Processing technology for solving rough joint line of PET bottle preform

A processing technology and stitching technology, which is applied in the field of processing technology to solve the thick stitching of PET bottle embryos, can solve problems such as thick stitching, and achieve the effects of avoiding dislocation, ensuring appearance, and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

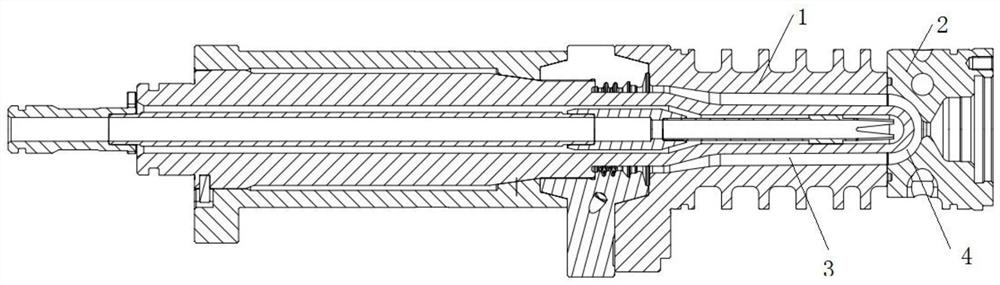

[0040] Such as Figure 1-7 shown, including the following steps:

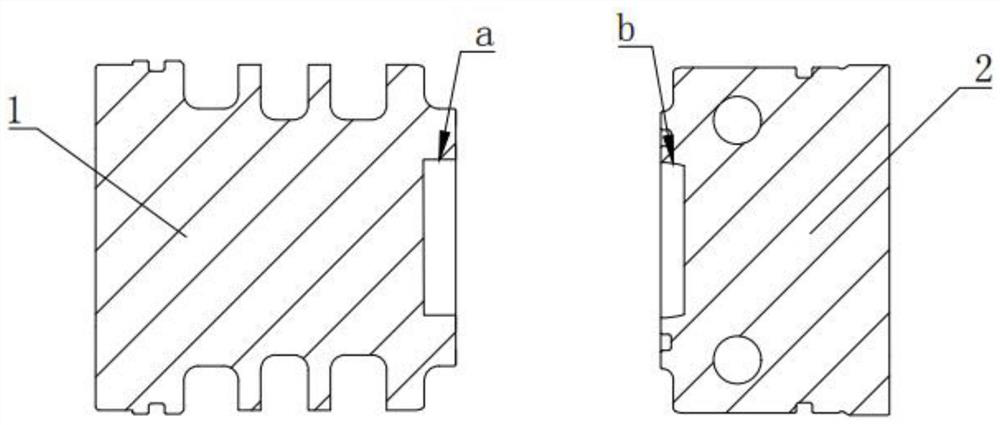

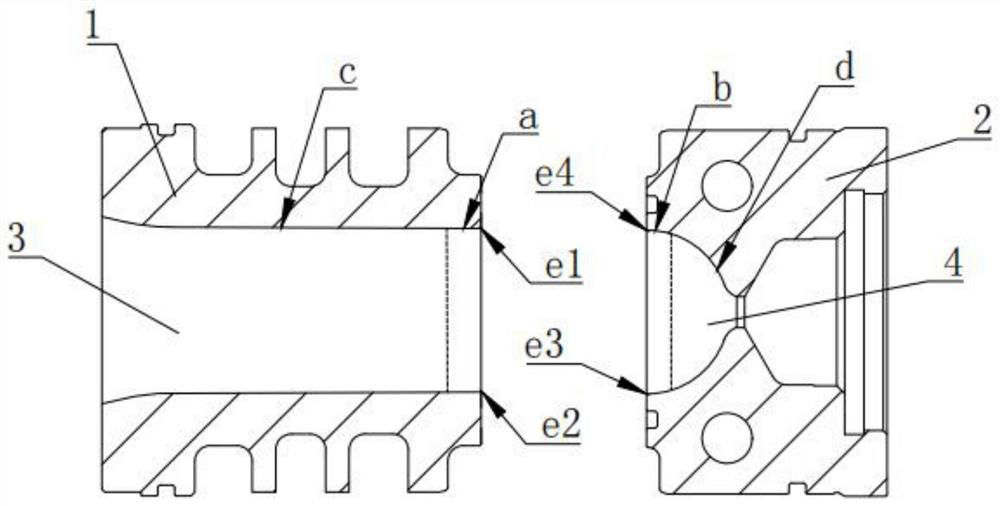

[0041] S1: Molding processing at the interface of the cavity to be formed; the interface of the cavity to be formed is ground to form the first forming section a along the axial direction, and the first forming section a is used as the positioning of the subsequent processing of the cavity to be formed Datum X, the depth of cylindrical grinding is 2mm; the first forming section a is as figure 2 shown.

[0042] Forming processing at the interface of the gate core to be formed; the interface of the gate core to be formed is ground to form the second forming section b along the axial direction, and the second forming section b is used as the follow-up of the gate core to be formed The processing positioning reference Y, the cylindrical grinding depth is 2mm; when the cavity and the gate core are docked, the first molding section a and the second molding section b form a smooth docking section; the second moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com