A kind of near-infrared laser ignition energetic material and its preparation method

A laser ignition and near-infrared technology, used in offensive equipment, explosives processing equipment, explosives, etc., can solve the problems of unstable performance, poor preparation process safety, and increase the mechanical sensitivity of the target composite material.

Active Publication Date: 2022-06-03

INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the composite energetic material prepared by this method has the disadvantages of unstable performance and poor preparation process safety.

At the same time, adding harder components (metal nano-ions) to explosives will also increase the mechanical sensitivity of the target composite and reduce its safety performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

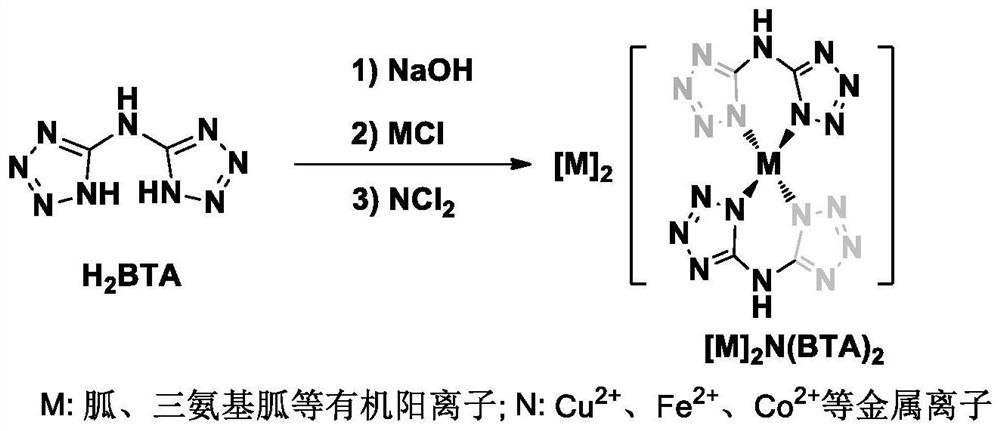

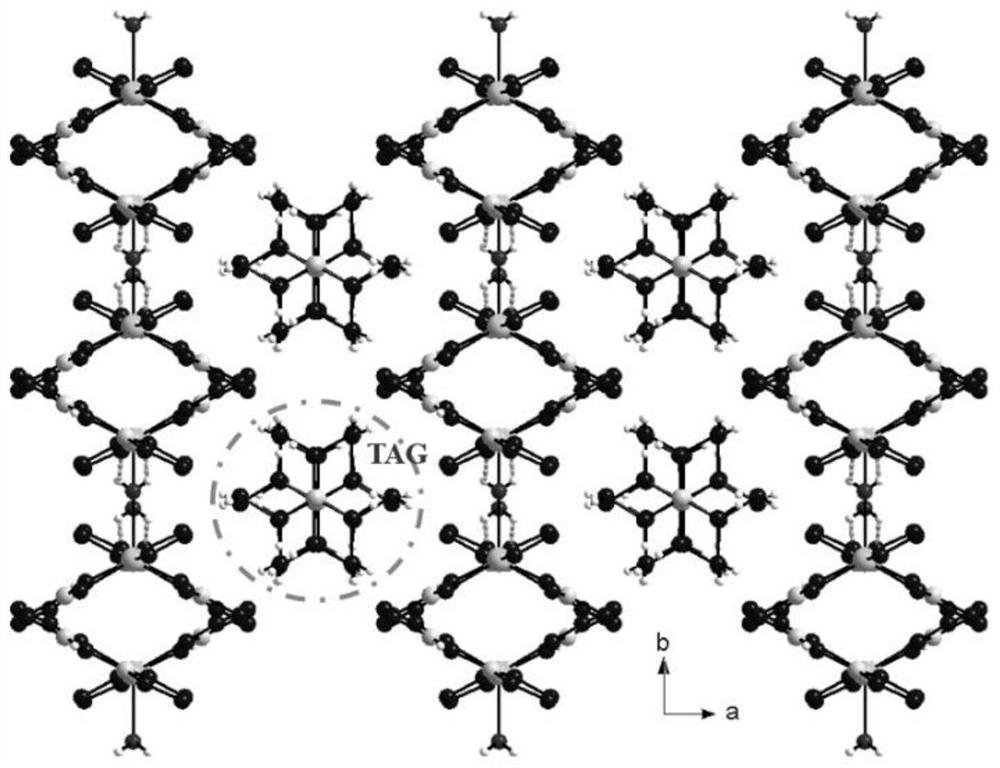

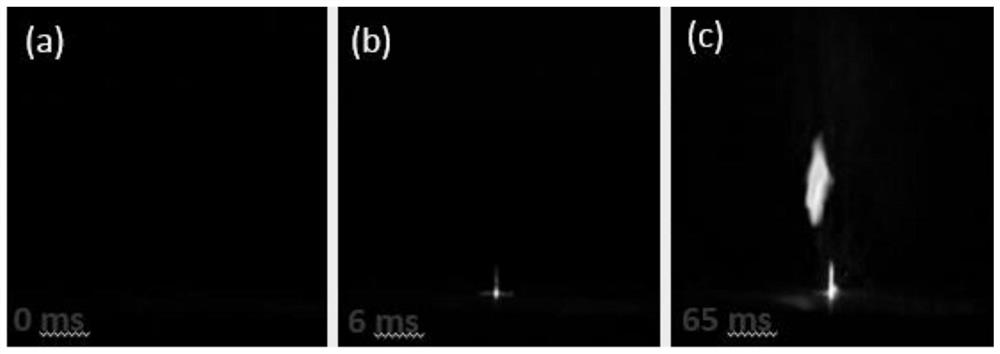

The invention discloses a preparation method of an energetic material ignited by a near-infrared laser, which comprises the following steps: dissolving an energetic metal-organic coordination framework material into water at a certain temperature, and then adding CHNO high-energy explosive crystals; standing at room temperature In 1 to 2 days, a new type of energetic material with a layer of energetic metal-organic framework material grown on the surface of the CHNO high-energy explosive crystal is obtained, that is, the target energetic material. The novel energetic material provided by the invention can promote the rapid development of laser ignition technology, and also provide new ideas for the development of novel laser ignition energetic materials.

Description

A kind of near-infrared laser ignition energetic material and preparation method thereof technical field The present invention relates to energetic material technical field, be specifically related to a kind of near-infrared laser ignition energetic material and preparation thereof method. Background technique [0002] The laser ignition mechanism of energetic materials can be divided into two types: photothermal effect mechanism and laser direct dissociation mechanism. in, The mechanism of the photothermal effect is that the molecules of the energetic material instantly generate high-energy heat by absorbing the energy of the laser photon, thereby triggering the energetic Material ignites. The mechanism of direct laser dissociation means that the molecules of energetic materials absorb laser photons of a specific frequency and dissociate, resulting in into highly reactive molecular fragments, thereby triggering a chemical chain reaction and realizing the ignition of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C06B45/24C06B21/00

CPCC06B45/24C06B21/0083Y02P20/54

Inventor 王康才张庆华

Owner INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com