Cannabidiol purification device and purification method thereof

A technology of cannabidiol and a purification method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as troublesome filtration, and achieve the effect of saving occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

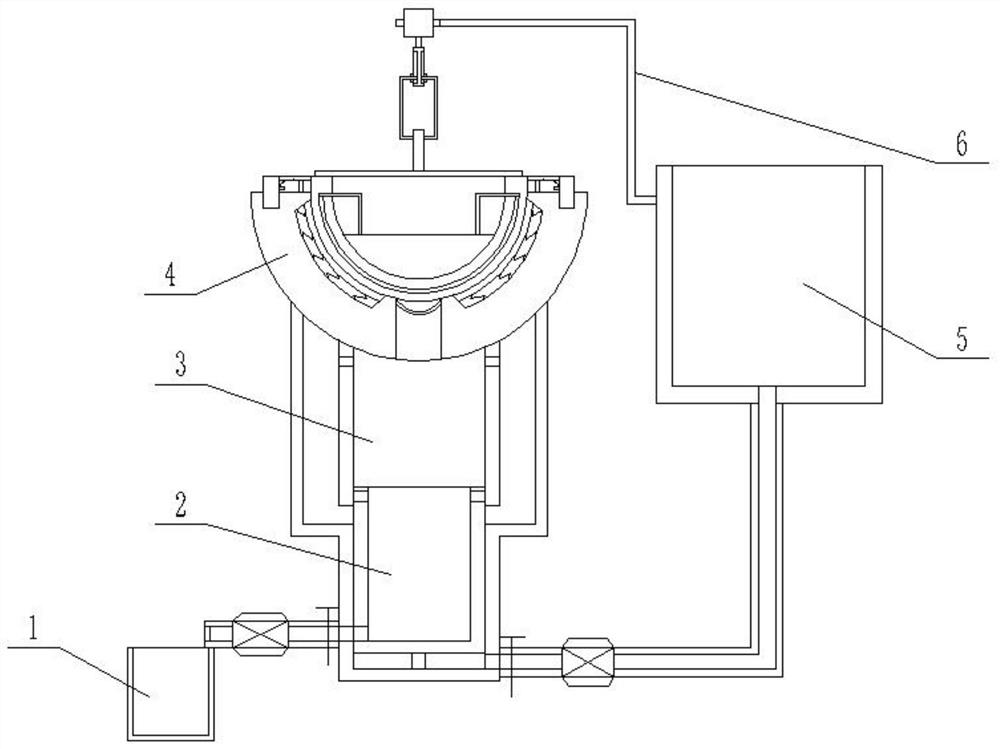

[0019] Specific implementation mode one: as Figure 1-10 As shown, this embodiment describes a mold fixing and limiting device for mechanical processing, including a collection container 1, a movable device 2, a fixing device 3, a pretreatment device 4, a liquid storage device 5 and a bracket 6; the pretreatment device The lower end of 4 is fixedly connected with a fixing device 3, and the inside of the fixing device 3 is provided with a movable device 2; the collection container 1 is placed at the lower end of the fixing device 3; the liquid storage device 5 is fixedly connected to the side of the fixing device 3; One end of the bracket 6 is fixedly connected to the liquid storage device 5 , and the other end of the bracket 6 is fixedly connected to the pretreatment device 4 .

