Manufacturing equipment and process of sanitary nursing mattress

A sanitary care and mattress technology, which is applied in the field of sanitary care products, can solve the problems of low fixation of polymer water-absorbing materials, non-absorbent parts of nursing mattresses, and uneven absorption of absorbent bodies, so as to reduce slippage, The effect of ensuring the stability of the pore size and improving the water absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-8 The application is described in further detail.

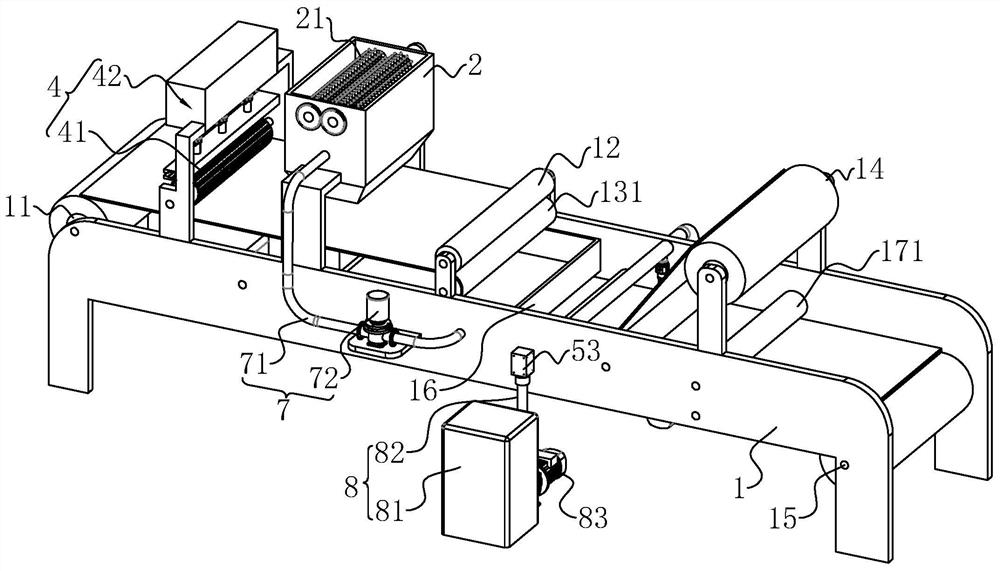

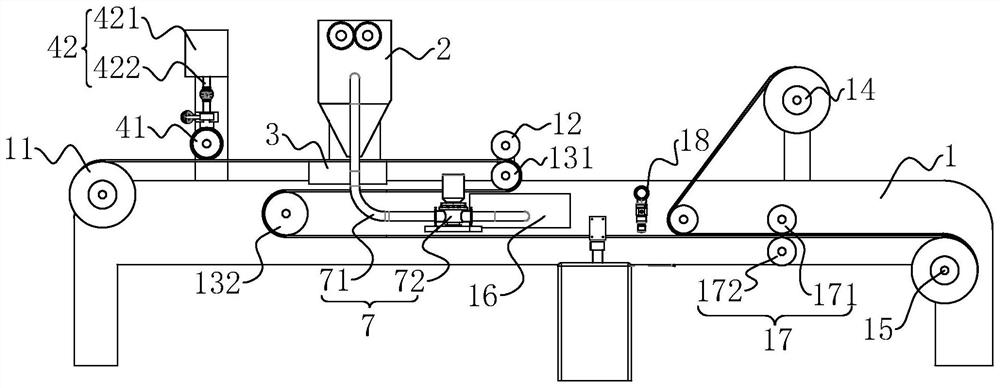

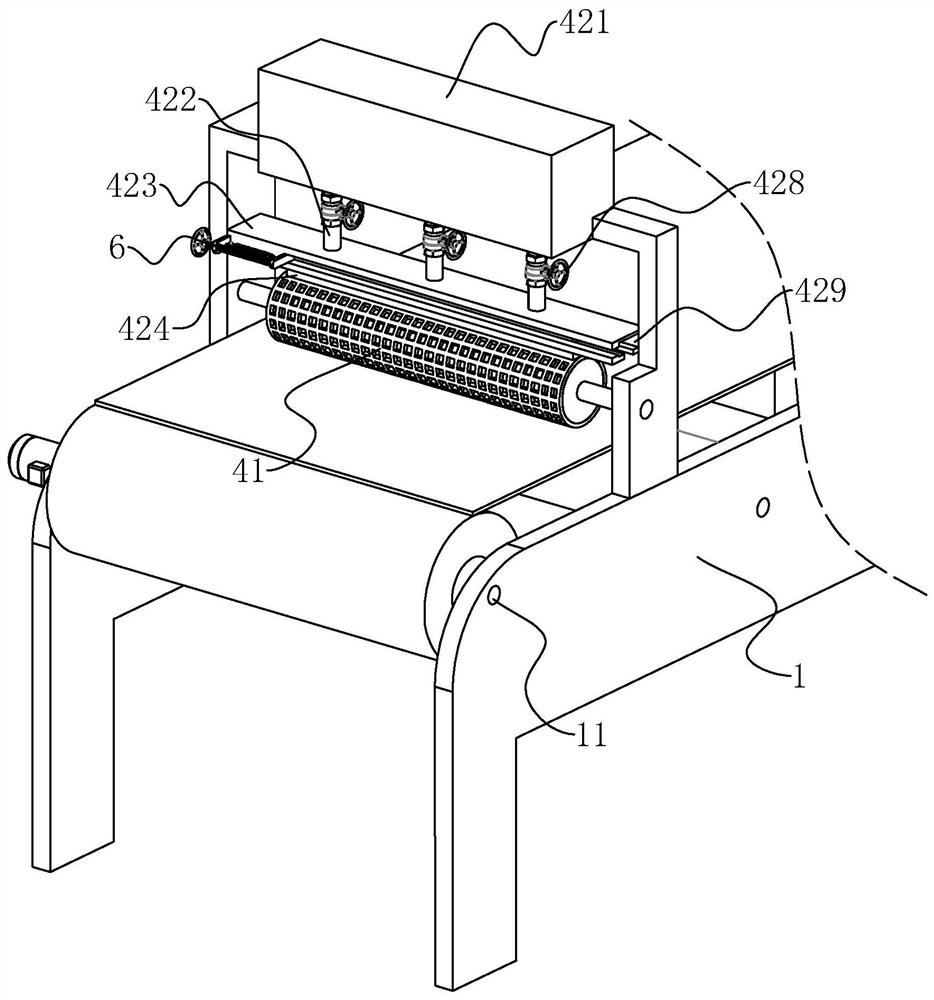

[0045] The embodiment of the present application discloses a manufacturing equipment of sanitary care mattresses, referring to figure 1 , figure 2 , including a machine body 1 for conveying the upper toilet paper and the lower toilet paper, a crushing bin 2 arranged on the body 1 to crush wood pulp into wood pulp fibers, an adsorption bed 3 located below the crushing bin 2, and an upstream of the crushing bin 2 for A gluing device 4 for gluing the surface of toilet paper and a polymer unloading roller located downstream of the pulverizing bin 2, and a pair of pulverizing rollers 21 are connected in rotation in the pulverizing bin 2.

[0046] refer to figure 1 , figure 2 The body 1 is rotatably connected with the first unwinding roller 11 located upstream of the gluing device 4 to unwind the lower toilet paper roll, the position-limiting initial pressure roller 12 located downst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com