Parallel tooth sliding stepless speed change device

A technology of continuously variable transmission and parallel teeth, which is applied in the direction of gear transmission, transmission, transmission control, etc., can solve the problems of unable to meet the needs of speed change, long switching time, small initial torque, etc., and achieve simple structure and low cost of use low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

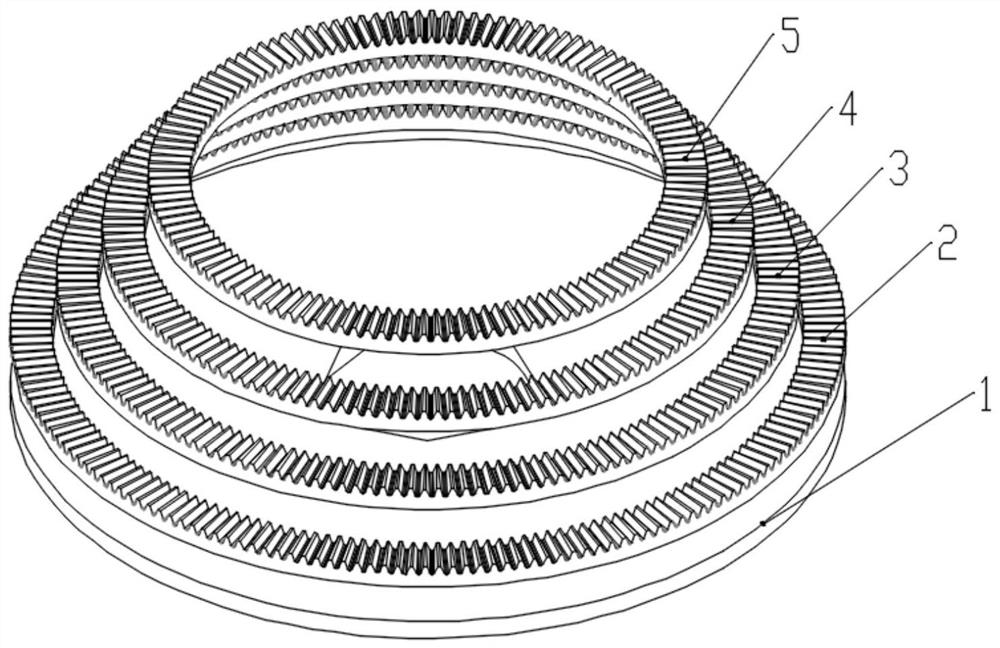

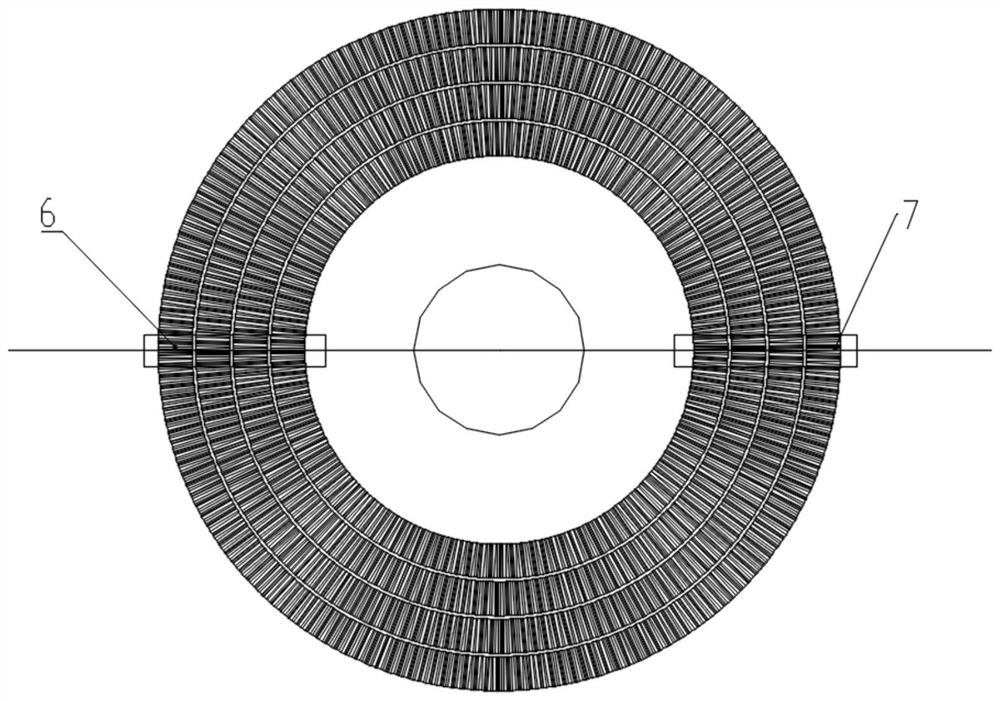

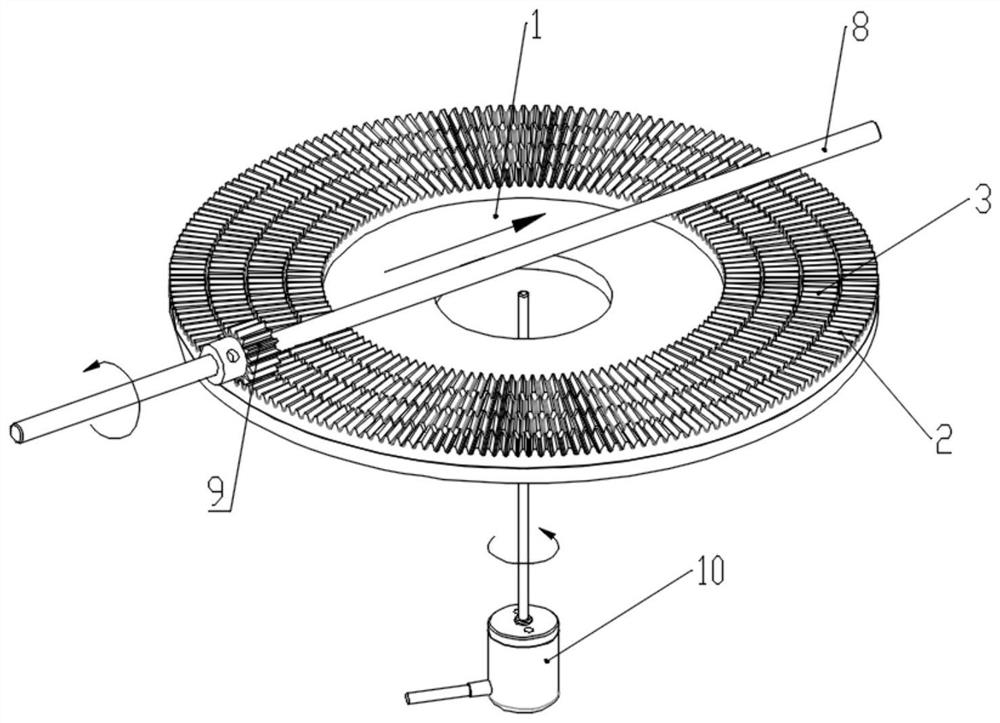

[0039] Example 1: Combining Figure 1 to Figure 6 , install servo motor 13, screw mandrel 14, slide table 15 and guide rod 17 on bracket 19, slide table 15 is fixed on the screw rod 14 and guide rod 17, and one end of screw mandrel is connected with servo motor; Simultaneously on slide table Install the transmission motor 12, install the synchronous wheel on the output shaft, connect the synchronous wheel and the transmission motor through the synchronous belt 16, the transmission motor drives the output shaft to rotate through the synchronous belt, and the output shaft drives the driving gear to rotate; in this case, set the ring gear The number is four, respectively ring gear 1 2, ring gear 2 3, ring gear 3 4 and ring gear 4 5, set the width of ring gear 1 2, ring gear 2 3, ring gear 3 4, and ring gear 4 5 to 1cm and the interval between them is 0.1cm. When the circumference of ring gear 1 is determined to be 2*π*9.5=59.66cm, the transmission circles of ring gear 2 3, ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com