specific Embodiment approach 2

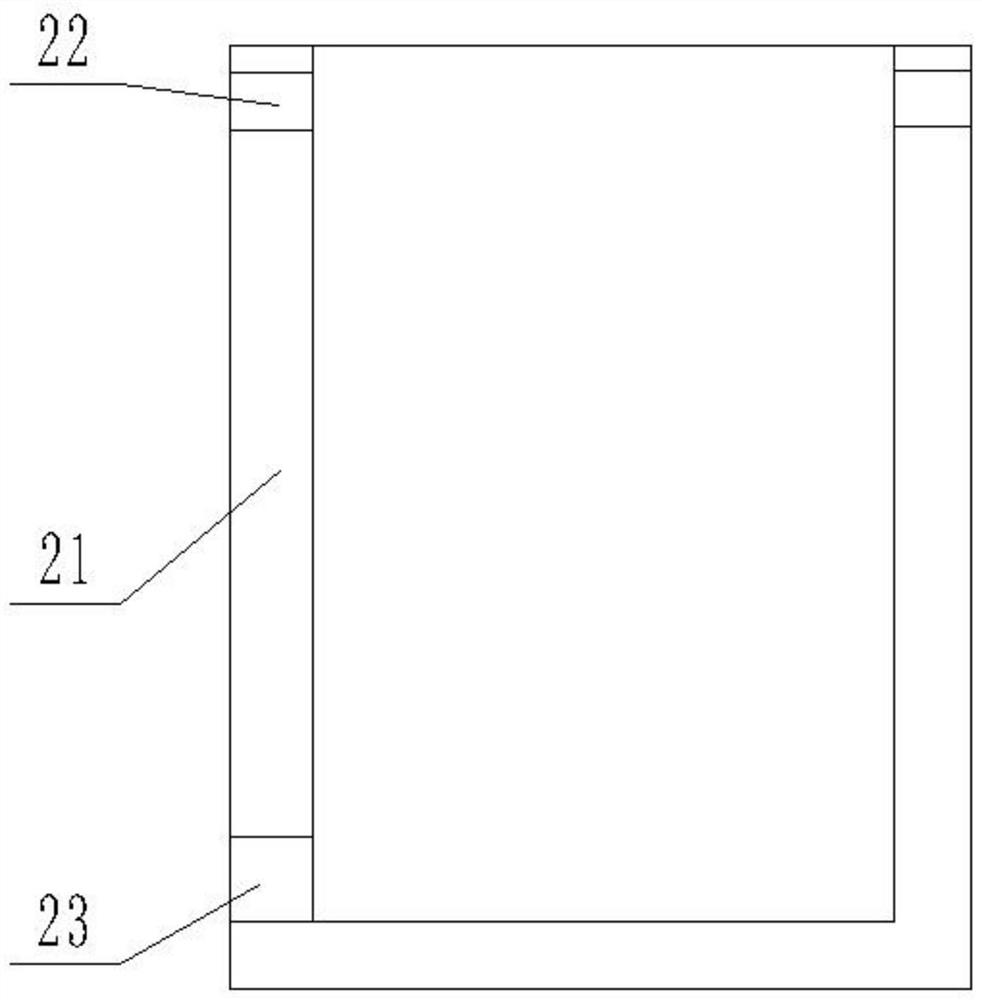

[0020] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of specific embodiment one. The movable device 2 includes a movable cylinder 21; Two feed holes 22 are provided.

specific Embodiment approach 3

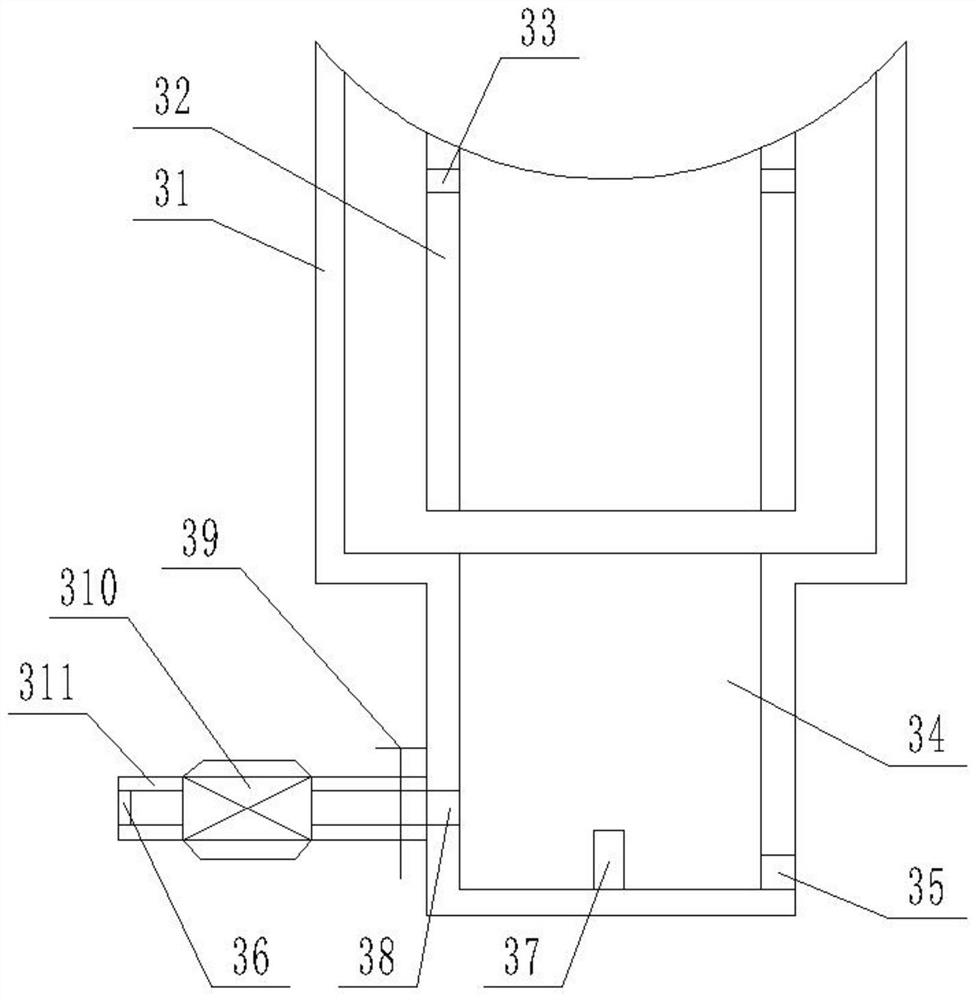

[0021] Specific implementation mode three: as image 3 As shown, this embodiment is a further description of Embodiment 1. The fixing device 3 includes a cylinder I31, a cylinder II32, a cylinder III34, a filter screen 36, a support column 37, a valve I39, a water pump I310 and pipelines I311; the upper end of the cylinder III34 is fixedly connected with the cylinder I31, and the inner diameter of the cylinder I31 is larger than the outer diameter of the cylinder III34, and the two sides of the bottom end of the cylinder III34 are respectively provided with a through hole I35 and a through hole II38. The height of the hole II38 is higher than the through hole I35; the tops of the cylinder I31 and the cylinder II32 are fixedly connected with the pretreatment device 4, the cylinder II32 is arranged inside the cylinder I31, and the outer diameter of the cylinder II32 is smaller than the cylinder The inner diameter of I31, and there is a gap between the lower end of the cylinder I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com