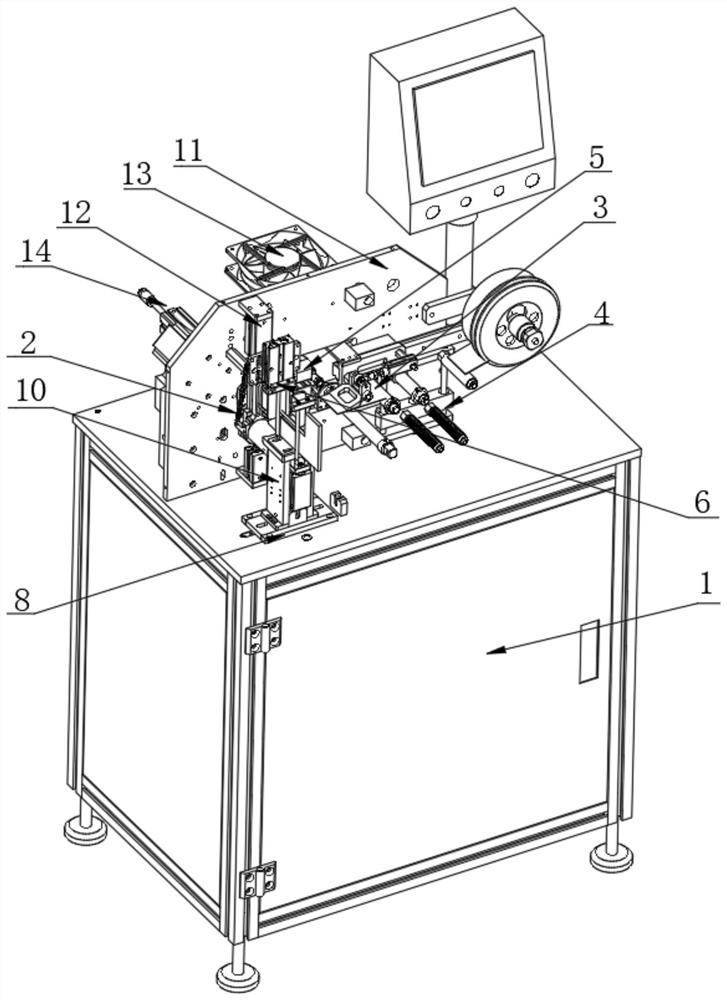

Electric hard bar adhesive tape winding machine

A technology of electric power and glue machine, which is applied in the field of electric power and can solve the problems of low efficiency and high cost of electric hard-discharge and winding glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

