Ball refiner

A refiner and sphere technology, applied in the field of valve ball manufacturing, can solve the problems of cumbersome longitudinal rail plate movement, high motor running power, low machining accuracy, etc., and achieve the effect of avoiding product scrap, prolonging service life, and uniform automatic grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

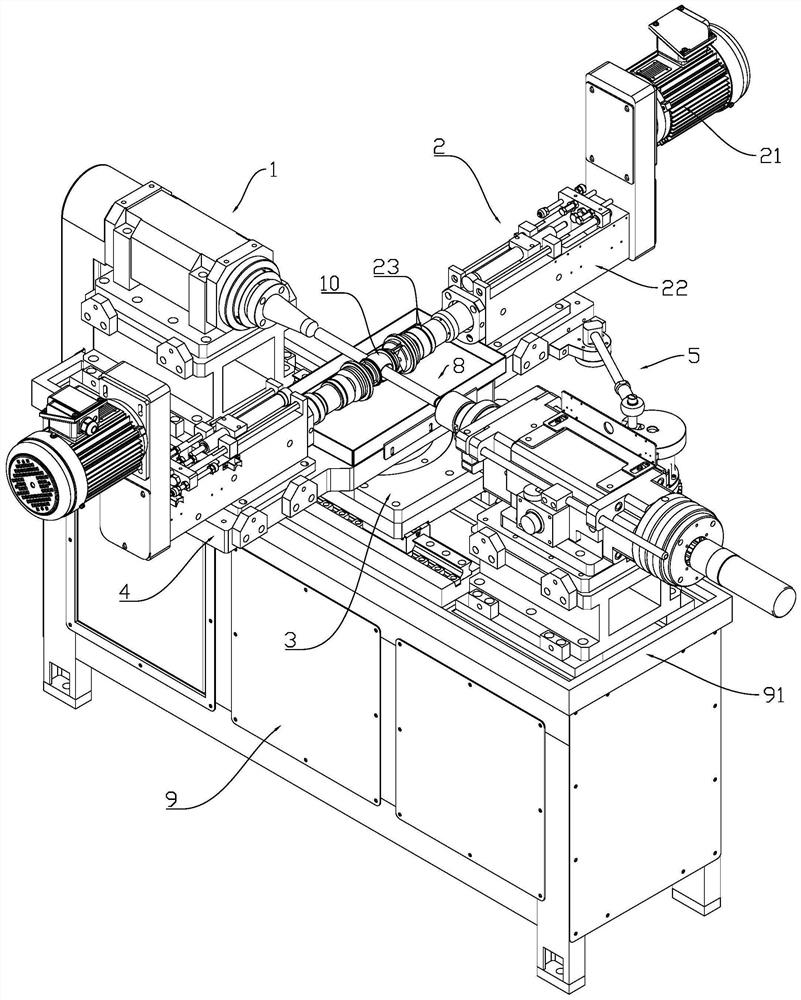

[0053] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing, refer to Figure 1-Figure 18 .

[0054] Such as figure 1 As shown, a ball refiner includes a frame 9, an organic base 91 is arranged on the top of the frame, and a steering mechanism 1 for fixing and rotating the sphere 10 is installed on the frame 91, and a steering mechanism 1 for grinding the sphere 10 is installed on the frame 91. The grinding mechanism 2 and the swinging mechanism 5, the grinding mechanism 2 and the steering mechanism 1 are arranged in a staggered manner. The base 9 is equipped with a mounting seat 3 for moving, and a rotating seat 4 is installed on the mounting seat 3, and the grinding mechanism 2 is installed on the rotating seat 4; the swing mechanism 5 is connected with the rotating seat 4 for driving The rotating base 4 swings back and forth.

