A Multiphase Fluid Measurement System Based on Standpipe Differential Pressure

A technology of fluid measurement and differential pressure flowmeter, which is applied in the direction of liquid/fluid solid measurement, measurement, and detection of fluid flow by measuring differential pressure. It can solve the problems of high later cost, radioactive source environment, and human hazards. Low price, high detection efficiency, and the effect of real-time online detection of detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

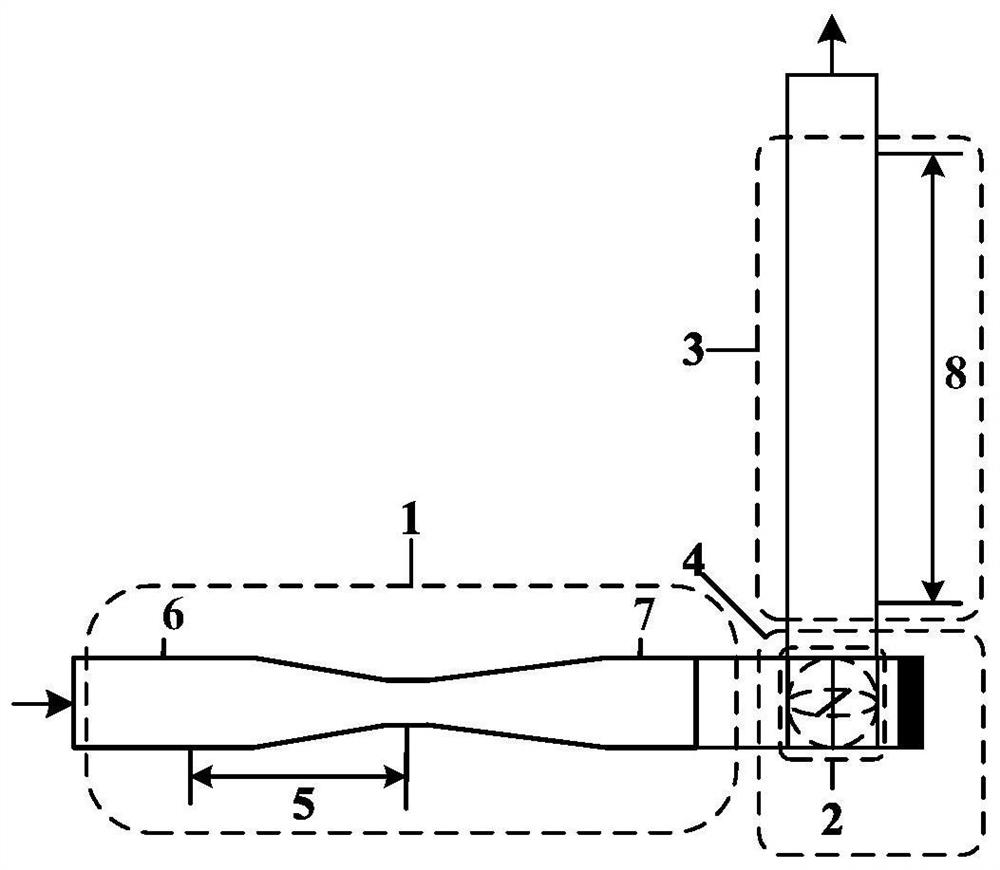

[0085] Reference Figure 11 Another embodiment of the present application provides a virtual metering device based on an oilfield site already having sensors for three-phase flow of oil and gas water, Figure 11 The meaning of each number in the Figure 1 Similarly, but in this embodiment of the differential pressure flowmeter module 1 in the venturi tube is replaced with an existing, valve-like throttle member already in the field, pressure sensor 6, temperature sensor 7, and riser differential pressure flowmeter module 3 in the riser differential pressure sensor 8, also as far as possible by the existing sensor data in the field to replace, thereby reducing the site hardware cost and installation cost as much as possible. Data processing and acquisition modules and display modules may also be replaced by microcomputers already in place. By combining the data provided by the above-mentioned differential pressure flowmeter module 1 and the riser differential pressure density meter mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com