Steel rail detection method for railway construction

A detection method and rail technology, applied in the direction of railway vehicle shape measuring device, railway car body parts, railway auxiliary equipment, etc., can solve the problems of cumbersome operation, affecting the official traffic speed, slow rail detection speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

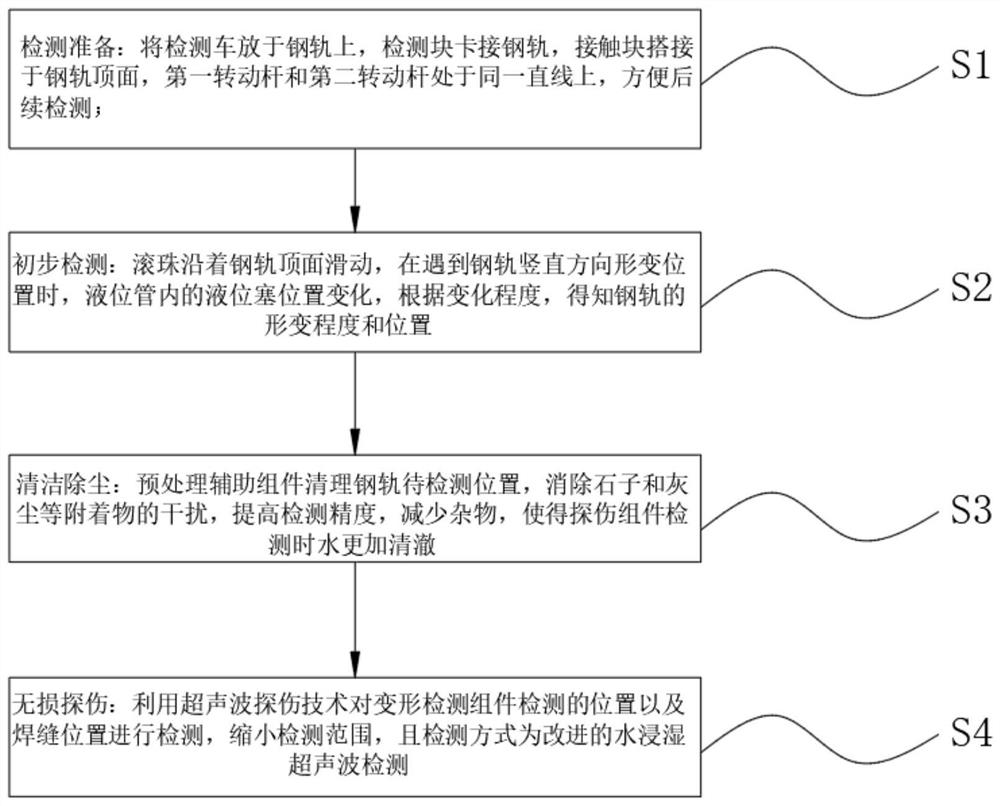

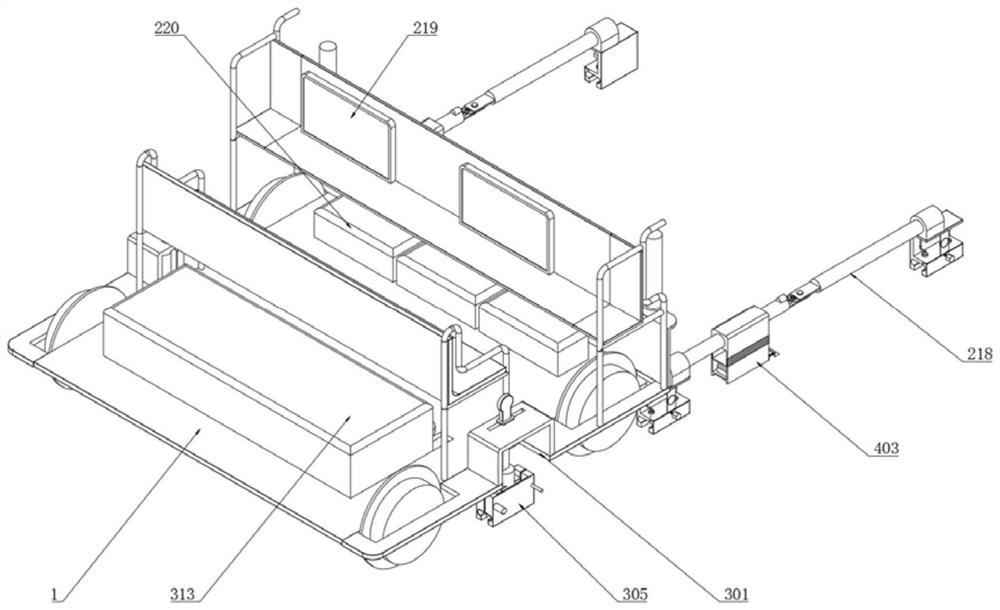