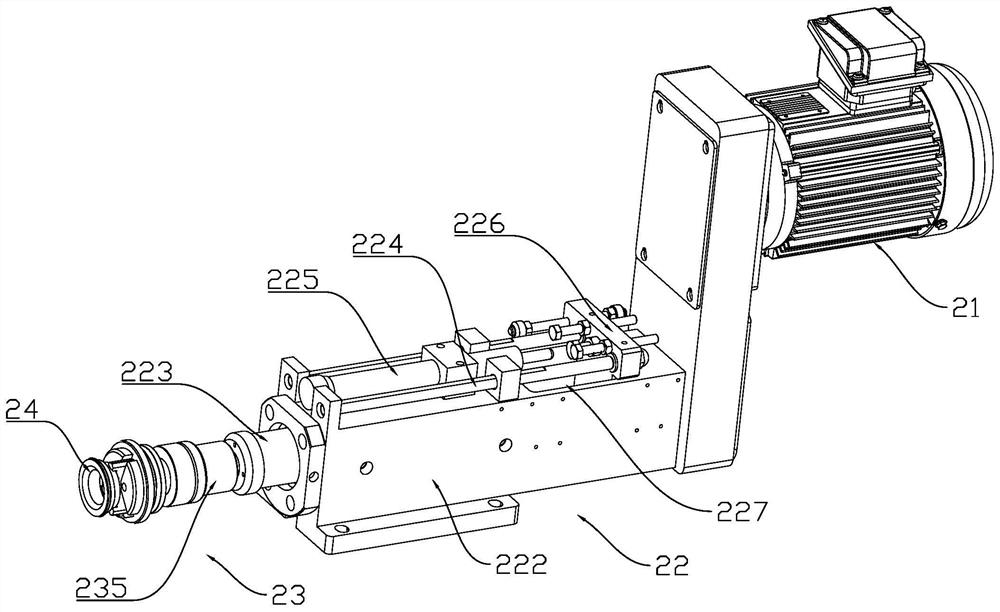

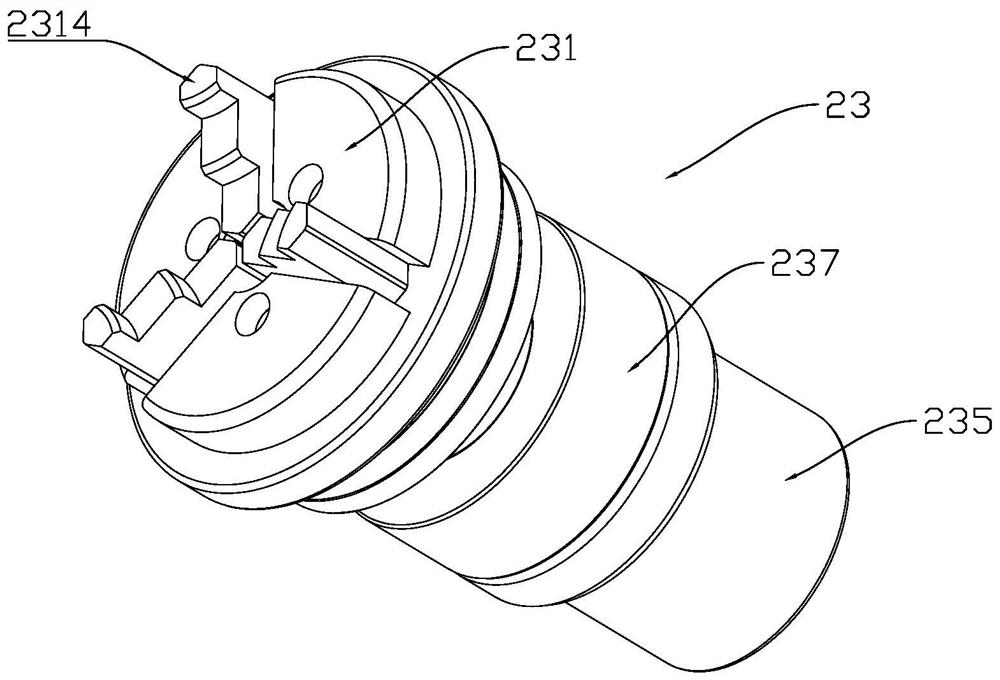

[0055] Grinding mechanism:

[0056] The grinding mechanism 2 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com