Austenitic stainless steel and manufacturing method thereof

A technology of austenitic system and manufacturing method, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of complex manufacturing process, inability to use stainless steel plates, and cost, and achieve the effect of reducing deviation

Active Publication Date: 2021-09-14

NIPPON STEEL STAINLESS STEEL CORP

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The method of manufacturing a stainless steel plate described in Patent Document 1 is a good method for manufacturing non-magnetic and high-strength parts, but has the following problems: the manufacturing process is complicated and costs are required; depending on the shape of the product, the manufactured stainless steel plate cannot be used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] One embodiment of the present invention will be described in detail below. It should be noted that the following description is for better understanding of the gist of the invention, and unless otherwise specified, does not limit the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

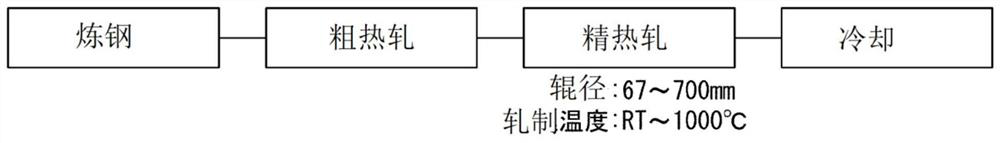

This method involves a coarse hot rolling step for performing coarse hot rolling after heating a slab manufactured by continuous casting to 1000-1300 DEG C, a finish hot rolling step for performing finish hot rolling on the manufactured steel strip after the coarse hot rolling step, and a cooling step for cooling the steel strip after the finish hot rolling step, wherein in the finish hot rolling step, the draft of the finish hot rolling is greater than or equal to 60%, the roll diameter of the finish hot rolling is greater than or equal to 300 mm, the temperature of the finish hot rolling is 600-1100 DEG C, and the final pass temperature of the finish hot rolling is 600-950 DEG C, and in the cooling step, if the final pass temperature of the finish hot rolling is greater than or equal to 750 DEG C, then the steel strip is cooled at a cooling speed of at least 5 DEG C / s until 750 DEG C.

Description

technical field [0001] The present invention relates to austenitic stainless steel and its manufacturing method. Background technique [0002] Portable electronic devices represented by smartphones have high demands for downsizing, lightening, and improving design. Therefore, in the manufacture of metal exterior members used in them, in order to cope with the processing of complex shapes, the implementation of It is a method of forming by cutting after severe cold forging. Furthermore, depending on the design of the portable electronic device, mirror polishing may be performed after the cutting process. Among them, exterior members of portable electronic devices are required not only to be non-magnetic in order to avoid adverse effects on geomagnetic sensors built in the devices themselves, but also to be high in strength. In addition, since the above-mentioned electronic devices are portable, they are often used in outdoor environments, and the exterior members also need ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/40C22C38/58C22C38/34C22C38/04C22C38/02C22C38/44C22C38/46C22C38/06C22C38/54C22C38/50C22C38/42C22C38/52C22C38/48C22C38/60C21D8/02

CPCC22C38/004C22C38/001C22C38/40C22C38/58C22C38/34C22C38/04C22C38/02C22C38/44C22C38/46C22C38/06C22C38/54C22C38/50C22C38/42C22C38/52C22C38/48C22C38/002C22C38/005C22C38/008C22C38/60C21D8/0226C21D2211/001B21B3/02C21D8/02C21D9/46C22C38/00C21D8/0263

Inventor 守本芳树平川直树沟口太一朗西村泰司

Owner NIPPON STEEL STAINLESS STEEL CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com