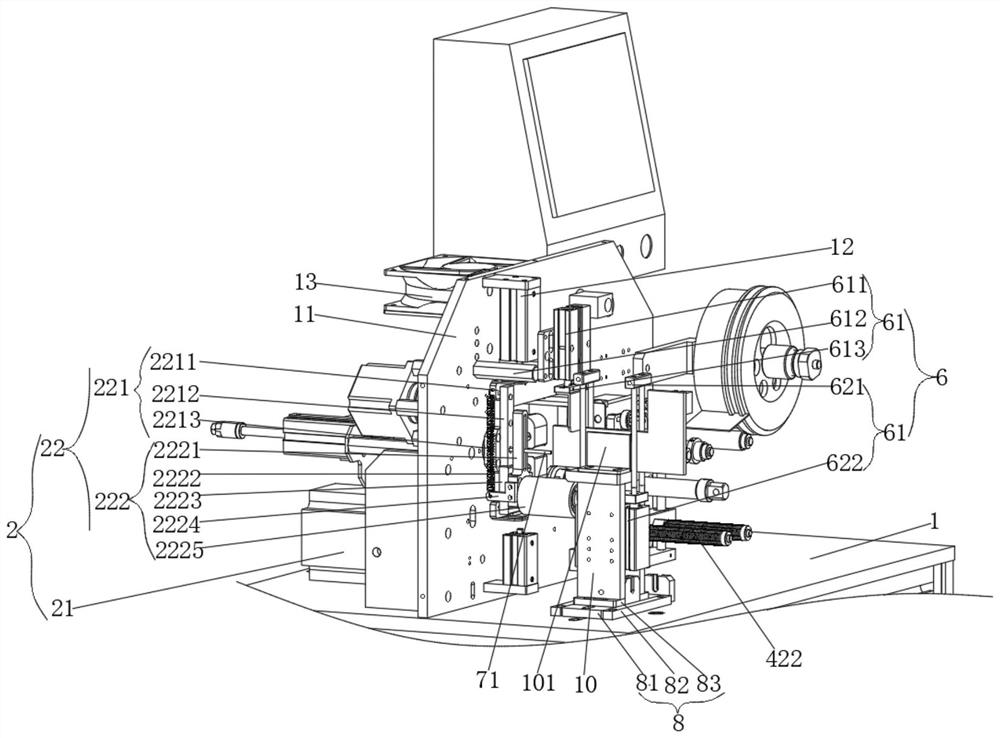

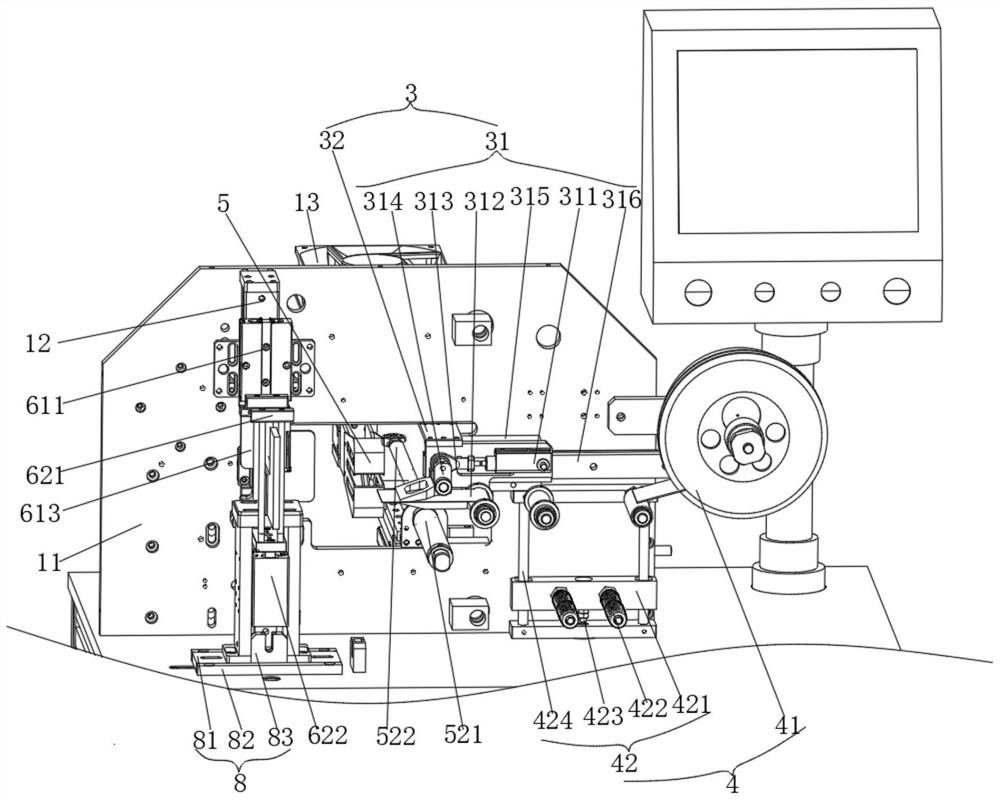

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0036] Power hard row is a high-current conductive product, which is suitable for electrical engineering such as high and low voltage electrical appliances, switch contacts, power distribution equipment, and busway.

[0037] At present, it is usually necessary to spray insulators to the outside during the use of the power hard row. Since the two ends of the power hard row are conductors connected to the electricity, during the spraying process, if the two ends are sprayed on the insulator, it will inevitably affect the connection with the external equipment. The effect of electricity causes the circuit to be blocked. In the existing spraying process of the power hard row, it is usually used to manually wrap the tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com