A Strength Prediction Method for High-Entropy Alloys with Dual-Phase Structure

A high-entropy alloy, high-strength technology, applied in the field of high-entropy alloy phase change strengthening calculation, can solve the problems that the theoretical model of dual-phase high-entropy alloy phase change strengthening has not been established, and there is no phase interface strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

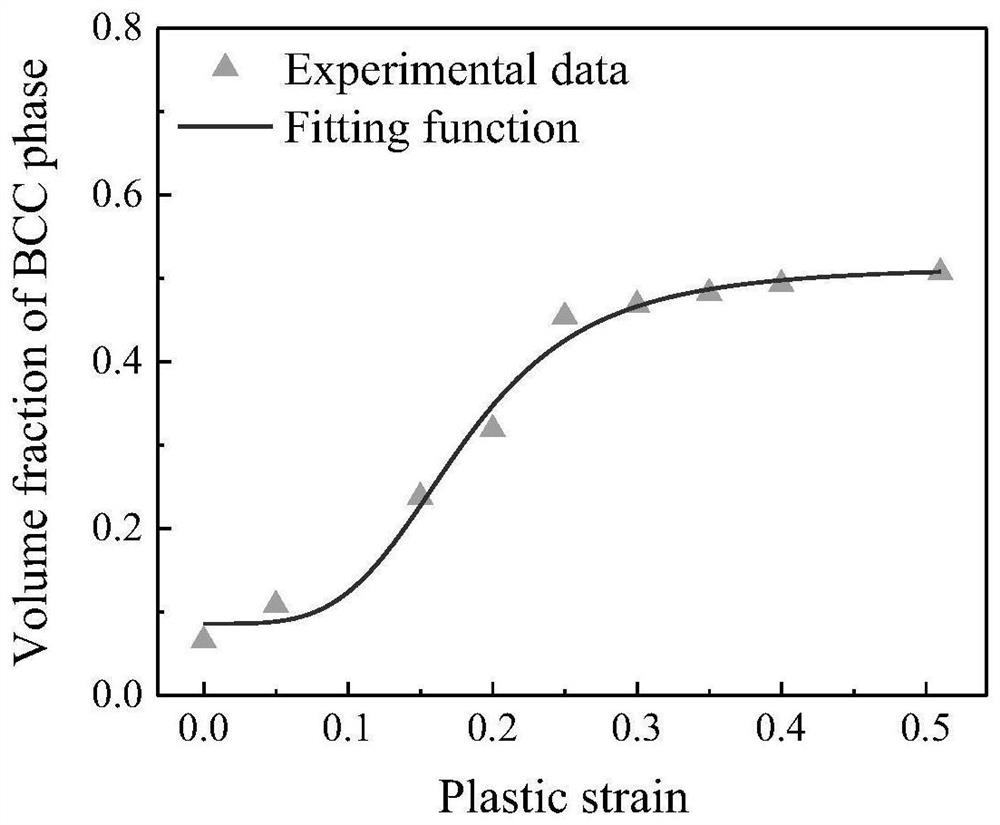

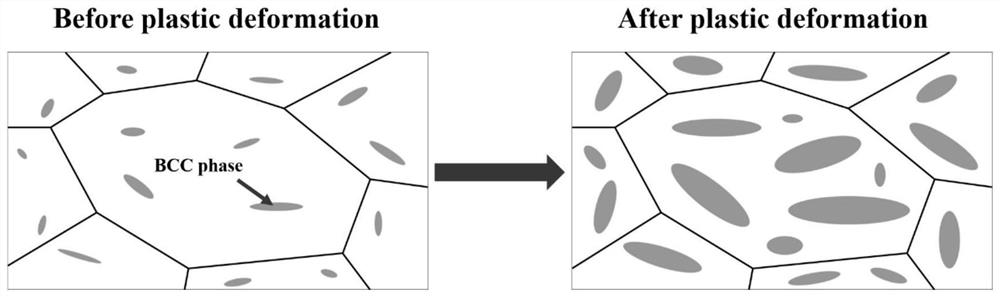

[0073] The following is attached figure 1 The given BCC phase volume fraction curve and attached figure 2 The schematic diagram of the BCC phase growth in the phase transformation process is given, a theoretical model and specific examples of the phase transformation strengthening of high-entropy alloys considering the four effects of lattice distortion, grain boundary, dislocation, and phase interface, and further elaboration on its technical scheme , the present invention is not limited to the following examples, and any design concept utilizing the present invention falls within the scope of protection of the present invention.

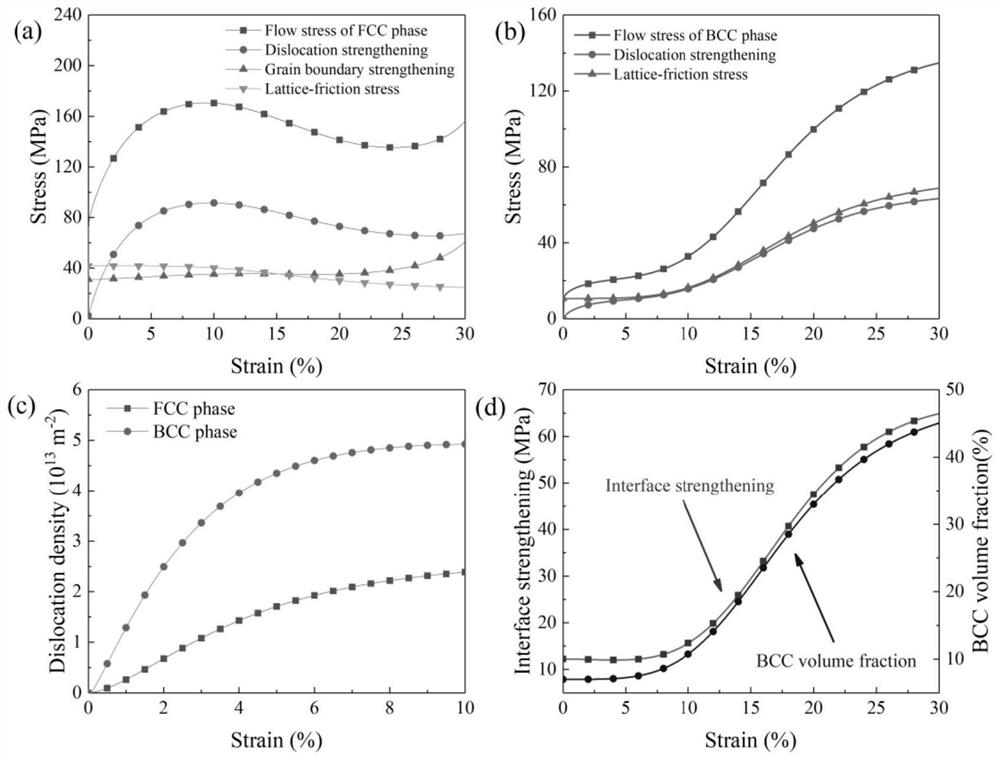

[0074] Lattice distortion is an inherent feature of high-entropy alloys due to the mismatch of the size and modulus of the constituent elements, which can strengthen the mechanical properties of the material; the grain boundary can hinder the dislocation and strengthen the mechanical properties of the material; It is easy to cross each other duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com