[0047] Example: such as Figure 1-10 As shown, the present invention provides the technical scheme of rail detection method for railway construction, comprising the following steps:

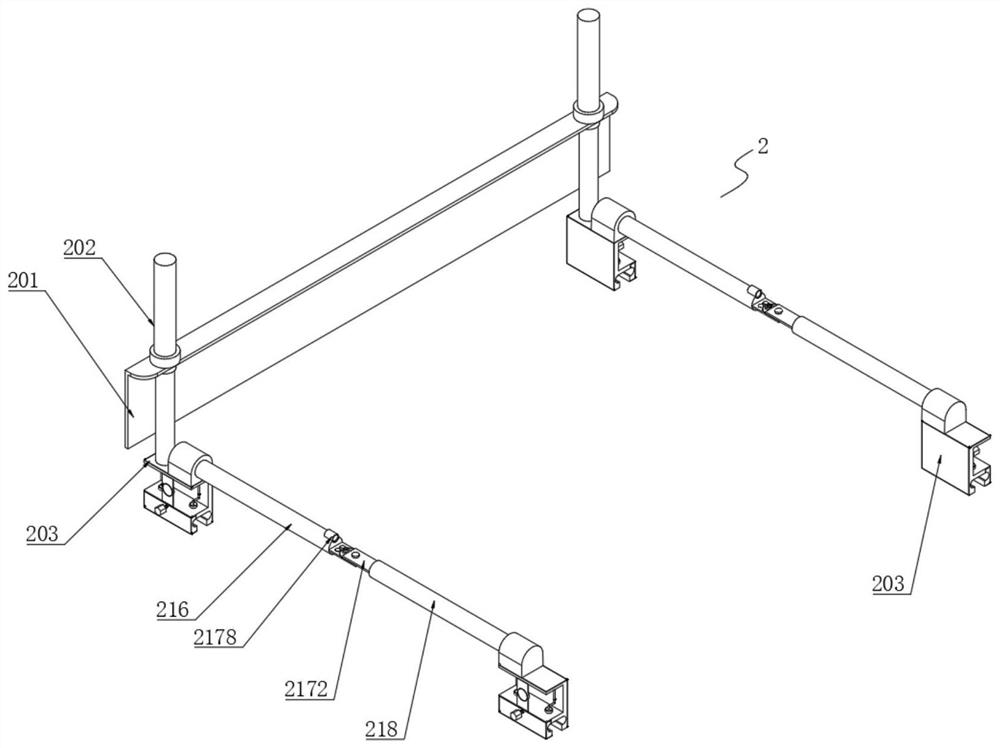

[0048] S1: Inspection preparation: put the inspection vehicle 1 on the rail, the inspection block 203 is clamped to the rail, the contact block 403 is lapped on the top surface of the rail, and the first rotating rod 216 and the second rotating rod 218 are on the same straight line to facilitate subsequent inspection ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com