Aviation plate position sensor automatic test equipment and control method

A technology of automatic testing equipment and sensors, applied in the direction of instruments, etc., can solve the problems of heavy workload, increased human error, low efficiency, etc., and achieve the effect of stabilizing the input voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

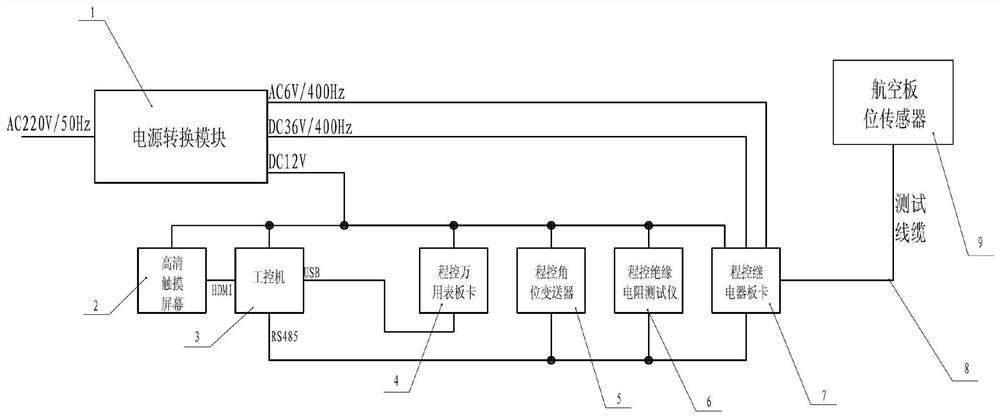

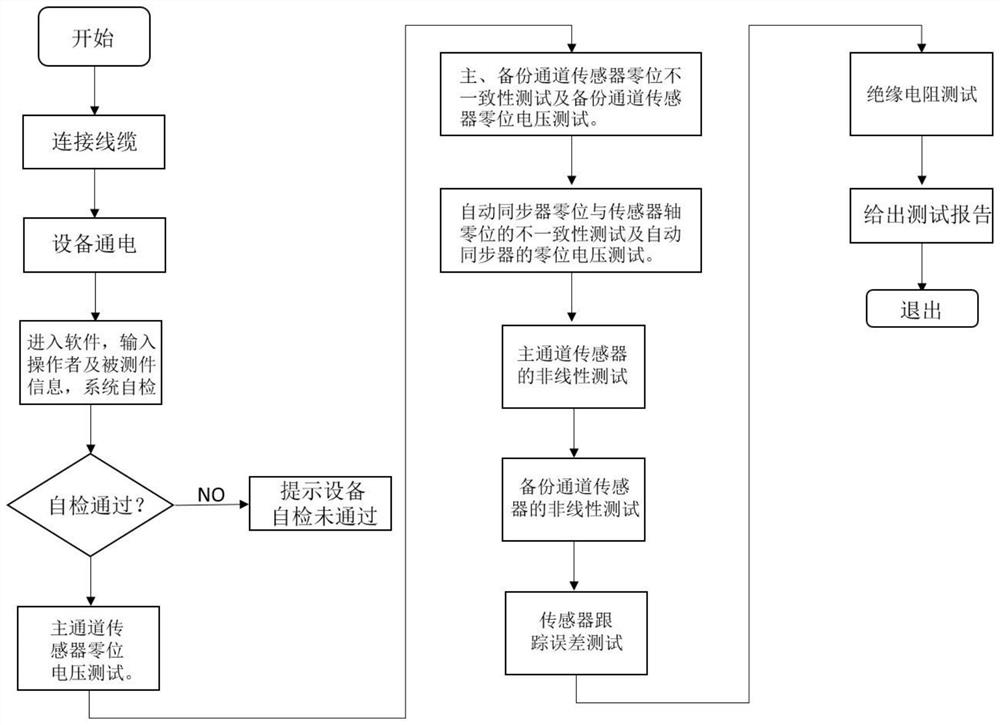

[0035] like figure 1 and figure 2 As shown, an automatic test equipment for aviation board position sensors, including an industrial control platform for the control of the entire equipment, also includes:

[0036] The test module, in cooperation with the industrial control platform, can detect and record the output voltage of the main channel sensor, the backup channel sensor, and the automatic synchronizer, the output angle value of the sensor, and the insulation resistance value between the pins of the sensor;

[0037] The line control module cooperates with the test module and connects with the aviation board position sensor 9 through the test cable 8, and can automatically select the corresponding line according to the test software process of the host computer to complete the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com