 4 A return spring 5 is provided between the bottom surface of the groove 3. When the return spring 5 is not compressed, the right-angled triangle limiting plate 4 protrudes from the side wall of the bolt post 2. When the returning spring 5 is compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com