Steel rail milling and grinding cutter and milling and grinding blade service life simulation experiment equipment and experiment method

A rail and milling technology, which is applied in the field of rail milling and grinding tools, can solve the problems of long test period, blade scrapping, track damage, etc., and achieve good milling effect, protection of the blade and track, and milling safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

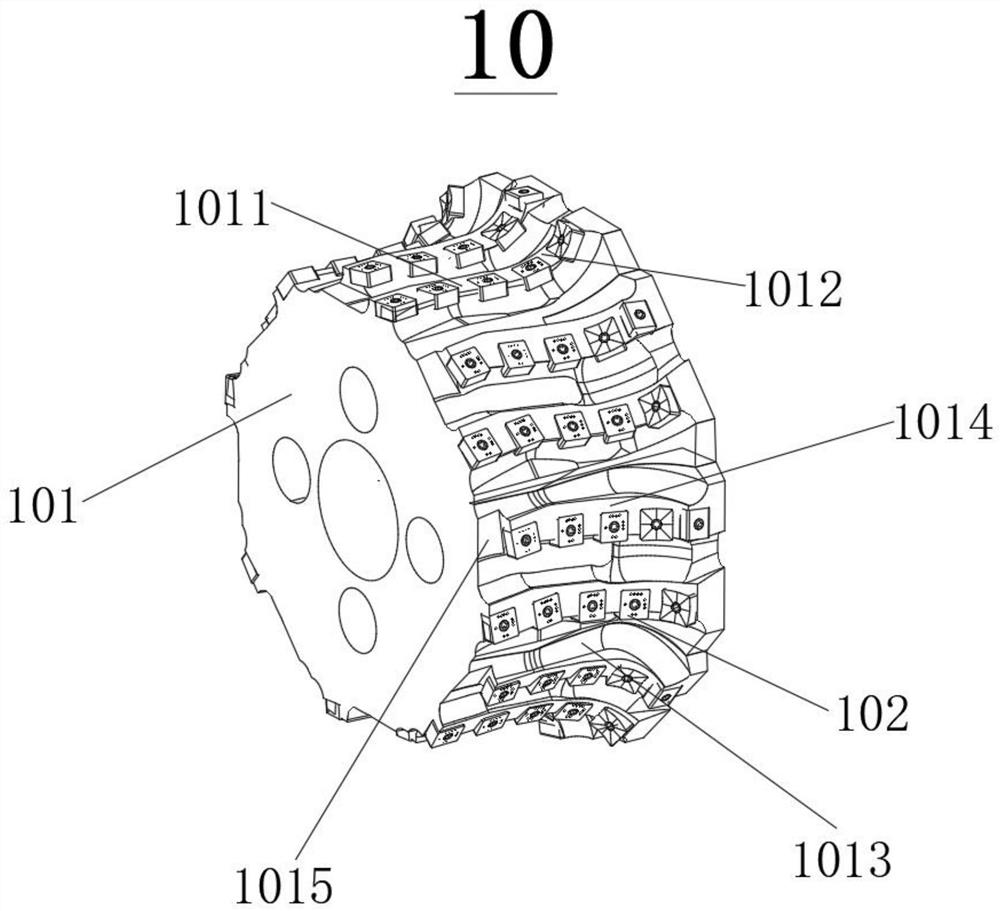

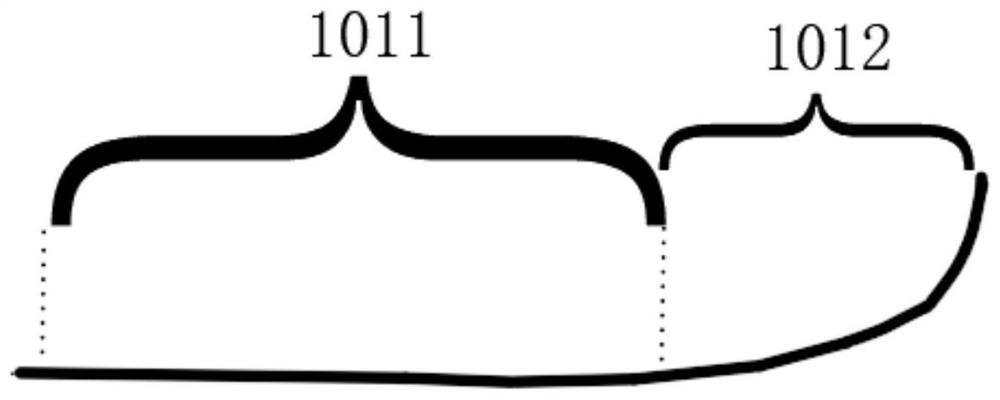

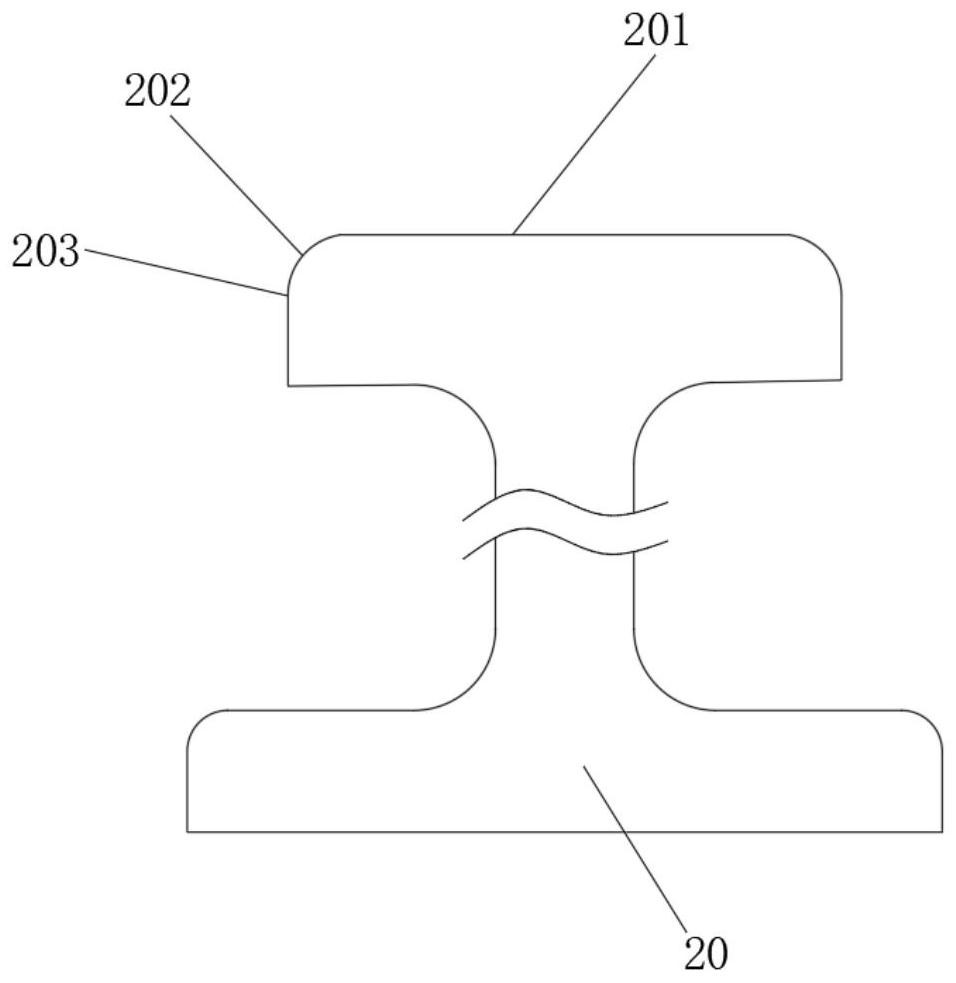

[0047] like figure 1 , figure 2 and image 3 As shown, the first embodiment of the present invention provides a rail milling tool 10, which at least includes a milling cutter disc 101 and several groups of milling cutter groups 102, and several groups of milling cutter groups 102 are arranged on the outer contour of the milling cutter disc 101 face.

[0048] When the rail milling and grinding tool 10 is in use, the milling cutter head 101 can be connected to the driving device through a connecting piece to drive its rotation. The driving device can be a common milling machine, grinding machine, drilling machine, etc., and several groups of milling cutter groups 102 are connected to The outside of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com